Professional Street Light Pole Making Machine

- Category: >>>

- Supplier: Jinan JinPin Roller Mould Co. Ltd.

Share on (60688159461):

Product Overview

Description

Equipment compenent:

1.ZDW43J-6*1800 cut to length line.

2.ZQ11-6*2400*14000 steel plates diagonally shearing production line.

3.2-WE67Y-200/7000 tandem press brake(for the street poles)

4.HFH320*5-14000 automatic welding production line

5.MZ630SS-14000 semi-automatic welding production line.

6.HF500*8-14000 mechanical seam machine

7.W31Y-600*10 steel straightened machine.

8.WG90*4 tube bending machine.

9.ZDMJ-350*14000 automatic grinding machine

10.ZJP-14000 electrostatic spraying prodcution line

The above equipment can order according to your euqipment and producing.don’t buy cause waste.please consult to us if you don’t understand.we can be your best staff officer with sincere heart.insure of your mistake buying.we will do our best to let your make the best use.

Processing flow:

1. coil feeding 2. coil processing 3. steel plates diagonally shear to trapezoidal type 4.bending materials transfer 5. plates bending on press brake 6.transfer poles with seam to submerged arc welding production line 7. straighten steel poles 8.welding flanges and door lights 9.bending poles until forming 10. transfer galvanized 11.spraying (according to the request) 12. install the lights 13. delivery and installation

The area of workshop:it need about 60000*18000mm two to three rooms,without stacking area and welding area.we can design the plant according to the users actual sizes ,ensure the operating production line.it need the power with about 100 kilowatt.

Quality and services

1.The course of designing, producing and selling are performed according to iso 9001.

2.Our company can suplly study , installation and provide parts and repairing service all of the life.

3.Free training and take charge of the adjusting.

4.When equipment arrived, do well of the after service on time,reply in 6 hours and arrive to user ends in three work days.

Products Specification:

Height | 3 meter to 30 meter |

Suit for | Airport, seaport, roadway, etc |

Shape | Conical or octagonal or Polygonal |

Material | Normally Q345B/A572, Minimum Yield Strength ≥ 345 N/mm² Q235B/A36, Minimum Yield Strength ≥ 235 N/mm² As well as Hot rolled coil from ASTM A572 GR65, GR50, SS400 |

Tolerance of the dimension | <2% or as requirement. |

Surface treatment | Hot dip galvanized Following ASTM A 123, or any other standard by client required. |

Joint of Poles | Slip joint, flanged connected |

Standard | ISO 9001:2008 |

Length of per section | Within 14 meter once forming |

Welding Standard | B/T13912-92 standard. |

Thickness | 1 mm to 36mm |

Production Process | Raw material test → Cutting →bending →Welding (longitudinal )→Dimension verify →Flange welding →Hole drilling →sample assemble → surface clean→ Galvanization or powder coating ,painting →Recalibration →Packages |

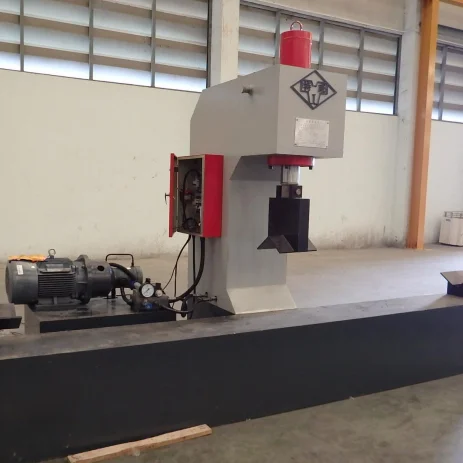

Product's photo:

Production process:

Design –Material Testing –Cutting-Bending –Welding-Cleaning-Hot Dip Galvanizing-Straighten-Quality Testing- Packing- Delivery-Installation- Lighting

We Recommend

New Arrivals

New products from manufacturers at wholesale prices