ESTUN E21 system CNC hydraulic sheet metal press brake, bending machine

- Category: >>>

- Supplier: Maanshan Gilde CNC Machine Tool Co. Ltd.

Share on (60531496769):

Product Overview

Description

ESTUN E21 system CNC hydraulic sheet metal press brake, bending machinene

Front View of Machine:

Video of the machine (watch on PC):

European standard Mold:

ESTUN E21 Controller:

Oil Pump Motor (Siemens):

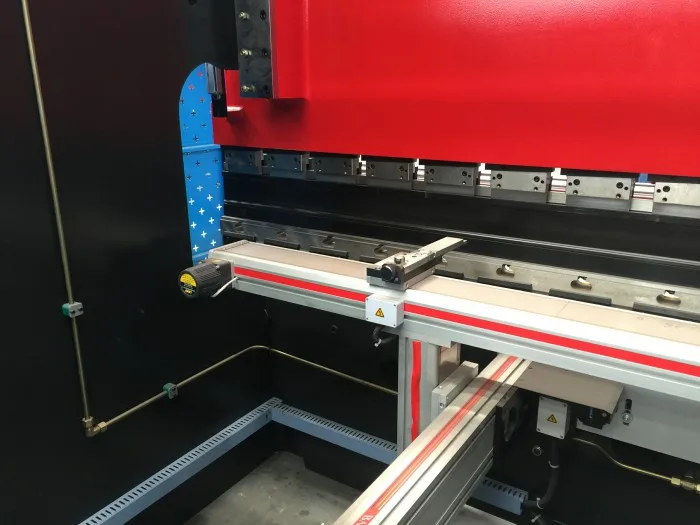

Back gauge:

Electric Cabinet (Schneider electrics):

Valve and Pump (BOSCH, Germany):

Servo Motor:

1.Main Features:

1) Totally EU streamlined design, monoblock by welding robots & apparatus and stress relief process by annealing treatment.

2) WE67K Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum level with its user friendly CNC controller and low cost hydraulic maintenance.

3) Automatic axis referencing and calibrating when machine is turned on.

4) Rigid upper beam runs on 8-point bearings with bending precision of 0.01 mm

5) Well-known top and bottom tool brands are long lasting stiffened and provide precise bending. Silent high pressure pump.

2. Hydraulic system:

1) Hydraulic control system by BOSCH-REXROTH Germany or FIRST America.

2) Oil seals by Japanese, NOK.

3) Overload & overflow protection to ensure there is no leakage and protect hydraulic system,

and the oil level can be read directly.

3.Servo motorized backgauge:

1) CNC backgauge system with X axis by AC servo motor driven ball screw shafts and on linear

bearings with an accuracy of 0.01mm.

2) Backgauge has well enough mechanical strength and rigidity with tank-type gauge structure.

3) High-precision ball screw and linear guide-way. Particular finger-stop design, enlarge the range

of backgauge.

4.Electrical parts and protection device:

1) Schneider or Siemens Low-voltage apparatus. In accordance with international standards,

reliable safety, long life, good anti-interference ability, a radiation unit is fitted in electrical cabinet.

2) Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch, easy to operate.

3) Light screen protection.

5.Delem DA52S CNC press brake control system:

1) 6.4” VGA colour LCD (TFT)

2) Numerical, one page programming

3) Up to 4 axes (Y1, Y2, and 2 auxiliary axes)

4) CNC crowning control

5) USB, peripheral interfacing

6) Servo, frequency inverter and AC control for backgauge axes.

Packaging& Shipping:

Parameter:

Optional CNC System: _________________________________________________

Standard Equipments: __________________________________________________

OUR FACTORY: ____________________________________________________

Established in 2000, Gilde commits to the research and development of sheet metal machinery, pursuing

the best quality and performance. Now we have more than 400 employees and 12 engineers, and the

factory covers an area of more than 70,000 mm2. We can support a wide variety of sheet metal machines,

including press brake, shearing machine, plate rolling machine, press machine and so on.

1.Installation Service

We dispatch technician to customer's factory for installation and preparation of machine operation. ( Customers only need to pay for the air fare and hotel .)

2.Training Service

Our technicians are available to your factory and provide training on how to use the machine. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the air fare and hotel. )

3.Quality Guarantee

We arrange final test before shipment. After making sure machine is in the best condition, we make shipment.

Machine warranty is 3 years.

Our address: Bowang district, Maanshan, Anhui, China

Tel: +86 555 2222129

Whatsapp: 8618055586173

Skype: live:serena_1049

Email: serena(@)gldma.com

It will be a great honour to cooperate with you and we are willing to provide service you need.

Your precious advice and support will be our strongest motivation!

If you are interested in our products, please contact us without hesitation.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices