Easy Open End for Food Cans,Tinplate EOE Aluminum EOE Production Line

- Category: >>>

- Supplier: Jiujiang Gaoxin Metals Packing Mechanism Co. Ltd.

Share on (60508668861):

Product Overview

Description

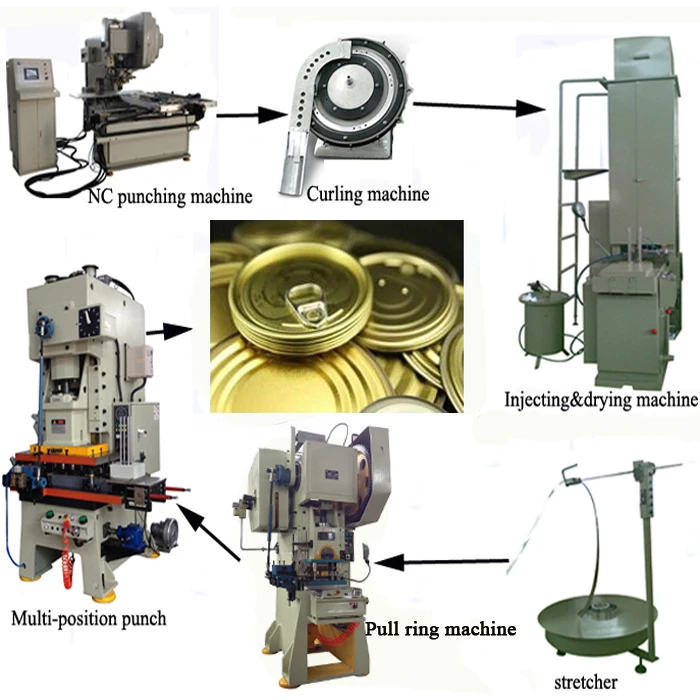

Easy Open End for Food Cans,Tinplate EOE Aluminum EOE Production Line

Easy Open End for Food Cans,Tinplate EOE Aluminum EOE Production Line

Easy Open End for Food Cans,Tinplate EOE Aluminum EOE Production Line

1)Stretcher for plate

Usage:It is used to stretch the sheet for the next working procedure of making ring pull.

2)25T open punch+progressive die(Ring-pull machine)

| Production Capacity | 80-120pcs/min |

| Nominal pressure | 25T |

| Motor power | 3KW |

| Overall Dimension | 1200*1000*1800mm |

| Weight | 2600kg |

Usage:25T punch equipped with progressive die is used to punch into shape of ring pull.

3)GT2A8 Multi-position punch(Easy-open cover combination machine)

| Slide Stroke | 12.5-120mm |

| Times of Slide Stroke | 90-110/min |

| Power | 5.5KW |

| Weight | 8000kg |

| Worktable | 850*500mm |

Usage:

The function of the machine is closed to multi-position press machine which can complete the working procedures of embossing, ruling and riveting in a stroke for the forming of easy open lid/cover.

4)NCP-008 NC punch(25T)

| Production capacity | 60-100pcs/min |

| Applicable Max. size of metal plates | 1000*1000mm |

| Motor power | 6KW |

| Dimension | 2700*2500*2200mm |

| Weight | 2600kg |

NC punch is operated by manual feeding,NC feeding,punch controlled by PLC.

5) 2B3A Edge circling machine

| Applicable can diameter | 50-108mm |

| Motor power | 0.37KW |

| Dimension | 740*1000*590mm |

| Weight | 150kg |

This machine is assembled with automatic or semi-automatic punch for circling edges of round lids,which have been punched shape by the punch machine.

6)GT2C10 Vertical injecting&drying machine

| Production Capacity | 80-110/min |

| Applied lid/cover diameter | 52-153mm |

| Motor power | 1.1KW 380V 50HZ |

| Drying power | 16.5KW |

| Dryer temperature | normal 250℃,doordinate in it |

| Overall dimension | 1800*980*1980mm |

| Weight | 2000kg |

Usage:

The machine applies to inject and dry for coating spray on the tin cap ruling portions for rust proof.

Samples

Jiujiang Gaoxin Metals Packing Mechanism Co., Ltd is one of the leading metal packaging machinery manufacturers in China.The range of machinery made in our company includes cap making machines /production lines( aluminum caps,twist off /lug caps,EOE and other metal caps); can making machines /production line ( round,square and other shaped metal cans) ;NC punching machines;curling & sealing machines for capacitors,filters and other metal containers.Our company has strong technical force and provides to all the customers equipments' matched molds,spare parts,maintenance and technical support all along.

Our company is located in a place with perfect transportation conditions which is only about 2 kilometers to the Jiujiang High-speed railway station, 200 meters to Silver-Fu (Changjiu) freeway, less than one hundred kilometers to the Changbei International Airport.

Welcome to our company for business! We will provide satisfying products and service with good quality and competitive price for you!

1. Warranty: One year after shipment.

2. Delivery Time: 60-90 working days after receiving the advanced payment.

3.Power:3 phase 4 wire, 380V, 50Hz(or according to your requirements)

4. Installation and commissioning

Before installation,we will provide machine layout drawing with dimensions, total power, single power, power interface, water &air input and output position, total water consumption. After the machines arrived and have taken seat,you must connect the water and electric and air into the machines, then we shall send 2-3 technicians to install the production line.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices