Square Hole power press with feeder for strip cutting Punching Power Press

- Category: >>>

- Supplier: Tengzhou Dingrun Forging Machinery Plant

Share on (60664518419):

Product Overview

Description

Square Hole power press with feeder for strip cutting Punching Power Press

Product Description

Application: ● mechanical Open type press punching machine for blank is suitable for the realization of various cold stamping processes such as

blanking, punching, forming, bending,

and shallow drawing. ● Widely used in electrical appliances, vehicles, tractors, mining machinery, hardware tools, machinery

manufacturing and other industrial fields.

structure

● The mechanical Open type press punching machine for blank manual open type fixed worktable power sheet metal hole punch press

machine has good rigidity and more stable accuracy. ●

The crankshaft is placed vertically, with compact structure and beautiful appearance.

● The manual open type fixed worktable power sheet metal hole punch press machine height of the mold can be adjusted electrically,

and the height can be adjusted by digital display.

● The sliding block adopts a rectangular hexahedral elongated guide rail and a bronze lining board, which has high guiding

accuracy.

● mechanical Open type press punching machine for blank adopts combined pneumatic friction clutch-brake,smooth engagement and

sensitive action.

● Compression type safety device to ensure the safety of the whole machine when it is

overloaded.

● The C type automatic 100 ton power press machine small height of the slider has a lifting balance cylinder to achieve the

balance of the slider connecting rod.

Features

● The manual open type fixed worktable power sheet metal hole punch press machine slider can be moved by inches, and the movement

can be stopped urgently, making the operation safer.

● The road adopts double valve control, which is sensitive in action and meets the safety standards of presses. Product main technical

Application field :

blanking, punching, forming, bending,

and shallow drawing. ● Widely used in electrical appliances, vehicles, tractors, mining machinery, hardware tools, machinery

manufacturing and other industrial fields.

structure

● The mechanical Open type press punching machine for blank manual open type fixed worktable power sheet metal hole punch press

machine has good rigidity and more stable accuracy. ●

The crankshaft is placed vertically, with compact structure and beautiful appearance.

● The manual open type fixed worktable power sheet metal hole punch press machine height of the mold can be adjusted electrically,

and the height can be adjusted by digital display.

● The sliding block adopts a rectangular hexahedral elongated guide rail and a bronze lining board, which has high guiding

accuracy.

● mechanical Open type press punching machine for blank adopts combined pneumatic friction clutch-brake,smooth engagement and

sensitive action.

● Compression type safety device to ensure the safety of the whole machine when it is

overloaded.

● The C type automatic 100 ton power press machine small height of the slider has a lifting balance cylinder to achieve the

balance of the slider connecting rod.

Features

● The manual open type fixed worktable power sheet metal hole punch press machine slider can be moved by inches, and the movement

can be stopped urgently, making the operation safer.

● The road adopts double valve control, which is sensitive in action and meets the safety standards of presses. Product main technical

Application field :

Square Hole power press with feeder for strip cutting Punching Power Press various plastic materials, such as stamping, bending, flanging, sheet stretching, etc. Can also be engaged in calibration, press-fitting, grinding wheel molding, cold extrusion metal parts molding, plastic products,rubber products and powder products compression molding process.

Detailed Images

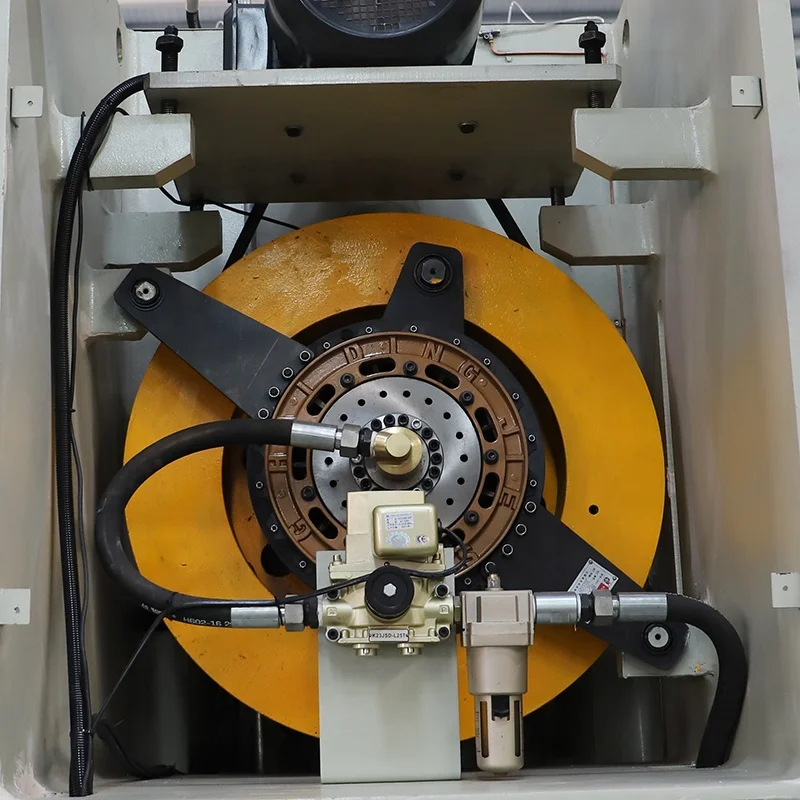

Overload protection

Pneumatic friction clutch

Electrical cabinet

Finished Products

Hydraulic press mainly applies to:

metal non-metallic materials(watches, metal products, bicycles, motorcycles,tableware, kitchen utensils, automobiles, electrical appliances,rubber, grinding wheel, buttons,gold and silver jewelry, ceramics, powder metallurgy, etc.)

metal non-metallic materials(watches, metal products, bicycles, motorcycles,tableware, kitchen utensils, automobiles, electrical appliances,rubber, grinding wheel, buttons,gold and silver jewelry, ceramics, powder metallurgy, etc.)

Related Products

Three beam four column power hydraulic press machine:

Our company has long been committed to the development of forging machinery.We can assure you that our products are of best

quality and reasonable price.

Contact me now.

quality and reasonable price.

Contact me now.

Our Service

Pre-sale service

Process services

The task you entrusted to Dingrun, our professional management team in accordance with the national high standards of quality, do every detail.

Company Introduction

Tengzhou Dingrun Forging Machinery Factory was built in 2005, covering an area of 20,000 square meters, has dozens of production lines, and an annual output value of 150

million. The technical team includes more than 20 engineers, many of whom have been engaged in the forging industry for more than 30 years. With an authoritative technical team to do product management and control, the products we make can withstand the test of the market.

million. The technical team includes more than 20 engineers, many of whom have been engaged in the forging industry for more than 30 years. With an authoritative technical team to do product management and control, the products we make can withstand the test of the market.

Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Packing&Shipping

Conventional four-column hydraulic press under 315 tons in stock packing:

1.The four column metal stamping press machine surface with anti-rust treatment,

2.The four column metal stamping press machine inner layer of plastic waterproof packaging,

3.The four column metal stamping press machine outer layer of thick wood or steel frame fixed,And then use a synthetic board package.

Combined container transport, or separate container transport.

1.The four column metal stamping press machine surface with anti-rust treatment,

2.The four column metal stamping press machine inner layer of plastic waterproof packaging,

3.The four column metal stamping press machine outer layer of thick wood or steel frame fixed,And then use a synthetic board package.

Combined container transport, or separate container transport.

FAQ

Q:What's the price and specification of hydraulic press machine?

A: Dingrun always provide high quality machine, as we know,oversea market is more important and difficult than domestic market because of communication time costing after sales.So always,our machines has enough quality standard to make sure the machine can work more than the real warranty period. In this way ,we will save a lot and think advance for the clients. Please let me know the utensil diameter and height, the pictures and drawing will be better, so that we can check and recommend suitable machine for you.

A: Dingrun always provide high quality machine, as we know,oversea market is more important and difficult than domestic market because of communication time costing after sales.So always,our machines has enough quality standard to make sure the machine can work more than the real warranty period. In this way ,we will save a lot and think advance for the clients. Please let me know the utensil diameter and height, the pictures and drawing will be better, so that we can check and recommend suitable machine for you.

Q:How about your machine quality?We are worry about the quality.

A:Dingrun is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: You can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

Q:May I send samples to test? Do you have a test fee or not?

A: Yes, if you could send us samples, it will be better. For testing, we have to customize the moulds according to your products,so the moulds cost will be on your account, of course the moulds belong to you.

A: You can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

Q:May I send samples to test? Do you have a test fee or not?

A: Yes, if you could send us samples, it will be better. For testing, we have to customize the moulds according to your products,so the moulds cost will be on your account, of course the moulds belong to you.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices