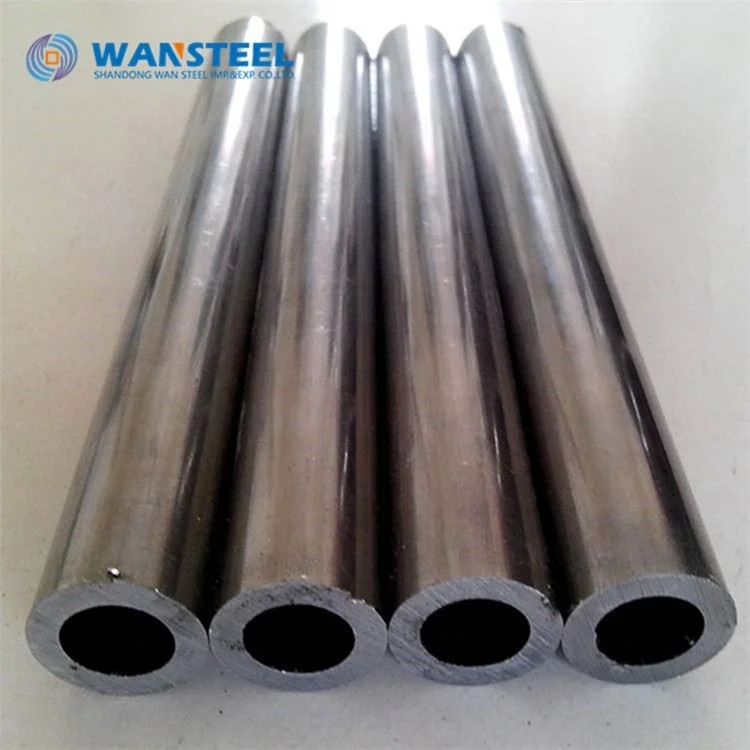

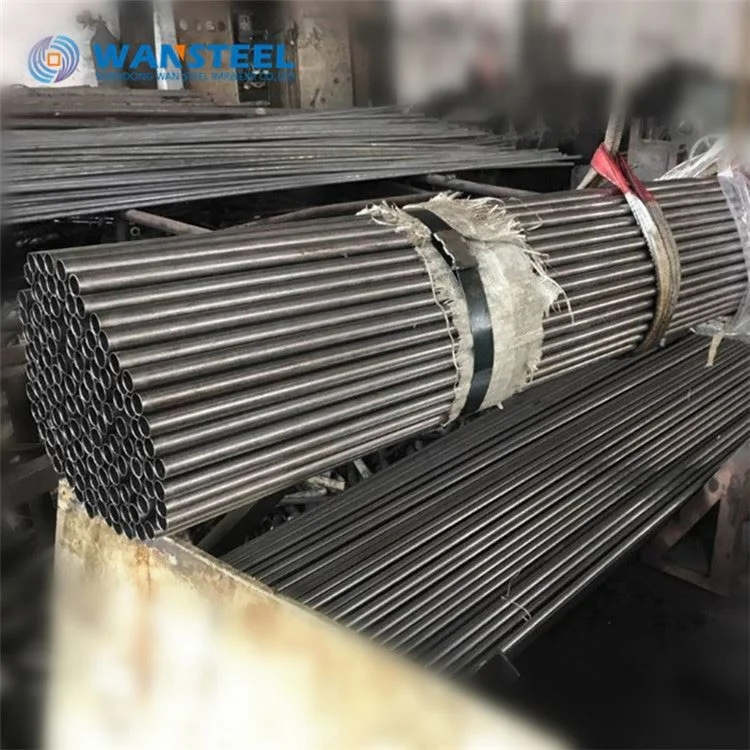

Precision Chrome Moly Alloy Steel Tube 4130 / 4140 / 30CrMo4 / 42CrMo4

- Category: >>>

- Supplier: Shandong Wan Steel Imp. & Exp. Co. Ltd.

Share on (60762198344):

Product Overview

Description

Precision Chrome Moly Alloy Steel Tube 4130 / 4140 / 30CrMo4 / 42CrMo4

OD: 3mm-150mm

Wall thickness: 0.4mm-15mm

Tolerance of diameter: ≤±0.05mm;

Tolerance of W.T.: ≤±0.05mm;

Concentricity: ≤0.05mm

Straightness : 0.30mm/m

DN — Nominal Diameter

NPS —Nominal Pipe Size

1. High dimensional accuracy, the tolerance of inner and outer diameter size can be accurate to within 0.05mm, better tolerance can controled wihthin 0.025mm. Precision H8-H10

2. Good surface smoothness finish;

3. Good cleanliness, inside and outside surface no oxide layer

4. Can withstand high pressure, cold bending, flaring flattening, without cracking/ wrinkled

5. Excellent overall performance, can make a variety of complex deformation and machining.

For mechanical and pressure use,and also for transporting steam,water,gas and etc.

ASTM A519 specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished.

1.Auto parts ;Gas spring;Motor housing, dc motor;Industrial processing: machine parts, bearing sleeve, Hydraulic cylinder ,air cylinder;Other: electrical gas transmission, water generation fluid pipeline, etc.

| \t | |||||||

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | ||||

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

Please note the meaning of below abbreviation :

HR----Hot Rolled

CW----Cold Worked

SR----Stress Relieved

A----Annealed

N----Normalized

1. BK (+C) No heat treatment after last cold forming process.

2. BKW (+LC) After last heat treatment there is a light finishing pass (cold drawing)

3. BKS (+SR) After the final cold forming process the tubes are stress relieve annealed.

4. GBK (+A) After the final cold forming process the tubes are annealed in a controlled atmosphere.

5. NBK (+N) After the final cold forming process the tubes are annealed above the upper transformation point in acontrolled atmosphere.

Factory Equipment

2.Wooden case by customer requirement

3.Label as customer requirement

SHANDONG WAN STEEL Import and Export Co., Ltd., belong to WAN STEEL Group ,locate at Taishan steel Industry park ,Tai’an City, Shandong province. We are professional steel pipe supplier with more than 30 years experience. We cooperate closely with many large companies at home and abroad, and have set production base in Shandong , Jiangsu,Tianjin , Foshan ect. Our main products are seamless steel pipe, spiral steel pipe, welded steel pipe, hot dipped galvanized steel pipe, precision alloy seamless steel pipe and stainless steel seamless pipe . We have various kinds of pipe in large stock at any time, can meet your individual requirements in terms of quantity and quality. Our products get the ISO9001 quality certificate; French BV, SGS ,China CCS. API; Britain CE certificate, the approval of ISO14000 environmental management system and OSHMS occupational health and safety management system.

Stainless steel capillary tube

Seamless steel tube

Spiral pipe

Q: Are you trading company or manufacturer ?

A: We are factory with more than 30 years experience. We cooperate closely with many large companies at home and abroad, and have set production base in Shandong , Jiangsu,Tianjin , Foshan ect.

Q: How long is your delivery time?

A: 20-30 working days after receiving deposit

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

We Recommend

New Arrivals

New products from manufacturers at wholesale prices