pig poultry farm Automatic environmental climate controller panel ECT8

- Category: >>>

- Supplier: Gaotang County Guoyou Machinery Equipment Co. Ltd.

Share on (60757328142):

Product Overview

Description

Poultry environmental climate controller for house

Environmental Controller

IP65 waterproof enclosure, size: 245 * 195 * 98mm.

input:1)Four temperature sensors can be connected (P4 can be used outdoors), can access a humidity sensor (4-20mA).

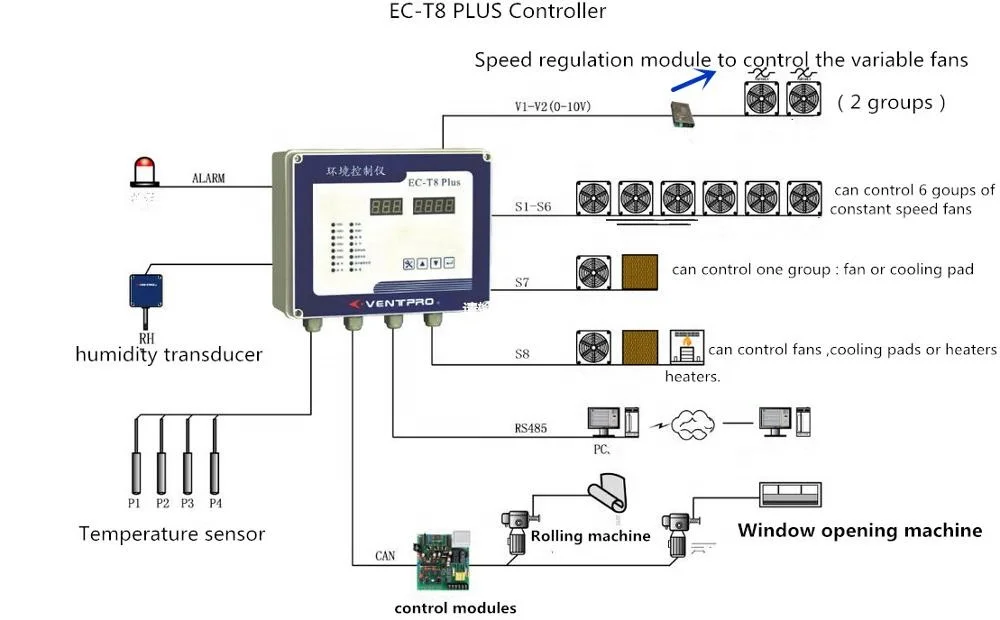

output: Group 2 variable speed fan, 8 groups constant speed fans, a group of heaters (and S8 multiplexing), a set of wet curtain (with S7 multiplexing), a group alarm output, ventilation opening control, shutter opening control

Function:

- Minimum ventilation timed cycle.

- Horizontal, vertical fan automatically switches.

- High and low temperature alarm, sensor failure alarm.

- Temperature curve, the minimum ventilation curve function.

- Humidity compensation, outdoor temperature compensated control

- IP65 waterproof enclosure, size: 245 * 195 * 98mm.

- Unique fan start protection to prevent the fan while starting current is too large

- 8 phase control

Overview

This device is used for ventilation control in closed-type livestock buildings.

It allows the user, according to the signal of the temperature probes, to

maintain the ambient temperature and humidity of the building on a

specified curve by controlling the operation of ventilation, heating and mist

cooling so as to meet the requirements for the growth of livestock.

FEATURES:

High-performance CPU:

MicroChip PIC18F4685, the latest product of Microchip, is used as the

main CPU of the controller. With the instruction cycle of 160ns, it’s the one

of the highest performance 8-bit Micro-controller products in the world

Control Object:

The 8-stage controller is used to control the fans, heaters and mist cooling

units. Among others, V1/V2 control the variable-speed fans, Stage 1-6

control the constant-speed fans. Stage 7 can be configured as fans or

cooling units. Stage 8 can be configured as fans cooling units or heaters.

EC-T8 Controller can also set the opening degree of the ventilation

window and curtain according to the setting of the fans.

EC-T8 controller offers two 0-10VDC outputs. It can also control the

variable-speed fan(V1,V2) with the use of EC-TY module.

Independent temperature probe:

Up to four temperature probes (three indoor and one outdoor) and one

humidity probe can be connected to the controller, which enables the

machine to obtain a more accurate reading of the average room

temperature with a faster reaction time. Access to the number of

temperature sensors can be set up.

Temperature controlling curve:

The controller can be set to automatically change the temperature and

humidity in accordance with the user’s requirements by specifying a

temperature curve with up to six different points each. The coordinates of

the curve are (days, temperature). The controller will adjust the

temperature and humidity according to the specified curve in a linear

fashion. When the last point of the curve is reached, the temperature set

point for that day is maintained until the curve is reactivated.

Minimum Ventilation Curve:

The minimum ventilation curve ensures indoor oxygen supply and proper

humidity of the room. The minimum ventilation curve can be defined by the

user and adjust the minimum ventilation of the building according to the

age of the animals.

Outside Temperature Compensation:

The minimum ventilation curve of Stage 1 fans can change automatically

according to the outside temperature. When the outside temperature

compensation option is correctly set, the opening duration of the minimum

ventilation curve reduces as the outdoor weather gets colder and the totle

cycle time of the curve remains unchanged, which effectively reduces the

decrease of the room temperature.

- 6 -

Humidity Compensation:

When the humidity level is too high, the cooling equipment (such as mist

cooling unit) can be turned off or the next Stage fans can be turned on.

Alarm Settings:

High/low temperature alarms and display can be defined. The defective

temperature probe can be indicated.

Cross and Tunnel ventilation:

In the livestock building, as the temperature rises, the ventilation mode

changes from cross ventilation to tunnel ventilation gradually. In the tunnel

ventilation mode, the cross ventilation fans will turn off so as to level off the

temperature difference in the room.

Special Protection Measures:

The special fan startup protection can avoid high current when fans turn

on simultaneously. If the controller is defective, the built-in minimum

ventilation ensures that catastrophic accident can be avoided.

Overload and overvoltage protection:

Fuses are installed at the input and outputs of the controller to protect its

circuitry in the case of an overload or overvoltage.

Computer network:

Within a certain area, the controllers can be connected by RS485 lines

and managed by one computer. The computer collects the real time

running data of all online controllers and can set the parameter of the

controller. The collected running date can be released through the Internet.

See enclosed wiring diagram 2.

including :

controller 1 set

Temperature Sensors 2 pcs

Instructions 1 pcs

We can customized the control box based on client's request

If you have any questions ,feel free to contact me

We Recommend

New Arrivals

New products from manufacturers at wholesale prices