- Home

- Categories

- Customized thermoforming plastic embossed blister packaging tray

Customized thermoforming plastic embossed blister packaging tray

- Category: >>>

- Supplier: Shenzhen Bosen Plastic Co. Ltd. [Guangdong China]Shenzhen

Share on (60529971716):

Product Overview

Description

| Product Name | Customized thermoforming plastic embossed blister packaging tray |

| Material Available | ABs,PS,PP,PVC,PET,PET-G,PMMA,PC,HDPE,etc |

| Color | Custom color according to pantone code |

| Material Thickness | The material thickness can start from 0.3mm up to 10mm. |

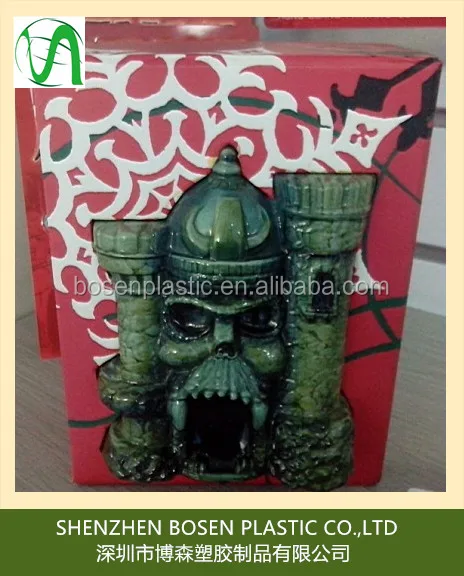

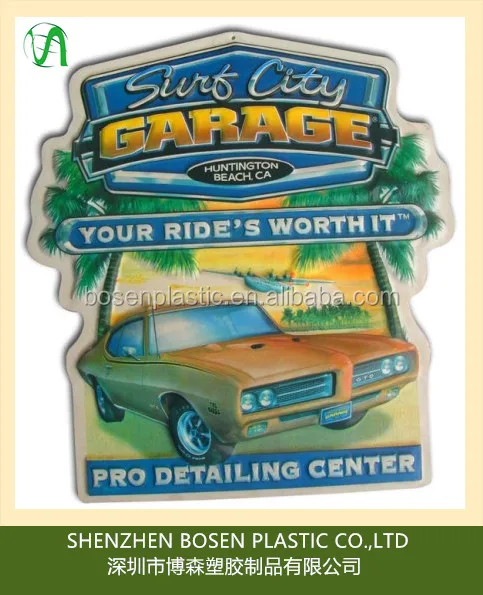

| Surface treatment | The surface can have texture, offset printing, spray painting, screen printing, chrome plating etc. |

| Mould material | Aluminum mold, copper mold, timber mold, plaster mold according to the product design |

