- Home

- Categories

- Four station gallon water filling line/plant/device with overflow valve

Four station gallon water filling line/plant/device with overflow valve

- Category: >>>

- Supplier: Zhangjiagang City Fillpack Machinery Co. Ltd.

Share on (60734053668):

Product Overview

Description

| Four station gallon water filling line/plant/device with overflow valve | ||

| Items | Name of machine | Model |

| 1.1 | Automatic De-capper | CR-1 |

| 1.2 | Brush Internal-External Bottle Washer | WS-1 |

| 1.3 | Washer/Filler/Capper with auto bottle loading | WFC-600BPH |

| 1.4 | Heat Shrinking Machine | ZSM-1 |

| 1.5 | Checking Light | CL-1 |

| 1.6 | Conveyor Belt with Motor | / |

1.1, Automatic De-capper

This gallon water filling line is driven by cylinder, controlled by PLC; Automatic working by barrel checking;

De-capping head is composed by claw device and cylinder, de-capping head position can move up and down, claw device can be adjusted slightly to be suitable for different caps.

When the gallon bottle comes into the machine, the de-capping head will go down and claw device will hold tightly barrel cap sides, and then lift the barrel to take off the caps; And when the caps are taken off, the compressor air will blow the caps into cap hopper, then fall outside into client’s own holder;

The claw pressure is adjusted to protect caps;

| Parameters | |

| Dimension | 650*800*1600mm |

| Weight | 100kg |

1.2, Brush Internal-External Bottle Washer

The gallon water filling line is completely blocked to stop water leakage, when the gallon bottles are sent to washing position, the cylinder will increase the inner washers and insert into bottles, when the bottles are fixed by all brushes, the water will be pumped and jetted to bottle body, bottle rotates together with brushes; The bottles will be cleaned by brushes and water function;

No air compressor needed, it is easy for production and maintenance;

| Parameters | |

| Brush qty | 4pcs*2 |

| Dimension | 2000*1200*1750mm |

| Weight | 800kg |

| Power | pump 0.37+motors 0.75*2=1.87KW |

| Recycle water tank size | 600*550*550mm |

| Components | |

| PLC | Mitsubishi |

| Cylinder | AIRTAC |

| Air switch-Contactor-Relay | Schneider |

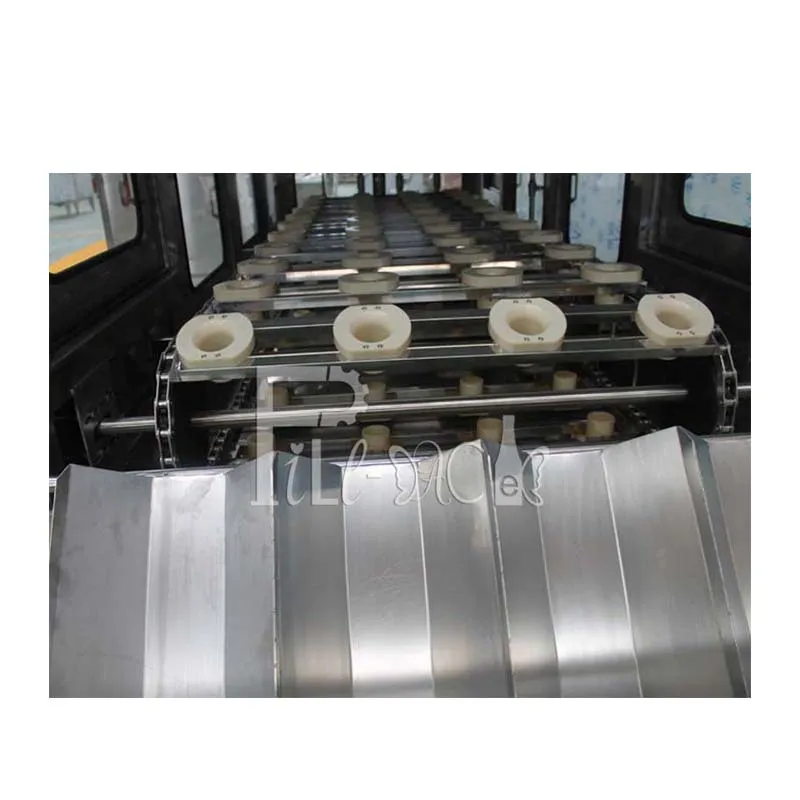

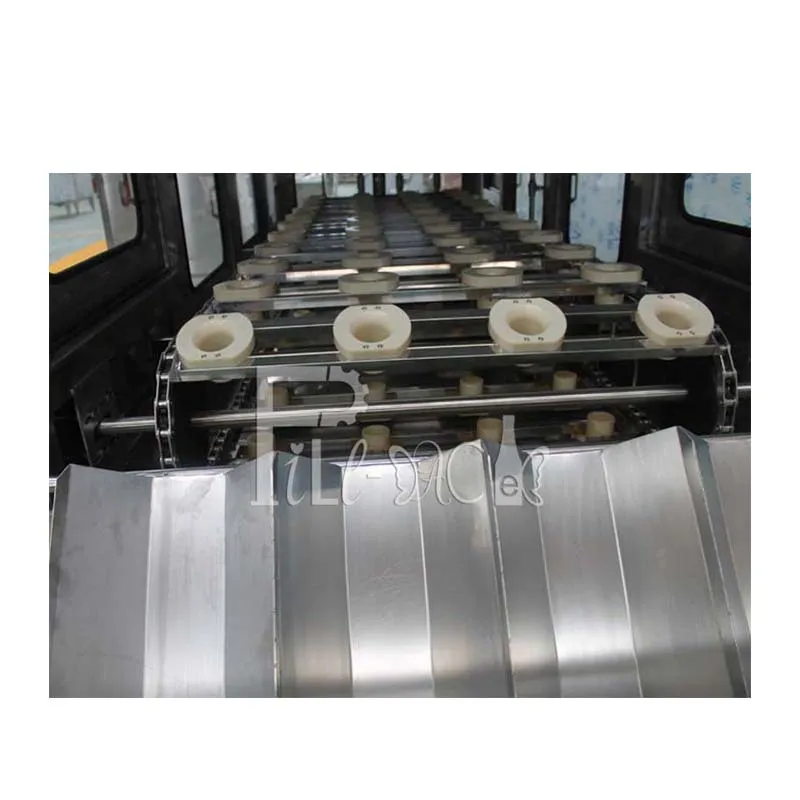

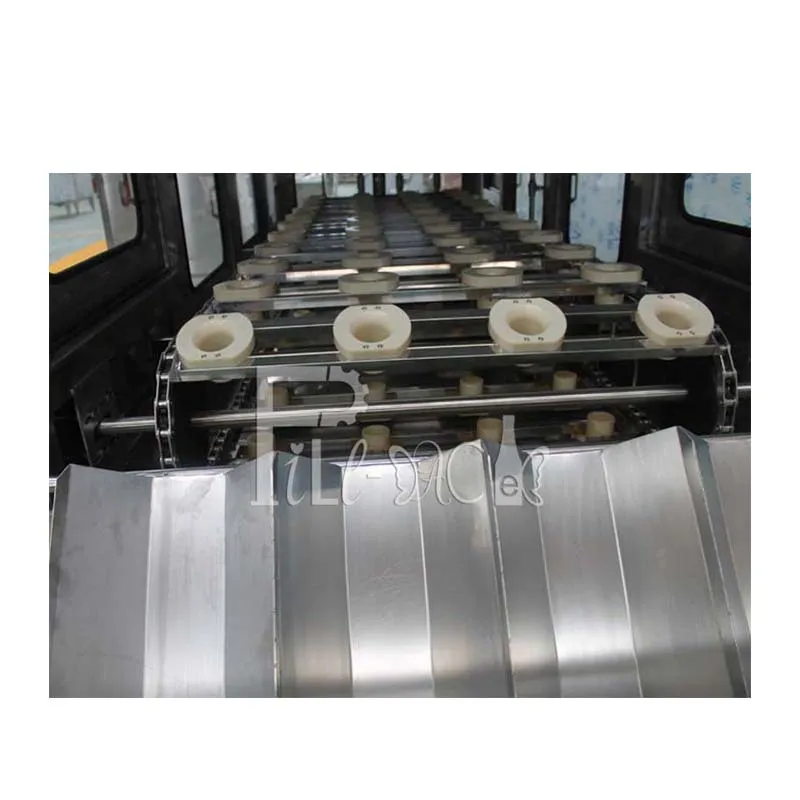

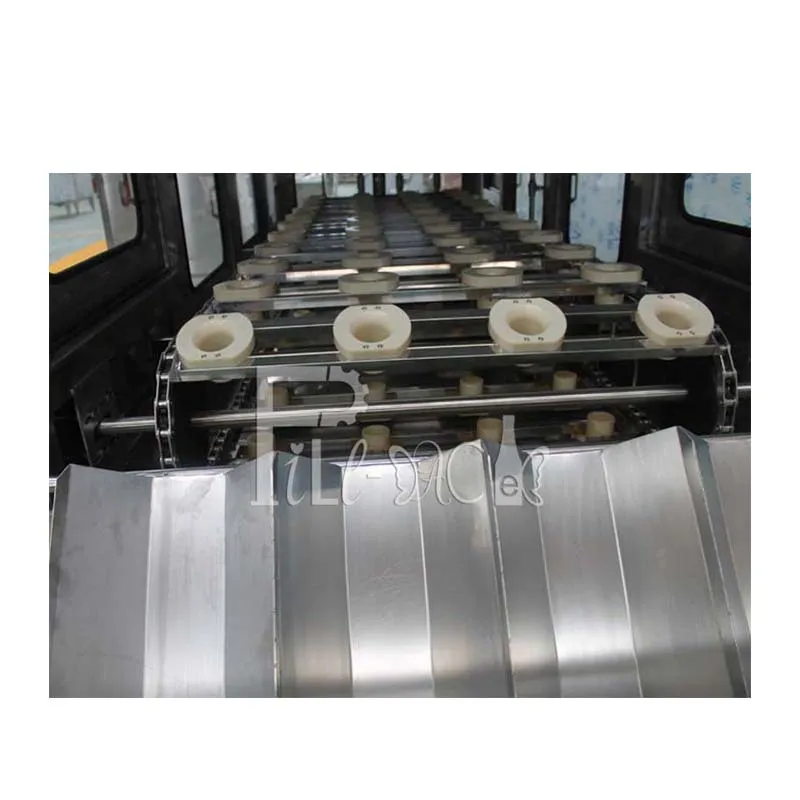

1.3, Washer/Filler/Capper with auto bottle loading

gallon water filling line is integrated washing filling and capping together. It is ideal machine to produce barrel water. The whole machine is using stainless steel 304 ,rot resistant,can be cleaned easily。Main electric parts are all branded. Air channel system use Air TAC brand product。The machine is with compact construction,will occupy small room,working efficiency is high。Only need 2 operators to control, is a good choice for factory to choose.

The gallon water filling line set up do not need plug floor screw,after case taking off,set the machine on the flat floor,and then adjust stand height and adjust all stand pressure to be average. After the machine is set up well, get in through water pipe, drain pipe and power , air power.

Working process:

gallon water filling line can be divided into 3 steps: washing, filling and capping, total 36 working stations,working process as below:

(1)Set empty barrel mouth to barrel seat, empty barrel will be washed during headstand situation,4 working station for barrel inserting.

(2)Washing process will be divided into 4 steps:1, hot alkali water washing 2,thimerosal washing;3,clean water washing,4,pure water washing.Every washing step is set to 8S,after washing,there will be 10S for dripping.

(3)The barrel after washing will move down 45 degree through the passing chain and will passing out chain and turn over 45 degree by barrel lift cylinder to filling position for filling.

(4)Filling value will driven by cylinder to insert into barrel and start to fill, filling time is controlled by PLC, and filling time is adjustable by control panel according to filling liquid surface.After filling, the extra water will back to pure water tank by automatic vent,it can reduce water consumption.(water tank is not included)

(5)After filling process finish,the filled barrel will be pushed to capping position by barrel stop cylinder,the whole process finish till now.

| Parameters | |

| Cylinder | Air tech-Taiwan |

| Magnetic valve | Air tech-Taiwan |

| Rising pump-filling pump | Nanfang |

| PLC | Mitsubishi Japanse |

| Power | 1.5KW |

| Dimension | 6000*1800*1800mm |

| Weight | 1000kg |

1.4, Heat Shrinking Machine

Whole SUS304 construction, Including electrical boiler to generate steam and shrink tunnel specially for barrel cap film;

Power: 20KW

Dimension: 800*600*1200mm

Weight: 100kg

1.5, Checking light

Power: 0.09KW

Dimension: 1000*100*450MM

Weight: 10kg

Conveyor

1. the gallon water filling line is packed by wooden case.

2. The delivery date of gallon water filling line is within 30 days after payment.

1.installation&commissioning

After the equipment arrived at the customer's site. the customer is responsible for unpacking and arranging the equipment according to the placement drawing;Our technician will do equipment set up and commissioning,buyer should offer necessary help if needed

2.Training

We are responsible for offering the technical training to user.Through training,users' technical staff can grasp and the skill of operation and maintenance proficiently.The buyer also can send staff to our company for learning.

3.Quality assurance

The warranty period is 12 months after acceptance chech of the production line.if there is any different between the furnished equipment in the customer's factory and the equipment concerned in the contract.

1.Why do you choose our factory?

There are many foreign guests cooperate with our company.We have enough experience and fund to provide you the high-quality products with the best price.

2.How long can you delivery?

About 30 days after we received the deposit(30%T/T in advance,70%T/T before shipment.)

3.How about your after-sale service?

One year repair for free Seller responsible for arrange engineer for installation and guide the workers of buyer how to operate and necessary repair,and give buyer a turnkey project.

4.How long can you finished the installation?

About 10-15 days.If the water and electricity is ready.If you have any questions,please do not hasitate to contact me.

ZhangJiaGang City FILL-PACK Machinery Co.,Ltd. is loacated in Zhangjiagang city which is famous for beverage machinery producer collection. Intergrated the industry advantange and its own development in R&D, production, sales, after sales service, FILL-PACK is ready to serve more and more customers with our full range products and satified service.

FILL-PACK product is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

At present we produce: production lines for mineral water, pure water, fruit juice, tea drink, milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 80-1200 barrels per hour and various water treatment plants; We provide separate machinery or turnkey project.

Our product pass quality inspection executed by Bureau of Quality and Technical Supervision every year. Our factory is in accordance with ISO9001: 2000 certification system standards and we gain CE certificate for exportation to Euro countries. Our machineries are sold to more than 30 cities in China and over cross to American, Spanish, Hungary, middle east and African countries.

As shown from picture, we gave depth customizations to our customers. we could design drawings for the factory to produce ideal drinking which are our customers really want. No matter which type of customers, new starters or Industry leaders, personal or purchasers, we can provide Intimate service. Our machines are sold to cities in China and over cross to Europe, American countries, Africa, Oceania, Middle east and Asian countries. We sincerely hope to cooperate with you for a bright future!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices