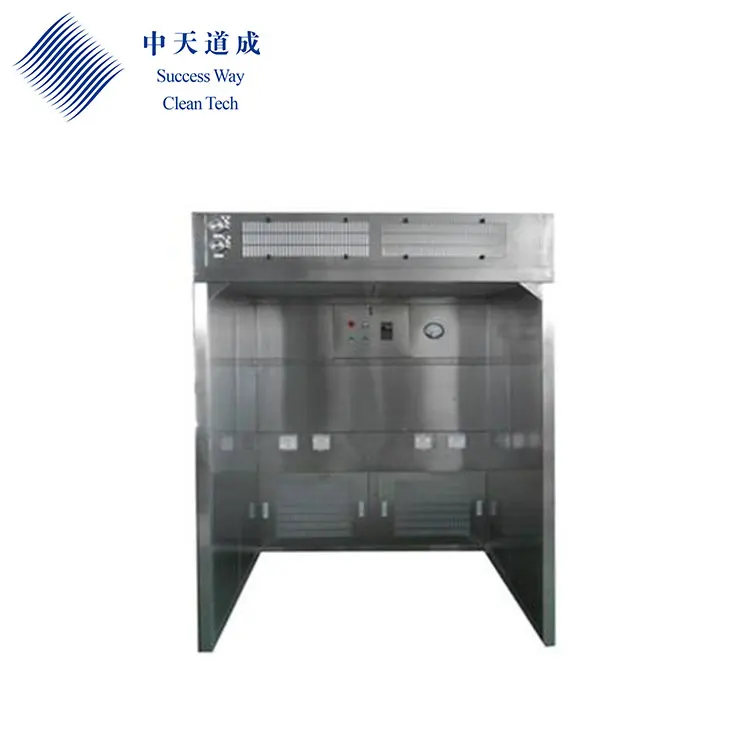

Compact Portable Pharmecutial Clean Room Sampling Booth With Great Price

- Category: >>>

- Supplier: Success Way (suzhou) Clean Tech Co. Ltd

Share on (60768820938):

Product Overview

Description

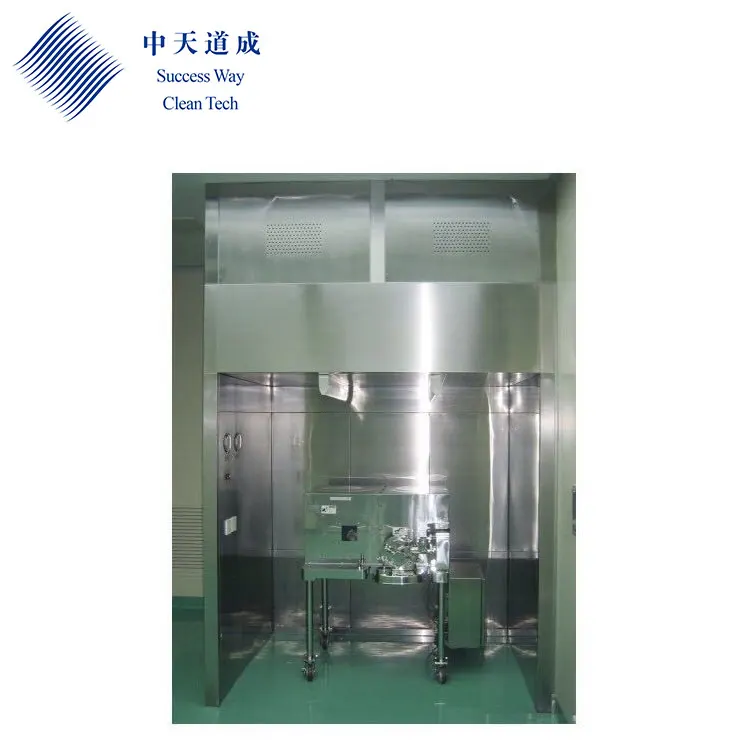

Weighing Booth/Dispensing Booth

Negative pressure dispensing/sampling/ weighing room is a control environment specifically designed for precise weighing and handling of harmful substances such as dust, chemicals, or drugs. Its main purpose is to ensure the safety of operators, prevent harmful substances from spreading outside the work area, and protect the working environment.

It is a closed space equipped with a negative pressure system that ensures that any air and particles can only flow in from the outside

and not out of the room by keeping the indoor air pressure lower than the external air pressure. This design effectively prevents

the spread of harmful substances, protecting operators and the surrounding environment.

It is a closed space equipped with a negative pressure system that ensures that any air and particles can only flow in from the outside

and not out of the room by keeping the indoor air pressure lower than the external air pressure. This design effectively prevents

the spread of harmful substances, protecting operators and the surrounding environment.

