daily use product cheap Molding machine Plastic injection molders plastic mould maker

- Category: >>>

- Supplier: INTERTECH MACHINERY INCORPORATIONINTERTECH INCORPORATION

Share on (60423261427):

Product Overview

Description

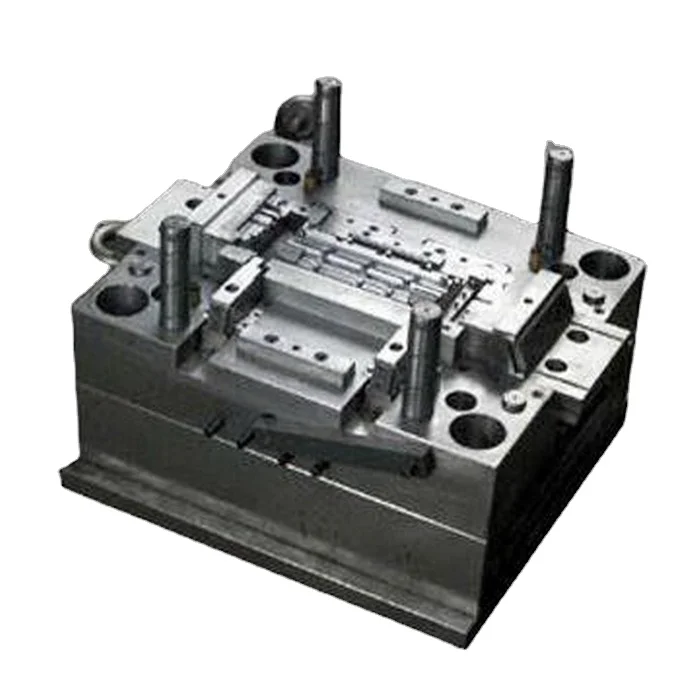

cheap Molding machine Plastic injection molders

Characteristic:

1. Design to production of mold, 100% made in Taiwan.

2. The SGS RoHS Certification Mark demonstrates our commitment to quality and achieving consistent production.

3. Excellent in interchangeable cores molds design.

4. Surface finish with high gloss polishing.

About us:

1. We are a flexible customized mold making, molding factory and have complete production line from A to Z.

2. Our company aims at carrying out customers’ designs and especially good at OEM manufacturing, Contract manufacturing.

3. We are particularly specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production.

4. Our team has efficient communication, experienced engineers, and all of our mold steels imported from German, Japan, and Sweden.

Our Professionals:

1. Making interchangeable cores mold : a most effective and cost-saving manufacturing process. Suitable for customers looking for “more variety but less quantity” solution. With only one mold, it can efficiently generate different kinds of products,

2. Making high transparent PC, Acrylic, PMMA, PET.. parts mold with high gloss polishing and Mold-Tech texture on parts surface, applied mostly in lighting parts, outdoor LED parts projects.

3. Making gas assisted injection molds and products projects …mostly applied in projects like the thick handles, monitors, the frame of TV cabinet etc, which prevents the shrinkage mark, improves the strength of the parts and saves material costs.

4 Medical silicone and rubber molds/products making : We manage both “solid” and “liquid” silicone rubber material meeting the standard of RoHS, and REACH, and can be applied like skincare parts, medical earplugs, nipple pacifier, check valve, diving mask.

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

Production Flow

About Us:

In short, Intertech (Taiwan) provides an extensie integrated operational ability from design to production of molds 100% made in Taiwan.

With the performance level in Taiwan, we satisfy our world customers with the best value of mold making workmanship: customer design service; prototyping; mold making; manufacturing process control; reverse engineering; customer molding & assembly...etc.

We manufacture plastic injection molds, die-casting molds, silicone rubber molds, liquid silicone rubber molds, LSR molds, rubber molds, press molds and hot runner molds (MoldMaster, MasterFlow, LKM, Incoe systems...etc).

We are particularly specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production...etc.

To know us more, please visit www.taiwanmoldmaker.com; www.intertech.net.tw

1. Customized Making:

- Per your drawings or samples, we can customize your mold.

- Per your requirement, we can modify and design your parts structure to establish the overall 3D effect drawing. And per above 3D drawing, we can provide mold making quotation and product molding quotation to you to help you to do the entire costing analysis.

2. Prototype Making:

- in initial stage, after confirming the product design, size, material, and price…etc, if you need, before starting to make the real mold, we can make the prototype for you to help you understanding the product detail and its outlooking (Ps. we will estimate the prototype cost report to you from 3D printing or from NC milling way).

3. Purchase Contract Making:

If both of us agree to sign the contract, we will mention the working detail, lead time, inspection standard, payment term information…etc on the contract.

4. During the mold manufacturing period:

- We will send the update working progress report in every 1-2 week with photos.

- Before commencing making the mold and the machining process, if customer needs to adjust the product’s shape slightly, we will not charge the extra cost.

-If the machining process is on-going, and customer needs to adjust the product design, we will study and give our report to see whether we should charge extra cost or not.

-We will send T1, T2 or T3 samples till meeting customer’s satisfaction.

5. If customer places the product production orders to us:

- After the final trial samples is approval by customer, if customer places the product production to us, we will be responsible for the mold maintenance and performance for all.

6. Packing information:

- For mold, we pack with standard exported wooden box with fumigation process.

- For product, if there is no specific packing requirement, we will use regular carton box and bag (free of charge). If customer requires specific packing way,

We can help customer to do the assembly, packing and the printing from case to case.

7. Transportation:

- Customers can use their own forwarder or we can help customer to arrange any sea or air transportation forwarder to deliver the goods to customer’s address.

For Parts: bulk or individual pack, upon customer's demands with exported carton box.

For Mold: Standard exported wooden box packed, fumigation process (upon required).

1. Besides molds, do you generate products as well?

Yes, we can make your projects here in our factory, Taiwan for you. But we only make it from making a new mold...then, from above new mold, making parts out of it. We make the production job for our customers in Taiwan. In other words, we do not have any existing mold. In short, we produced customized molds and products but we also provide our customers reverse engineering service.

2. How can I get the quote?

First, we need our customers provide their technical data like 2D, 3D drawings or samples. After receiving your project, our experienced and professional team will start to study and evaluate it. During this time, our team will keep discussing with the designers to make sure that every details are clear. Finally, we will give our customers quotation reports.

3. Does your company provide design service?

Absolutely yes. We have helped countless customers from Europe and North American to invent their new products. Our experienced engineers give our customers useful suggestion to help them solve the problems that they encounter when designing and process the molds and products.

4. Why is your price not so competitive?

First of all, what we are famous for is that we produce interchangeable core mold, which needs not only precision work but also flexible team work to adjust to what our clients really want. Also, all of our steel is from Japan and Germany and all processing steps are carried in Taiwan under the supervision of our professional engineers. We appreciate that all of our customers emphasized on quality and efficiency and that's why our company wants provide too.

To know us more please contact us with your ideas / projects / drawings, so that we can start our studying / engineering job...

To know us more, please visit

www.taiwanmoldmaker.com; www.intertech.net.tw

We Recommend

New Arrivals

New products from manufacturers at wholesale prices