economic sheet metal JH21 160 tons pneumatic cnc single crank power press machine equipment

- Category: >>>

- Supplier: Maanshan Gilde CNC Machine Tool Co. Ltd.

Share on (60555363908):

Product Overview

Description

economic sheet metal JH21-160 tons pneumatic cnc single crank power press machine equipment

Video of the machine(watch on pc):

1) Machine Structural Feature: |

1. High rigidity:High rigidity,high-precision frame,with welded steel board and heat treated,eliminate inner tension of press. |

| 2. Baliance centre of gravity:The transmission centre is in accodance with the centre of the whole machine,ensure the accurate and stability in pressing. |

| 3. Safe and reliable operation:High-sensitive clutach/braking added international top double electromagnetic valve and overloading protection device,can guarantee the accuracy and safety for sild board running and stopping.The precision of machine adjusting is up to 0.1mm,safer and quick in production adjusting. |

| 4. High-precision:The abrasive sections of crankshaft,gears gearshaft are treated by hardening heat treatment adn followed milling processing ,with high abrasion resistant and balance performance,as well as stable performances.Ensure quality and using life of punch. |

5. Automatiztion processing:Can equip all automatic feeders for automatization production reduce the cost,promote efficiency. |

| 2) Transmission control and brake systems: |

| 1. The Press adopts the low inertia combined dry pneumatic friction clutch and brake from OMPI, Italy, Smoother press performance, easier maintenance, to ensure reliable safety and flexible action,Iow noise, long service life. |

| 2. Driving gear is installed into the frame and gear is immersed in oil reservoir. Customer could choose Electromagnetic governor. which is stepless speed regulation within a certain range and enlarge the area of craf. |

| 3. The press adopts hexahedral rectangle lengthen gib, which has high guiding precision and steady precision. |

| 4. PLC from Omron electrical control system allows various auto-equipment reprogrammed accord-lng to different requirements and perform various functions,to ensure high reliability and high adaptability. |

| 5. Use adopts dual valve from TACO, Japan, which can guarantee the safety and reliability of clutch. |

| 6. Machine is with both hands button and foot switch to achieve continuous, single and inching practices. |

| 7. Auto grease lubrication system,easy stroke adjustment mechanism increases press versatility tremendously. |

| 8. Pneumatic dual balance cylinder, which balances the slide block and punch weight to reduce noise and impact. |

| 9. The press adopts cam controller which be combined with proximity switch (Schneider) which will realize the synchronous detection and monitoring reliably. |

Parameter:

Front view of the machine :

Backview of the machine:

The estun system:

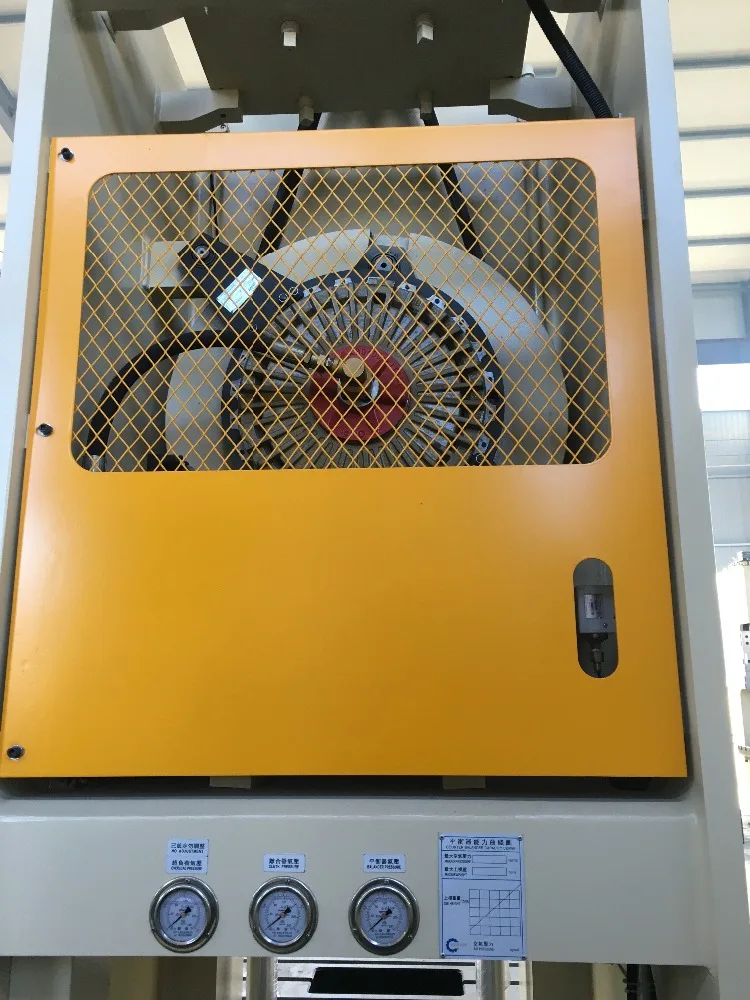

clutch:

The light curtain protection:

The control box:

Package & shipping:

Related:mechanical power press

(⇓click the picture below⇓)

Established in 2000, Gilde commits to the research and development of sheet metal machinery, pursuing the best quality and performance. Now we have more than 400 employees and 12 engineers, and the factory covers an area of more than 70,000 mm2. We can support a wide variety of sheet metal machines, including press brake, shearing machine, plate rolling machine, press machine and so on.

1. Installation Service

We dispatch technician to customer's factory for installation and preoperation of machines. (Customers only need to pay for the airfare and hotel expense.)

2. Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines. ( Customers only need to pay for the airfare and hotel expense.)

3. Quality Guarantee

We arrange a final test before shipment. We will make shipments after making sure machine is in the best performance.

Machine warranty is 3 years.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices