high quality heat insulation environment Polyurethane Sandwich Roof panel

- Category: >>>

- Supplier: Brd New Materials Co. Ltd.

Share on (60681901876):

Product Overview

Description

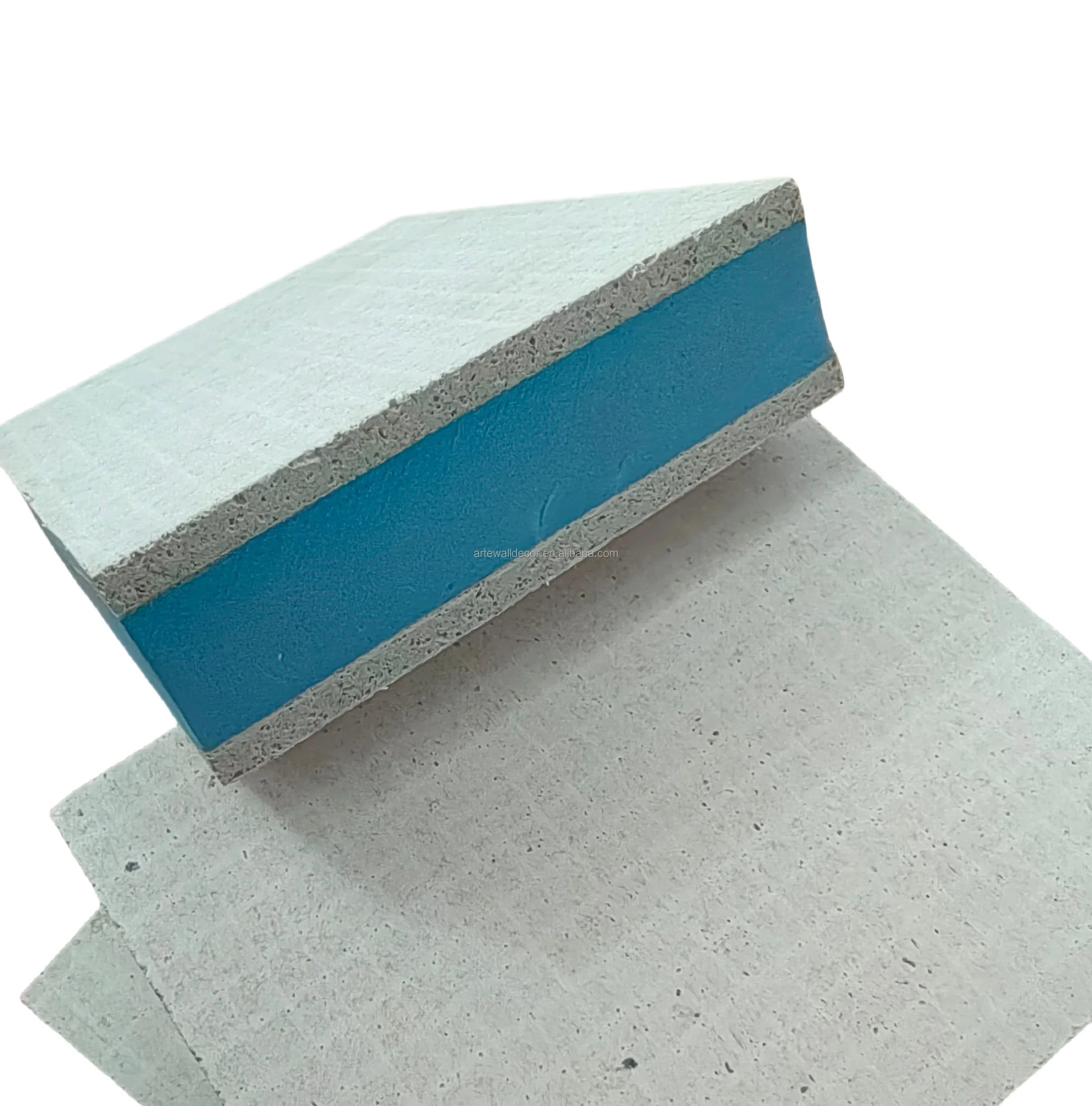

The inner material is the polyurethane foam which has the best effect on heat insulation. It is a new kind of material that frequently used in refrigerating and storing. There are many kinds of styles and dimensions polyurethane foam board. We can meet your demand. The surface steel include color steel, stainless steel and galvanized steel sheet. You can choose freely. The metal panel and the inner material are molded and bonded at one time.

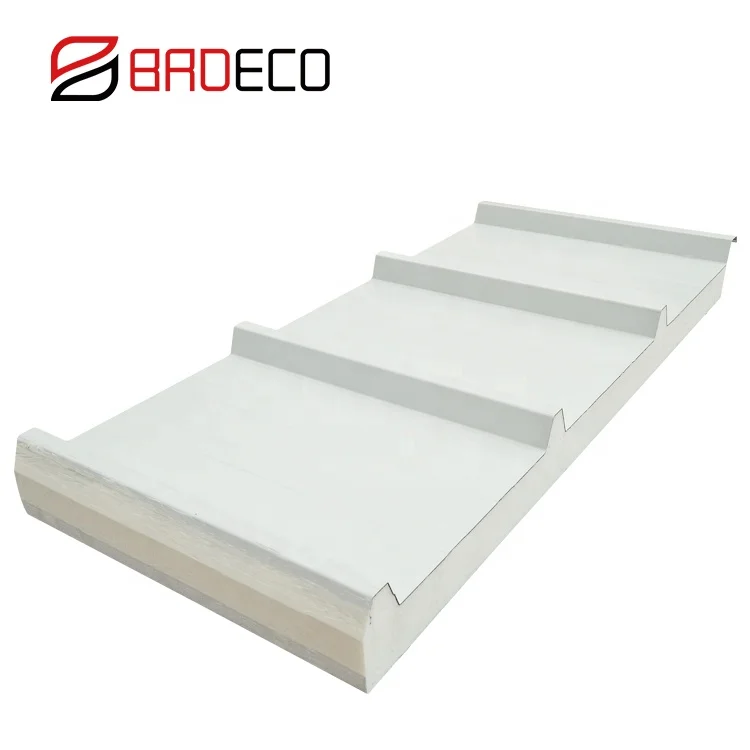

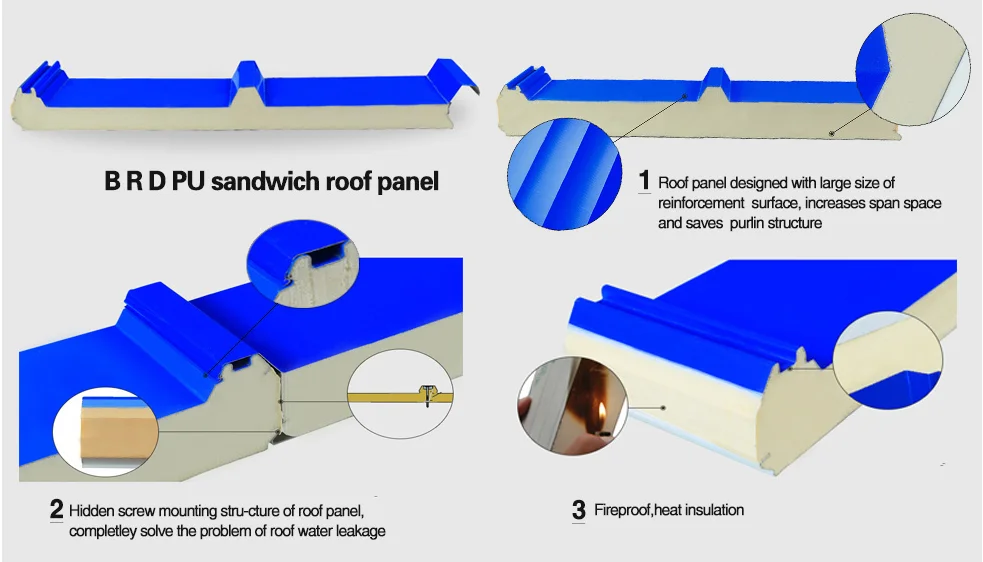

As a new material, the polyurethane roof panel has been the most suitable choice for many users. The polyurethane roof panel is divided into two types: the three waves of polyurethane sandwich roof panel, the four waves of polyurethane sandwich roof panel. The characters of pu roof panel are heat insulation, waterproof, soundproof, and easy to install. The excellent function is the reason that so many people choice it as roof board.

1.Created exclusively 4 wave roof panel in China for the first time, more powerful for snow load.

2.Exclusively adopt the 3 wave roof, embedded installation, dark nail waterproof technology, easy installation, guarantee 100% hold water.

3.Adopt the 40 cm peaks, increase the surface strength, easy drainage, reducing both snow load and wind load by 170%.

4.Super flame retardation

The coefficient of thermal conductivity is 0.023w/(m•k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

5.Easy and quick installation

Compared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

It can be used in large industrial plants,warehouses supermarkets, hospitals, stadiums, cold storage, activities room, buildings plus layer, clean workshop and heat insulation fire place.

1, First of all, it must carry on the construction preparation before installation, include personnel, materials, etc. All will be well prepared.

2, Before the installation of polyurethane roof panel, it should check whether the verticality and levelness of metope purlin installation requirements, wall frame column vertical degree meets the requirement.

3, Polyurethane roof panel links with ground.

Lateral links: fixed polyurethane sandwich panel with the ground at the other end of the round hole with steel frame fixed, connection between the two plate mouth involution, if occurrence crack of the connectors available heat preservation to fill.

Vertical links: the gap between plates, using the dedicated button concave groove in the fixed polyurethane roof panel.

BRD is a strong productivity. We introduced several Italian totally automatic production lines and adopted Chinese Total Productive Management System. The annual output includes 1.2 million meters of polyurethane sandwich panel, and 10 million tons of steel structure. We take part in many famous exhibitions, like Canton Fair, Thailand ASEAN International Exhibition, and so on. We sincerely hope to cooperate with you to create a double win situation.

Our product’s distribution covers more than 21 provinces and cities in China. Meanwhile, BRD Group was exported to a lot of foreign countries, sales net has covered over 21 countries and places, such as Russia, Brazil, Peru, Trinidad and Tobago, Australia, Sweden, and some other countries in Southeast Asia ,South Africa and other places.

BRD Group, was established in 1995, which is a listed company in Middle China. It is one of the earliest building materials manufacturers.There are more than 30 million square meters production area, more than 500 existing staffs. BRD Group is committed to make the buildings more green, more environmentally friendly and energy saving.

Large Scale Workshop

BRD GROUP is located in Changge Industrial Zoon, Xuchang city, Henan province.Also have two branch workshops located in Zhengzhou and Qingdao city. The three cactories enjoy 100,000 square meters. 7 automatic production line to produce on time, the garage door machine can make 100 sets per day.

![(%4}4DO22A_S]5B5D{W9K95](http://sc02.alicdn.com/kf/HTB1iK3HPVXXXXX6XVXX760XFXXXL/230302361/HTB1iK3HPVXXXXX6XVXX760XFXXXL.png)

Advanced Machine

Automatic production line, which is the longest in China, to ensure the quality and quantity.

Our team continues to improve the standards themselves, and we have to build a first-class quality, first-class benefits, first-class modern enterprise management as the goal, We are committed to the development of new energy-saving products, with independent intellectual property patents production technology, the introduction of German technology imported main material adhering to the "committed to being respected and have capacity for sustainable development of enterprises" for enterprise vision. Adhere to the "promotion of industrial innovation and circulation of the intensive use of social resources" for enterprise mission, continuous innovation, promote the building decoration industry to a green, low carbon, health, environmental protection, energy saving direction.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices