XSG Model Calcium Carbonate Rotary Spin Flash Dryer

- Category: >>>

- Supplier: Liaoyang Wanda Machinery Co. Ltd.

Share on (60751657881):

Product Overview

Description

XSG Model Calcium Carbonate Rotary Spin Flash Dryer

![]()

Application:

Organic compounds: atrazine( onsecticde of agrochemicals), cadmium laurate, benzoic acid, germicide, sodium axalate, cellulose acetate and so on.

Dyestuff: anthraquinone, black ferric oxide, indigo blue pigment, butyric acid, titanium hydroxide, zinc sulfuration, all kinds of intermediate of azo dye-stuff.

Inorganic compounds: borax, calcium carbonate, hydroxide, copper sulphide, ferric oxide, barium carbonate, antimony tnoxide, all kinds of metallic hydroxide, kinds of heavy metallic salet, synthetic cryolite and so on.

Foodstuff: soya protein, agglomerative starch, less, triticin, wheat starch and so on.

Cellulose: HPMC ( hydroxypropyl methyl cellulose), microcrystalline cellulose.

Description:

Flash evaporation dryer, the model successfully developed in 1970. At that time, in order to solve drying for the chemical industry high viscosity, paste materials, the crystallization moisture of the product, mud and sludge cake. This model for drying the above material plays on its unique performance. In subsequent decades, through scholars and enterprises constantly updated, it has reached a perfect level to design and manufacture at our company. We have the ability, confidence, interested in research and development flash dryer at the application and popularization of the various industries.

Principle:

Cold air is sent to the air heater through the air filtered by fan. The heated air entry to the bottom of drying tower as appropriate wind speed, and (installed in the drying tower up) wet materials through spiral feeder which produced a strong shear cutting, blowing floating, rotating, crush(external mechanical force) and so on. This process will be that air transfer heat and separated with materials, taken away by air. The air is also reduced because the heat transferred. It used cyclone separation and high-voltage pulse bag filter to separate products and air, exhaust emissions away by the suction fan.

Features:

1 Product moisture can be controlled through adjusted parameters and equipment’s structure, meet the majority dry materials, the scope of application is large.

2 Materials were highly decentralized state by the hot air and outside mechanical shear, collisions, broken, centrifugal effects, increased the surface area. Evaporation volume is high intensity, small equipment, and large scale production.

3 Material in the dryer stay within a short time, material drying process is not warming, also adapted to dry heat-sensitive materials.

4 Equipment structure can be adjusted to meet product fineness requirements.

5 Compared with similar drying equipment, this model has high thermal efficiency ( some material drying, the thermal efficiency can be achieved 75%)

Structure chart:

Product technical parameter:

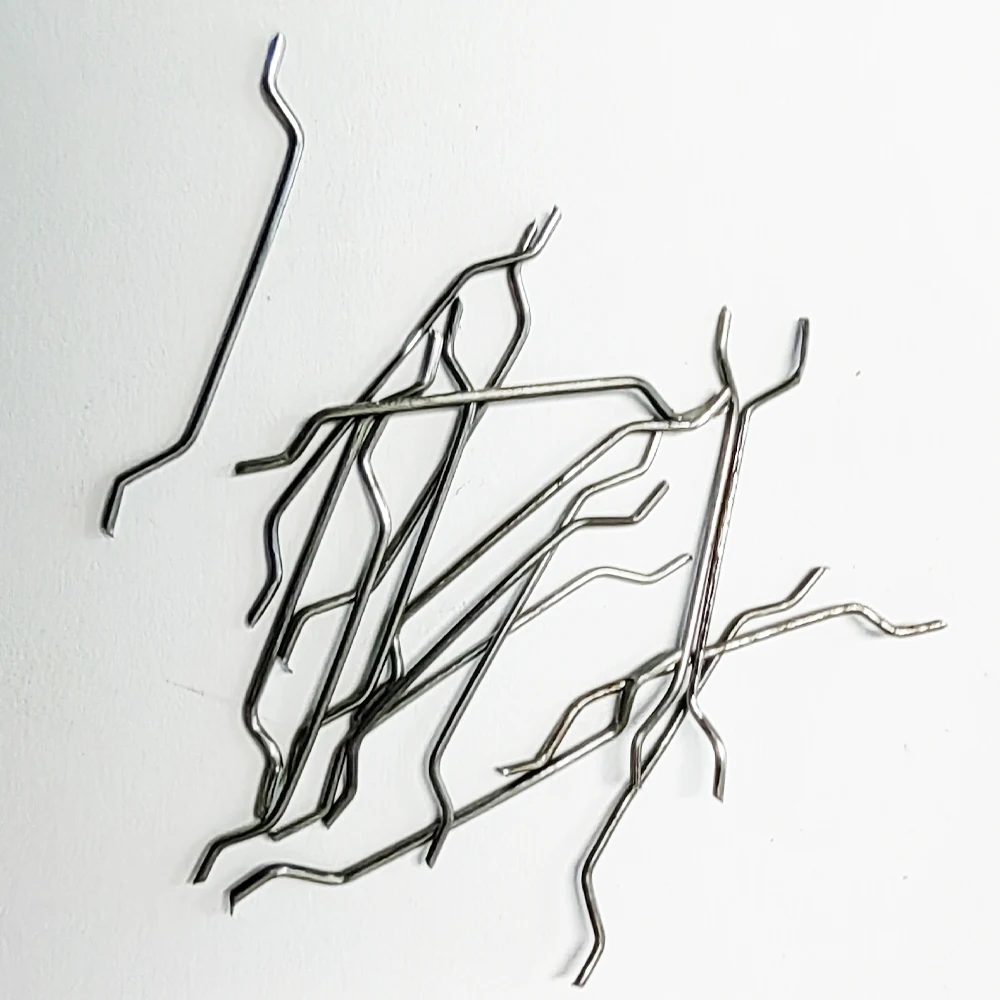

Product picture:

![]()

1.We will provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

2. Consultant services for whole machine life, 24 hours technical support by email and telephone.

3.Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

LIAOYANG WANDA MACHINERY CO.,LTD is specialized in design, development, manufacture and sale of pharmaceutical, chemical and packaging machinery.Our products include filter, centrifuge, mixer, tablet press machine, granulator, dryer, packing machine, teabag packing machine, etc. Looking to the future with a commitment to design innovation and quality products, supported by an outstanding level of customer service. The unexcelled quality medical machinery can be easily obtained from us because we maintain the quality and standard of our products from incoming raw materials to the finished products. Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process. Our research and development wing is our asset that develops and incorporates innovative ideas and products. Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our medical machinery. Our products are far sold to Europe, U.S.A., and the southeast Asia. They are well received by customers both at home and abroad.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices