- Home

- Categories

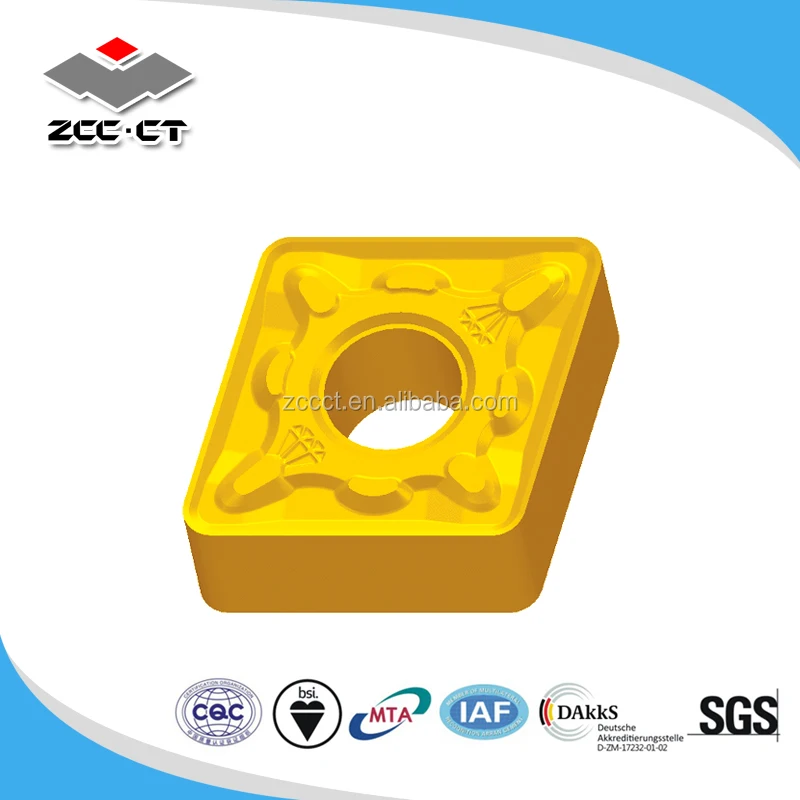

- CNC turning insert CNMG12 for steel machining

CNC turning insert CNMG12 for steel machining

- Category: >>>

- Supplier: Zhuzhou Cemented Carbide Cutting Tools Co. Ltd.

Share on (60737303618):

Product Overview

Description

CNMG120408-DM/YBC252: CNC turning insert CNMG12 for steel machining

DM: Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability.

YBC252: CVD coated P20–P35 carbide grade for medium operation to roughing of steel and casting steel. Optimal performance of wear resistance and toughness for a wide application field.

Details:

DM: Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability.

YBC252: CVD coated P20–P35 carbide grade for medium operation to roughing of steel and casting steel. Optimal performance of wear resistance and toughness for a wide application field.

| Type | Grade | L | φIC | S | φd | r |

| CNMG120408-DM | YBC252 | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

Notes:

1. This is ZCCCT official flagship store on Alibaba website. All products are delivered directly from ZCCCT warehouse.

2. Samples are free, but you need to pay the delivery fee to DHL.

3. More than 50,000 items are valid. Please contact us to get the full vision catalogue.

ZCCCT has plenty of chip breakers to choose which cover the application range from steel, iron cast, stainless steel, aluminum, heat resistant alloy, etc. Those chip breakers can replace the relative ones of SANDVIK, KORLOY, TAEGUTEC, MITSUBISHI, SUMITOMO, TUNGALOY, KROCERA, DIJET, ISCAR etc. DON'T HESITATE TO CONTACT SUPPLER TO GET MORE DETAILS!

| NO | Chip Breaker | Introduction | Competitor (Chip Breaker) |

| 1 | PM | Double sided chip breaker for medium machining. Wide range of application in steel and cast iron. | SANDVIK(PM) |

| 2 | DF | Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. | SANDVIK(-PF), SECO(-MF1) |

| 3 | DM | Double sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. | SANDVIK(PM), SECO(MF2), KYOCERA(HQ) |

| 4 | DR | Double sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. | SANDVIK (PR,QR) |

| 5 | EF | Double sided chip breaker with good chip control. Suitable for finishing and medium machining of steel and cast iron. | KYOCERA(-CF) |

| 6 | EM | Double sided chip breaker with sharp cutting edge and large rake angle. Process reliable medium machining of stainless steel. | TUNGALOY(TM) |

| 7 | ER | Double sided chip breaker with large rake angle for low cutting forces. Suitable for roughing of stainless steel. | SANDVIK (MR,QR) |

| 8 | LH | Single sided chipbreaker for machining of cast aluminium alloys. Sharp cutting edge with positive rake angle. G-tolerance for high repeatability. | KORLOY(AR) |

| 9 | LC | Single sided chip breaker with excellent cutting edge design. Sharp cutting edge with positive rake angle. G-tolerance for | KORLOY(AK) |

| 10 | HF | Single sided chip breaker with good chip control. Suitable for finishing to medium machining of steel and cast iron. | MITSUBISHI (FJ,FV), KYOCERA(CF) |

| 11 | HM | Single sided chip breaker for medium machining. Wide range of application due to excellent balance of sharpness and cutting edge stability. | MITSUBISHI (FJ,FV), KYOCERA(CF) |

| 12 | HR | Single sided chip breaker with positive rake angle and stable cutting edge for light to medium roughing of steel and cast iron. | SANDVIK (MR,QR,PR) |

| 13 | TC | Double sided chip breaker with surrounding cutting edge. Process reliable machining due to highest cutting edge stability. | MITSUBISHI (GH) |

| ... | ... | DON'T HESITATE TO CONTACT US TO GET MORE DETAILS! | ... |

ZCCCT products range covers indexable inserts with PVD, CVD coating grade, ceramic and extra-hard material grade. YBC series, YBD series and YBM series are our “BLACK DIAMOND INSERTS” which have a very good reputation in the markets. YB9320 is our new generation of PVD coating, which improves tool life more than 20%. DON'T HESITATE TO CONTACT US TO GET MORE DETAILS!

| No. | Grade | Grade description | Grade(Competitors) |

| 1 | YBC152 | CVD coated P10–P20 carbide grade for finishing to medium operation of steel and casting steel. Outstanding performance under higher cutting speed and temperature with excellent wear resistance. | GC4315(SANDVIK), E6020(MITSUBISHI), T9125(TUNGALOY) |

| 2 | YB6315 | CVD coating grade combining nano dioxygen gradient transition techniques and crystal nucleus pre-insertion techniques. | GC4315(SANDVIK), T9115(TUNGALOY) |

| 3 | YBC252 | CVD coated P20–P35 carbide grade for medium operation to roughing of steel and casting steel. Optimal performance of wear resistance and toughness for a wide application field. | GC4325(SANDVIK),E6020(MITSUBISHI),T9125(TUNGALOY) |

| 4 | YBD102 | CVD coated K05–K20 carbide substrate. Optimized for medium operation of cast iron, special nodular cast iron and hard steel at high cutting speed. | UC5115(MITSUBISHI) |

| 5 | YBD152 | CVD coated K10–K25 carbide substrate. Optimized for medium to roughing operation of cast iron. Good wear resistance and toughness at higher cutting speed. | UC5115(MITSUBISHI) |

| 6 | YBD152C | Thick Al2O3 CVD coated K05–K25 carbide substrate. Optimized for medium to roughing operation of cast iron.Higher wear resistance and toughness at higher cutting speed in combination with TC chip breaker. | UC5115(MITSUBISHI) |

| 7 | YB7315 | CVD coated K10–K25 carbide substrate. Optimized for medium to roughing operation of cast iron. Improved wear resistance and toughness at high cutting speed. | UC5115(MITSUBISHI), WAK20(WALTER) |

| 8 | YBM153 | CVD coated M10–M25 carbide grade for fnishing to medium application in stainless steel. High wear resistance and capability against plasctic deformation at higher cutting speed. | |

| 9 | YBM253 | CVD coated M15–M35 carbide grade for medium to roughing operation in stainless steel with wide application field. High wear resistance and capability against plasctic deformation at higher cutting speed. | |

| 10 | YBG202 | PVD coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel and steel (milling). Good wear resistance in a wide application field. | |

| 11 | YBG205 | PVD multilayer coated M20–M40/S15–S25/P10–P30 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (milling). Good wear resistance and thermal stability in a wide application field. | VP15TF(MITSUBISHI) |

| 12 | YB9320 | PVD multilayer coated M10–M25/P10–P30 carbide substrate for finishing to medium application of stainless steel, super alloy and steel (grooving/milling).Optimized coating stability for higher wear resistance and thermal stability in a wide application field. | |

| 13 | YNT251 | Uncoated P10–P25 cermet grade for fine finishing to medium operation of steel and stainless steel. Good wear resistance and toughness. Suitable also in light interrupted cut. | |

| ... | ... | DON'T HESITATE TO CONTACT US TO GET MORE DETAILS! | ... |

ZCC•CT has a complete range of products. We are capable of providing both standard and tailor-made products.The products range covers indexable inserts with PVD, CVD coating grade, ceramic, extra-hard material grade,and solid carbide cutting tools and tool system with high precision.ZCC•CT products can be applied in turning, parting, grooving, threading, milling, drilling and boring.

If you haven't found your products, please contact me to get our full catalogue. More than 50,000 items to choose!

ZCCCT is China’s leading supplier of cemented carbide cutting tools, including production, R&D and marketing. It is a key enterprise of China Minmetals Corporation, Fortune Global 500,which owns 21% of China's tungsten resources and 34% of China's Cemented Carbide output. ZCCCT has more than 1800 employees worldwide and is setting up wholly owned subsidiaries in the United States, Germany and France. We build world-class production lines of indexable inserts, ceramic inserts, tool holders, solid carbide end mills and drilling tools.

If you dedicate to metal working and want to become our official distributor in your country, please contact us. ZCCCT continuously improve sales and marketing network. A worldwide sales network has been established through our oversea subsidiaries, agents and distributors.We demonstrate our advanced manufacturing level to customers through exhibitions and holding activities such as open day for customers and summit forum, etc.

Q1: Why are there so many cheap zccct products in the markets?

A: Even in china, we are fighting against fake products every day. The risk of getting in trouble is very high if those products are not come from official channel.

Q2: How does zccct guarantee the quality?

A: Our products are 100% inspected and we have established strict, systemic test standards. We are qualified to state key laboratory of cemented carbide by ministry of science and technology of P.R. china.

Q3: Do you provide samples? Are they free?

A: Yes, we provide insert samples and they are free when the insert quantity is less than 5 pieces, but you need to pay the delivery charge to DHL. We also offer you complimentary milling cutter bodies if you purchase milling inserts up to a certain amount.

[RETURN HOME PAGE]

We Recommend

New Arrivals

New products from manufacturers at wholesale prices