Alloy Carbon Steel Large Vibration Sieve Springs 2mm Length Compression Load Type Coil Flat Chrome Nickel Motorcycles Industries

- Category: >>>

- Supplier: Tianjin Wangxia Spring Co. Ltd.

Share on (60638507053):

Product Overview

Description

metal large Vibration sieve spring damping

Specification :

Product Name | Vibration sieve springs |

Material Option | Steel, carbon steel, Stainless steel, Alloy steel etc. |

Wire Diameter | 0.2mm-90mm |

Customizable | Can made by your drawings, sample and dimension |

Surface Treatment | White zinc plating, Color zinc plating, Nickel plating, Chrome plated, Cataphoresis, Become black, Powder coating, Apply oil ,paint or as customers' request |

Application | Aviation, automotive, motorbike, bicycle, automatic equipment, household appliance, medical device ,toy, telecommunication, computer, instrument and meter, furniture, electric tools, mold and other industries |

Certification | ISO9001 / BV Certificate |

MOQ | 10 pcs, any small trial order is welcome |

Deliver time | 8-10 workdays based on MOQ |

Samples | Some samples can be offered free of charge / Free Sample |

Package | Inner plastic bags and outer cartons or wooden case, Or as per customers' requirements |

Payment term | 30% T/T deposit, 70% before shipping |

Steel Helical Spring Pressure Spring can be used on all kinds of Machinery , Equipment , Industrial , Toys , Chairs , Elevarotr , Clutch , Valve ,Cultivator , Hayrake , Rotary cultivator and some other fields .

metal large Vibration sieve springs damping Showcase and Application :

Please offer the following specification for quotation :

♦ Material

♦ Wire diameter

♦ Surface treatment

♦ Inner diameter and outer diameter(ID and OD)

♦ Free length and work length

♦ Total coils and active coils

♦ Application

Of course, a detailed spring drawing as below is the best.

TIANJIN WANGXIA SPRING CO.,LTD.

Tianjin Wangxia Spring Co., Ltd. is a professional Spring Manufacturer located in Tianjin,China.

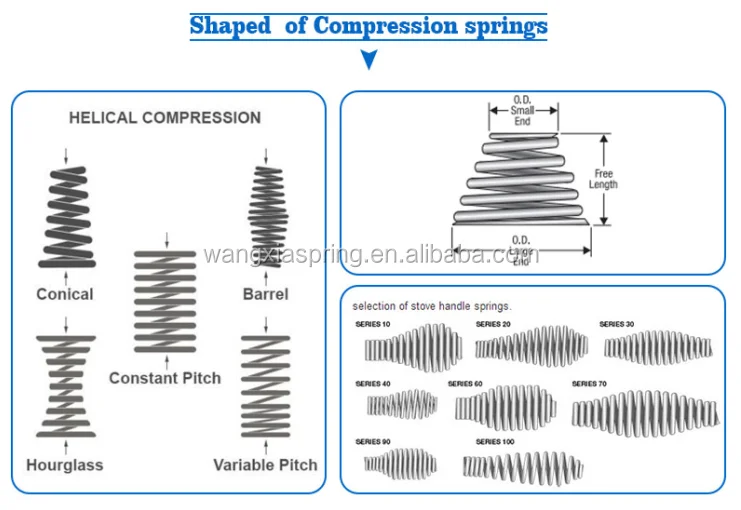

We specialize in producing high-performance Helical Spring Germany Standard, Tension spring, Torsion spring, Garage door Spring , Disc spring, Spiral Spring, and so on.

The company was founded in the year of 2005, the total registered capital of 12 million yuan, is a raw material processing and production of private enterprises spring. The company is located in Jinghai District of Tianjin, covers an area of 15 hectares, the production area of 4500 square meters, more than 60 employees, of which five R & D personnel.

We company has more than 16 automatic spring production equipment, testing equipment 5, a surface coating line, in 2003 passed the ISO9001 product system certification, in 2014 the official product exports, and through the international system BV certification, the products are exported to the United States , Germany, Japan, Canada, Brazil, Algeria, more than 30 countries and regions.

Helical Compression Spring Production Process :

1. Customized design is available OEM ODM are welcome

2. Reply your enquiry in 24 working hours

3. Expericenced staffs will answer all your questions in professional and fluent English

4. Exclusive unique solution can be proof provided by our well-trand and professional engineers

5. Special discount can be offered with large quantity

6. We will try our best to meet your requirements and supply you best quality auto coil spring for suspension system .

Why do business with us?

Here at Tianjin Wangxia Spring Co.,Ltd., we know the importance of getting custom spring orders out quickly, getting them right and keeping prices competitive. Give us a chance to provide you a quote on your custom, heavy duty spring needs. Since 2005, thousands of customers have trusted us with all of their custom compression springs, torsion springs, extension springs, disc spring, mould spring and other special shape springs.

We can get heavy duty spring quotations back to you promptly – offering recommendations on how to reduce costs, improve performance and provide the optimal design for your custom spring needs. To further assist you, we do in-house machining, painting and assembly work.

We’ve dedicated ourselves to being a leader in customer service. So we sweat the details and try to anticipate your needs. We were one of the first custom spring companies on the web, allowing us to communicate better with our customers. One piece orders are no problem for us, and we take pride in our “In a Hurry” deliveries, which help many companies get out of jams and back into production.

Q. Is it possible to obtain a small quantity of a product to check my spring design prior to placing a large production order?

A . In a word, yes, however it’s imperative we both understand exactly what we are attempting to accomplish. All of our products are custom manufactured and often the cost to set up equipment and ensure the quality to produce prototypes is little or no different than set-up costs to run a production order; for example if the prototypes require zinc plating the cost for sub contracting may be exactly the same for 10 pieces as for 2,000. However, if spring load is the only concern of the design, prototypes can be evaluated without being plated. We have equipment and methods specifically geared for prototypes and short run production and regularly produce orders for as few as one or two pieces.

Q. How do I choose the most appropriate spring material for my spring design?

A. • The atmosphere in which the product operates

• The frequency of cycles and the amount of deflection

• The cost of the spring or wireform in relation to the overall project

• The expected life of the product

We Recommend

New Arrivals

New products from manufacturers at wholesale prices