| Size | The maximum size can reach 2200x1500 according to customer design |

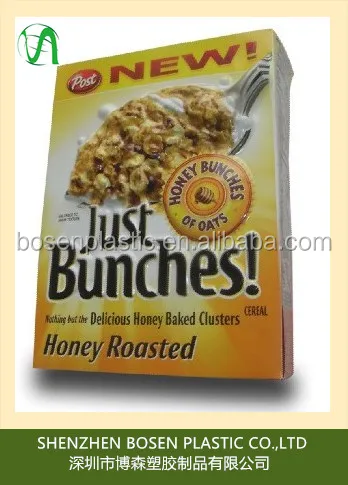

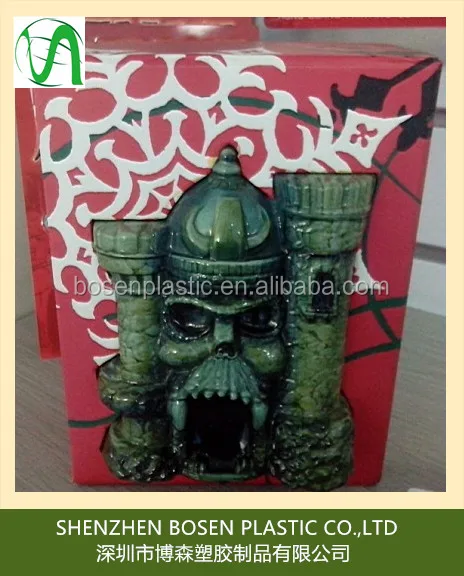

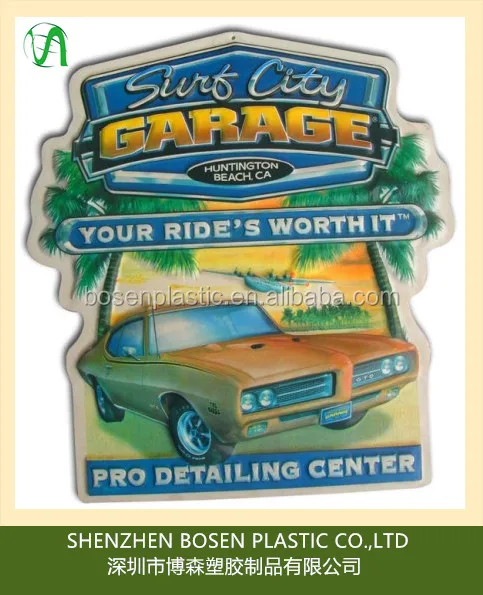

First step-printing on plastic sheet

printing a pre-distorted logo or graphic design onto a plastic sheet, make the mold in aluminum material or copper mold.

Second step: formed on mold

using the vacuum forming process the plastic gets transformed into a new 3D shape and the pre-distorted image miraculously looks normal and perfectly aligned on the plastic creating vivid and engaging graphic affects

Third step: finished product

After vacuum formed to the final shape, take the product off from the mold and trimmed the edges.

What's Distotion printing?

Distortion printing is the process of printing a distorted version of an image onto a sheet of plastic and systematically vacuum forming the sheet on a mold so that specific areas of the printed image appear in corresponding areas of the resulting three-dimensional finished part. At Bosen plastic Co.,Ltd we are experts in the process, which allows us to deliver the quality and detail in our products that is expected in the process of distortion printing to shine through every piece we manufacture. The overall process of distortion printing at BOSEN is performed with control, due to the precise computer software, and with increased speed and repetition. Some key advantages that make distortion printing a top choice in developing are: design innovation which leads to improved branding, higher consumer awareness for our clients, and accuracy in the automated distortion process that helps to eliminate the expenditures associated with previous trial and error procedures.

How to work with us?

Design&Engineer

Tooling&fixture

Our toolmakers have a combined 10 years of experience in tool and fixture making.We take our greatest pride in making quality aluminum tools that deliver consistent quality products year after year.

Factory information

1. Our factory Located in Longgang, Shenzhen, China.

2. Across the company, we have extensive knowledge of the quality and design requirements of the aerospace, medical, and electronics industries

3. Our tooling engineers have over 15 collective years of thermoforming experience.

4. We have 5 of heavy gauge vacuum forming machine, 3 of CNC trimming machine, and 2 of thin gauge thermoforming machine.

5. We take pride in strong working partnerships with our material suppliers and their application development and testing laboratories.

Secondary Services

Bosen Plastic provides a variety of secondary services to our customers so that we can meet all of your end-to-end needs. Our secondary service capabilities include the following:

1. Complex Assembly. Bosen plastic can execute complex product assembly with ease to meet all of your specifications.

2. Painting. Bosen plastic provides in-house finish painting according to your needs.provides in-house finish painting and RF/EMI shielding.

3. Screen printing. Bosen plastic can do the screen printing on the product. The processes can be printing before vacuum forming on flat plastic sheet or after vacuum forming on finished product,we called distortion printed forming.

4. Custom vacuum formed face mask.

5. Plastic vacuum formed display tray with 3d images.

5. Custom vacuum formed shell with graphic printing.

Shenzhen Bosen Plastic Factory have been experts in vacuum forming and all of it's various methods for a decade. We are able to manufacture vacuum formings in any extruded plastic up to 10mm thick, in any colour, up to 2450mm x 1500mm x 600mm in depth.

The advantage of plastic vacuum forming is its flexibility, as are cost effectiveness and speed of production. Prototypes can be produced quickly and accurately to prove parts before full production tooling is required. Tooling costs are also substantially less expensive in comparison to most other plastic process manufacturing, namely injection moulding, especially on large parts or short production runs.

Materials include:

1.ABS (flame retardant, antibacterial and textures)

2.Acrylic capped ABS (for excellent UV and high gloss)

3.Polyethylene and polypropylene (chemical, resistance)

4.Polycarbonate (for high impact)

5.HIPS (for sanitary applications)

6.Speciality materials meeting fire, smoke and toxicity regulations.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A:We are a custom OEM service factory, all the design is according to customer needs, no free sample.

Q: What is your terms of payment ?

We Recommend

New Arrivals

New products from manufacturers at wholesale prices