Automatic toilet cleaner anti corrosive disinfection liquid bleach vinegar acid filling machine

- Category: >>>

- Supplier: Mic Machinery Technology Co. Ltd.

Share on (60743518568):

Product Overview

Description

This machine combines optical, mechanical, electrical, gas in one machine. Adopt through control filling time to reach different volume filling. Filling time can be precisely controlled to a hundredth of a second. The filling process is completed under the PLC program control on the touch screen. Having a stable and reliable operation, high efficiency, adaptability, the filling volume of measurement specification can be changed within a few minutes. Filling valve use imported brands, advanced technology, sophisticated, non-drip filling phenomenon.

Weight | 1200KG |

Power | Customized |

Filling Volume | 500-5000ml |

Filling Error | ≤3% |

Suitable Filling Material | bleach, pesticide, sulfuric acid products |

Suitable Barrel Width | 120-250mm |

Air Consumption | 0.6m³/min |

Dimension | 2000*1300*2200mm |

Power | 2.2Kw |

Filling Nozzle | 12 nozzles |

Capacity | ≤3500BPH |

Suitable Barrel Length | 180-330mm |

Suitable Barrel Height | 80-450mm |

Working Pressure | 0.6Mpa-0.8Mpa |

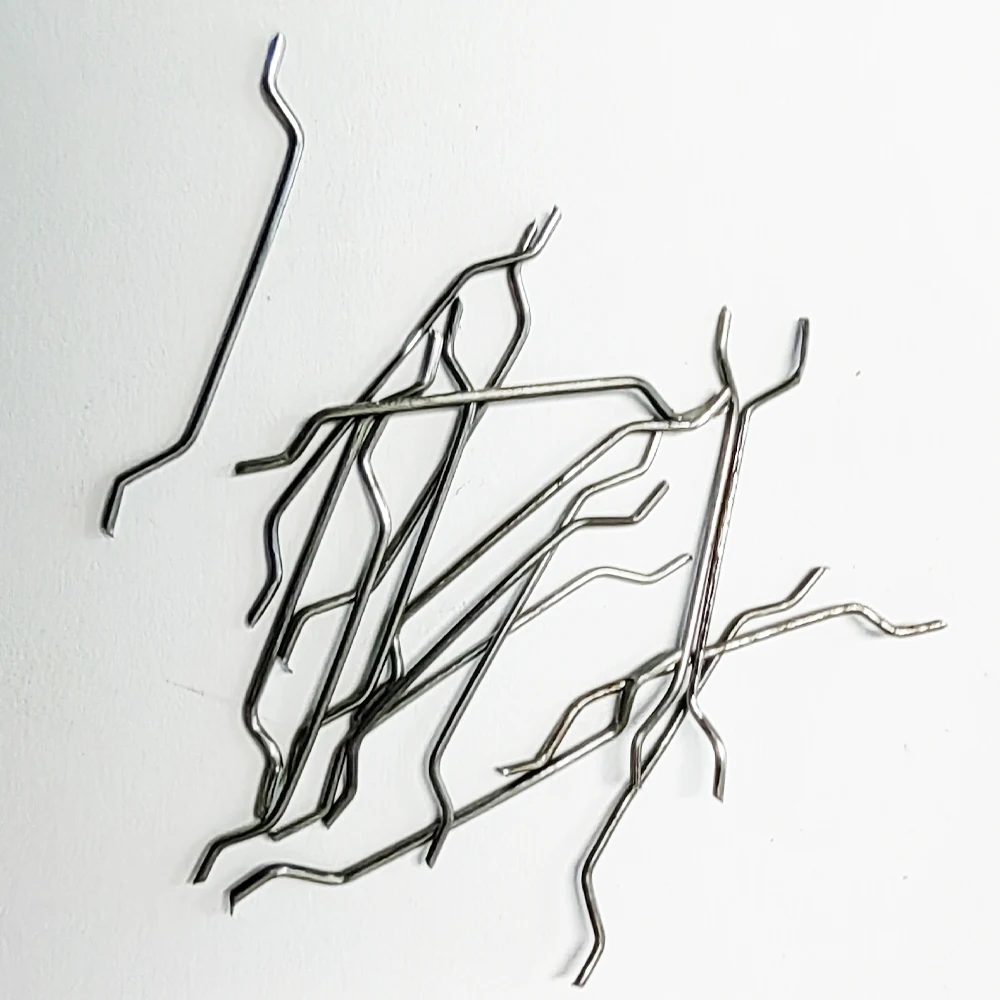

Filling Heads

Every filling head has anti-drop design. It promise do not waste the material. And diameter of filling head basis on the diameter of customer’s barrel’s mouth. The tube material is PTFE, corrosion resistance. The filling heads are also PTFE material. They will go down into the bottles when start to fill.

Material tank and Valves

The valves are also used to control the bleach filling time and anti-corrosion. The material tank is made of PTFE material, corrosion resistance. The material tank uses the slope design, it is more easy for the customer to change the material, meet GMP requirements

Time control filling valve

This valve is controlled by PLC system, and it use time control to set the filling volume. The filling volume settings can be done on the touch screen

We Recommend

New Arrivals

New products from manufacturers at wholesale prices