export to US W11F 3 roll 4mm 1000mm pre bending sheet metal plate rolling bender with profile rolling

- Category: >>>

- Supplier: Maanshan Gilde CNC Machine Tool Co. Ltd.

Share on (60552408366):

Product Overview

Description

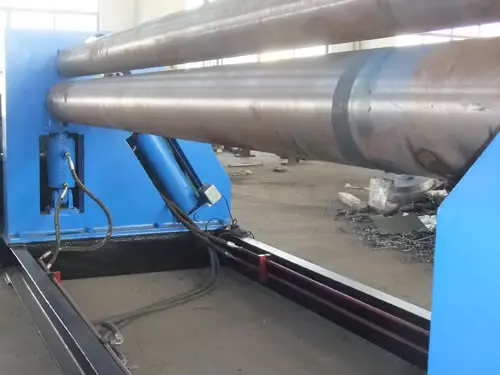

export to US W11F 3-roll 4mm 1000mm pre-bending sheet metal plate rolling bender with profile rolling

Front of the machine:

Main Features:

1,This is a type of 3 roller asymmetric plate rolling machine.The upper roller is the main drive.

|

2,The bottom roller do the elevation movement,through the meshing between the gear of up and bottom roller to clamp the plate tight.

|

3,The side roller do the movement of inclined lifting.

|

4,There’s a double function of pre-bending and circle.It’s impact and easy to operate and maintenance.

|

W11F rolling machine main structure:

|

| 1.The down rollers is the main drive, do the movement of elevation. Through the meshing of the gear between the up and bottom roller to drive the upper roller rotate.The side roller for tilting lifting motion. It’s have double function of pre-bending and circle.Compact structure and easy operation and maintenance.

|

2.The machine consists of two parts, the operation part and the transmission part which are welded at the whole bottom pallet. The operation part consists of left and right bearing housing, one upper roller, one lower roller and one side roller, lifting gears and some accessories. The lower roller is the main one, upper roller can be adjusted at the height. The transmission part consists with the main motor, speed-reducing motor and other accessories

|

3.The lower roller is driven by the main motor through the reducer. The main reductor output shaft transmits to the two lower rollers through a group of gear wheel.Through the meshing with lower roller gear and upper roller gear to drive the upper roller.

|

4.The down rollers’ elevation come from the handle wheel rotate to drive the cam.

|

5.The auxiliary engine drive the worm screw, worm wheel,screw nut,screw mandrel to make the side roller do elevation movement.

|

6.Drop the roller to the appropriate height when unloading.After the machine stopping,take the sliding set from upper roller.

|

Video of the machine:

Parameter:

Detailed Pictures: _____________________________________________________

Control System to Make High Precision and High Speed:

Electrics (from Germany Siemens):

Machining process:

OUR FACTORY:

1.Installation Service

We dispatch technician to customer's factory for installation and preoperation of machines. (Customers only need to pay for the airfare and hotel expense.)

2.Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the airfare and hotel expense.)

3.Quality Guarantee

We arrange a final test before shipment. We will make shipments after making sure machine is in the best performance.

Machine warranty is 3 years.

Our address: Bowang District, Maanshan, Anhui, China

Tel: +86 555 2222129

Whatsapp: 18055586173

Skype: live:serena_1049

Email: serena(@)emagcnc.com

Sincerely invite you to visit our factory and if you have any problems or advice, just contact us. Your suggestion is our treasure and motivation.

Thank you!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices