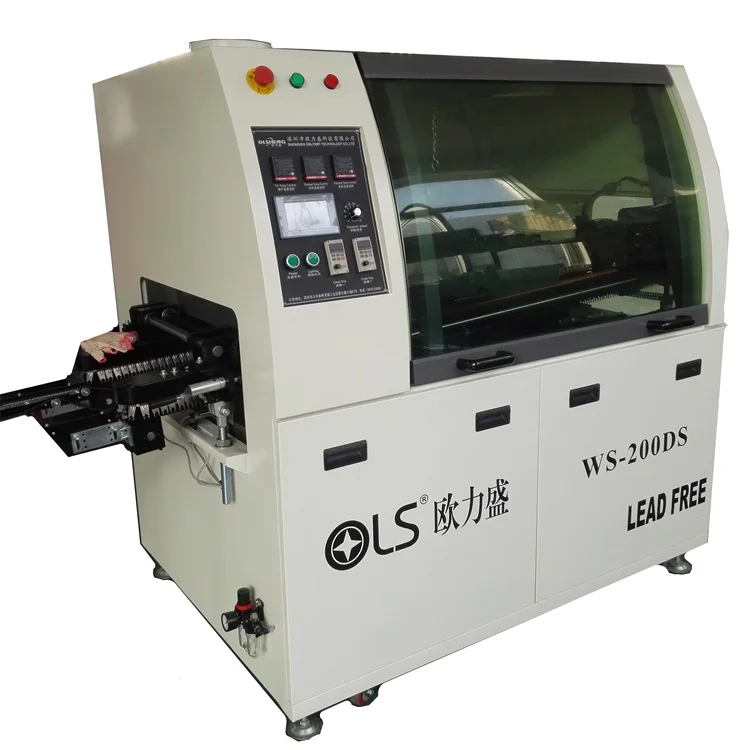

Small wave Soldering Machine economic automatic DIP soldering machine line LED Driver home appliances toy main board soldering

- Category: >>>

- Supplier: Shenzhen Wanbo Hi-Tech Co. Ltd.

Share on (60761358744):

Product Overview

Description

Economic type 50-200mm width PCB dual wave soldering machine

mini wave soldering machine, selective wave soldering machine, lead free wave soldering machine

Product Features:

1. Open canopy streamlined shell design, beautiful appearance, easy to clean.

2. The soldering furnace is made of alloy materials. High-strength and high-hardness special aluminum alloy guide rail with long service life.

3. Adopt German Siemens PLC+ touch screen control technology to ensure system reliability and stability.

4. The rodless air cylinder spray device can automatically adjust with the width of the PCB, effectively saving flux.

5. The wave peaks of the tin furnace adopt stepless electronic frequency conversion speed regulation, which can independently control the wave peak height.

6. Unique flux isolation device, flux fumes are discharged from dedicated exhaust and recovery channels.

Technical Parameters:

Model | Wave soldering machine WS-200DS | |||

Substrate width | Max200mm | |||

PCB board transport height | 760±10mm | |||

PCB board transport speed | 0-1.8M/Min | |||

Preheating zone length | 700mm | |||

Number of preheating zones | 2 | |||

Preheating zone power | 4kw | |||

Preheating zone temperature | Room temperature - 200 ° C | |||

heating method | Full hot air | |||

Number of cooling zones | 1 | |||

cooling method | Natural wind cooling | |||

Tin furnace power | 6kw | |||

Tin furnace tin content | 120-150KG | |||

Tin furnace temperature | Room temperature - 300 ° C | |||

Transportation direction | about | |||

Temperature control method | Temperature control table control | |||

Machine control mode | Instrument control + touch screen / PC control | |||

Flux capacity | Max4.2L | |||

Spray method | Japan SA-6 nozzle | |||

power supply | 3-phase 5-wire system 380V/220 | |||

Starting power | 10kw | |||

Normal operating power | 3kw | |||

Gas source | 4-7KG/CM2 12.5L/Min | |||

Rack size | L1450×W1100×H1600MM | |||

Dimensions | L2250×W1100×H1600MM | |||

weight | Approx 550kg | |||

Spray part | ||||

Spray Nozzle | Spray range 20-65mm fan surface adjustable, Spray height 50-200mm adjustable, maximum flow rate 60ml/min | |||

Spray drive system | Stepper motor controls the mobile system, further improving the quality | |||

Spray drive unit | Imported filters, control valves and fittings | |||

Preheating unit | ||||

Extended preheating zone | Total length 700mm, two-stage full hot air temperature independent control | |||

Temperature control mode | Temperature meter | |||

Heating unit | Hot air control, imported Taiwan heating core | |||

Preheating power | Total power 4kw | |||

Tin furnace parts | ||||

Tin furnace material | Lead-free material 3MM thick | |||

Tin furnace tin volume | 120-150kg | |||

Tin furnace temperature range | Room temperature - 300 ° C | |||

Height adjustment range | 0—50mm | |||

Tin furnace power | 6kw | |||

Tin furnace move mode | Manual | |||

Wave spray head | Guaranteed plane tin wave | |||

Economical operation | Through the PLC and photoelectric switch control, the plate sprays the wave function to reduce unnecessary waste. | |||

Wave motor | Taiwan Taichuang company high temperature motor, peak height digital adjustment | |||

Heating unit | Special long life, special solid state relay, tin liquid heating are ± 2 ° C | |||

Cooling system (standard) | ||||

Cooling method | Natural wind cooling | |||

PCB transfer system | ||||

High strength wear-resistant rail | The special aluminum guide rail uses high temperature and wear resistance, and the special thermal compensation anti-deformation and telescopic structure of the stainless steel guide rail ensures that the guide rail does not deform or not. | |||

Rail parallelism | 0.5mm | |||

Widening | Manual adjustment | |||

C/V speed setting minimum unit range | Minimum unit 10mm/min 0-1800mm/min | |||

C/V speed deviation range | Electronic closed loop control within 0-10mm/min | |||

Chain tensioning device | Sprocket adjustment tension | |||

Transport motor | Three-phase inverter 90W motor | |||

After-sales service responsibility area | China region | |||

1. Can you do OEM?

Yes. Also can be customized according to the customer's specific requirements.

2. If 110V is available?

Yes. 110V and 220V can be switched arbitrarily.

3. What kind of plug does your product equip with?

American or Australian or European or UK plug or other types of plug.

We Recommend

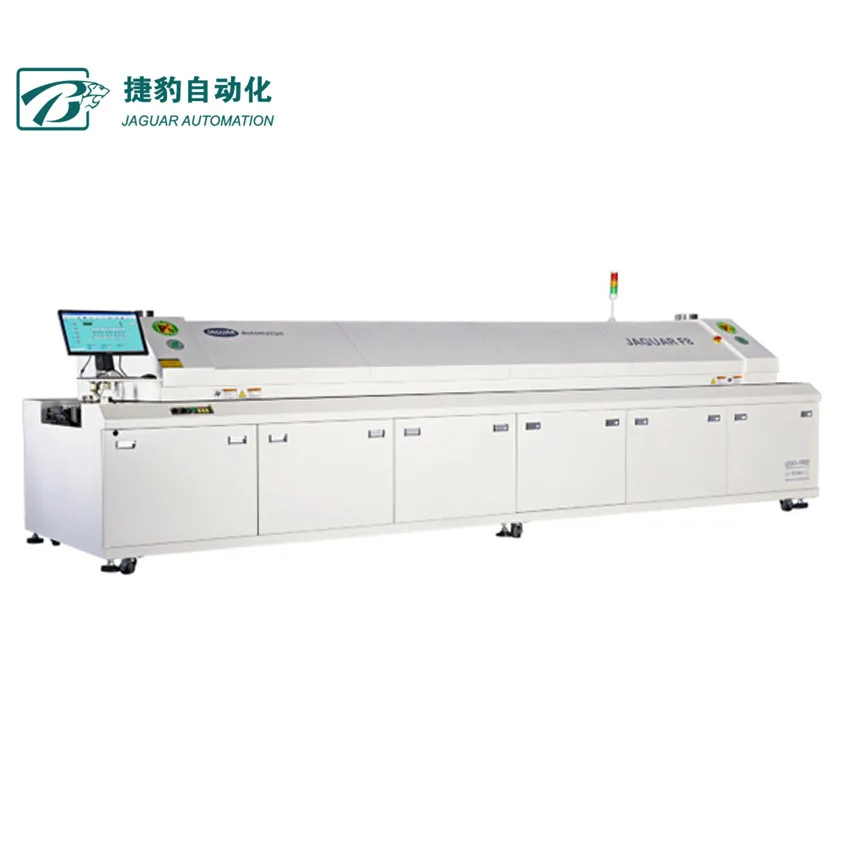

Power Module Device Vacuum Reflow Oven KD-V10N China Factory Vacuum Soldering Oven

Hanwha SM482 Plus Pick and Place Machine

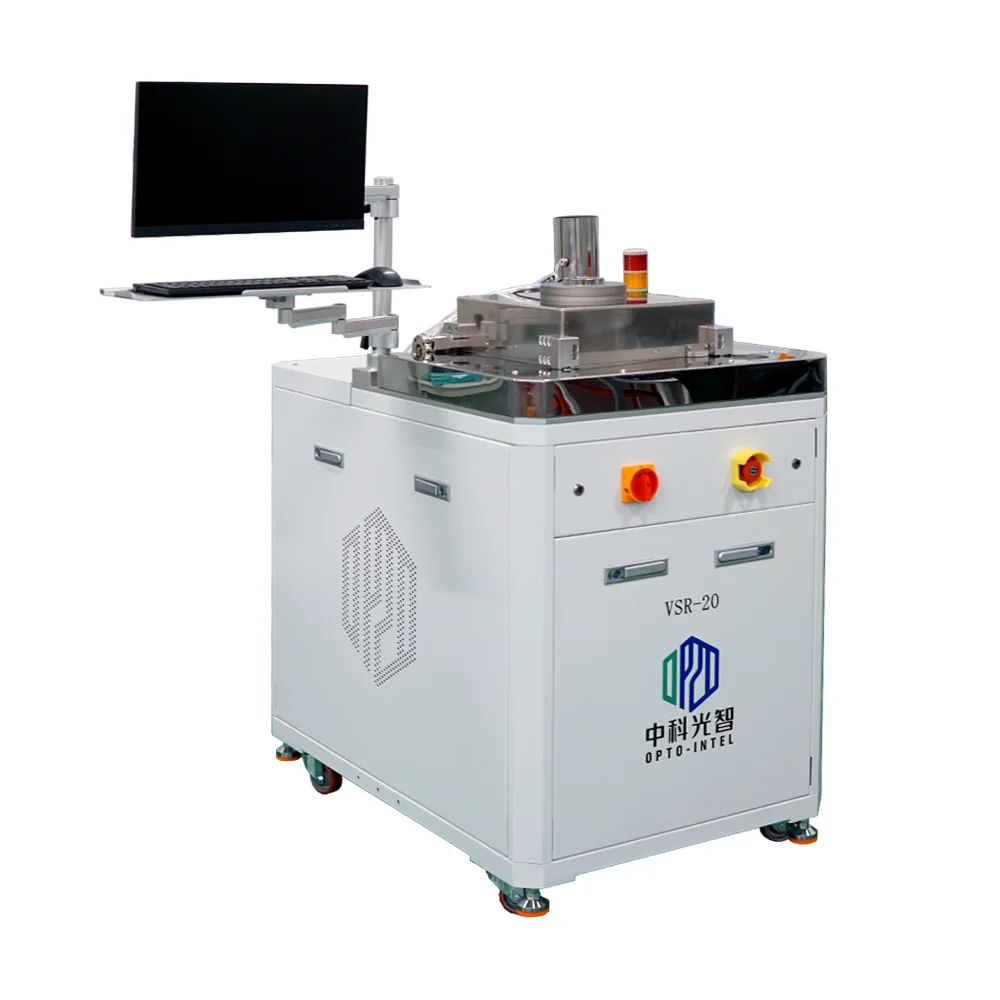

Vacuum Soldering Furnace Formic Acid Vacuum Soldering System IGBT Module Packaging Oven

New Arrivals

New products from manufacturers at wholesale prices