Product Paramenters

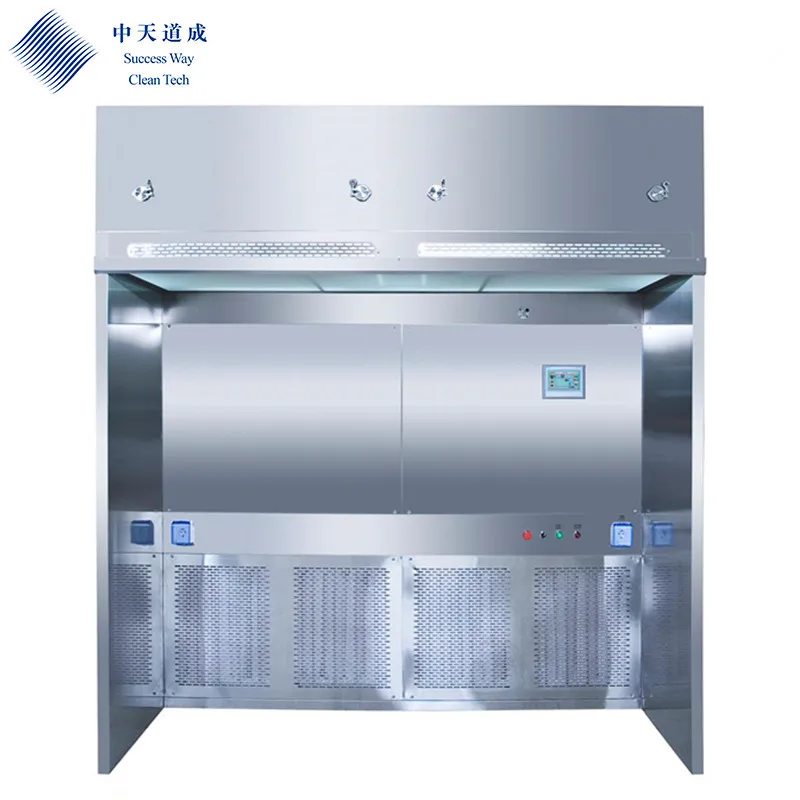

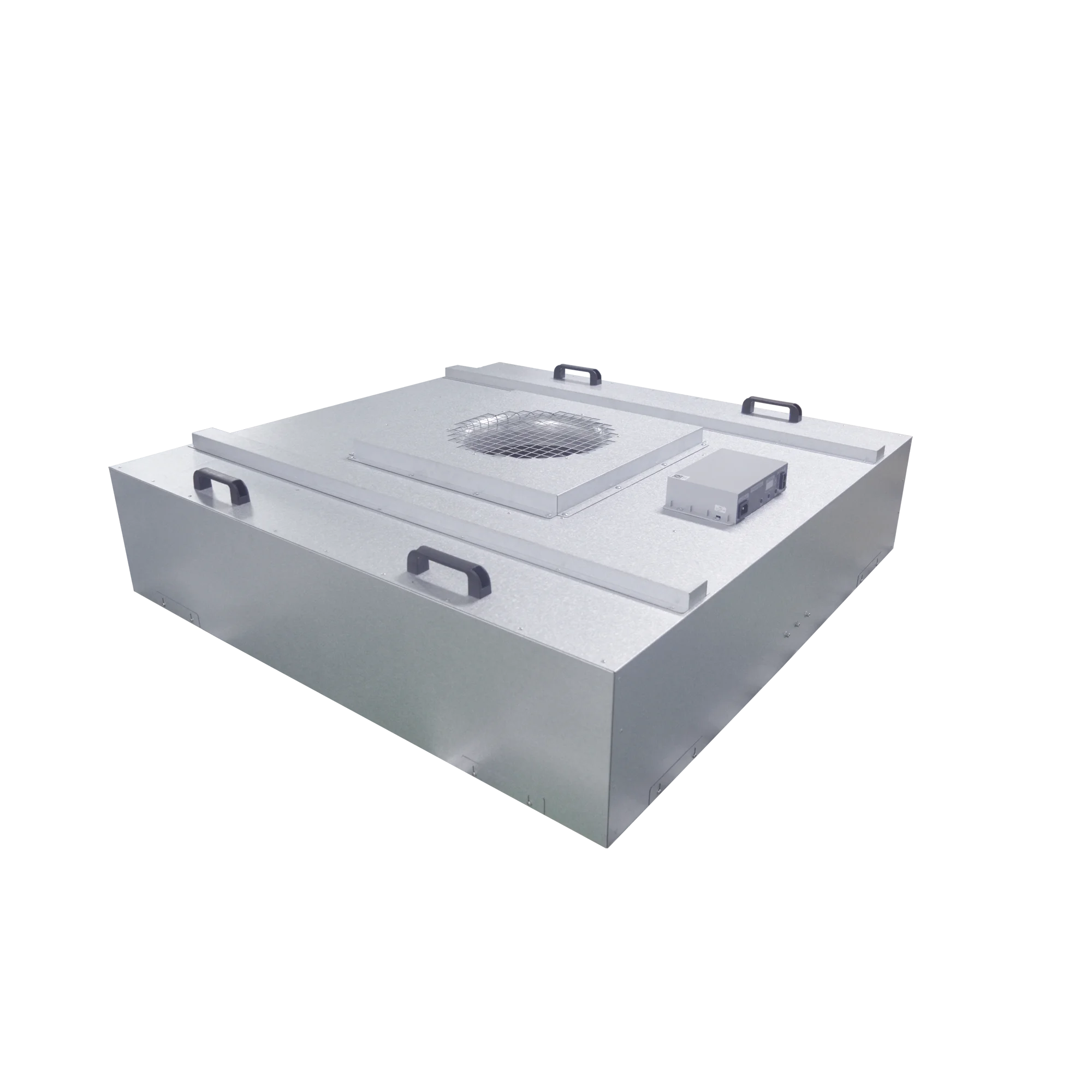

-Efficient HEPA filtration system: ensures 99.995% particle filtration efficiency and provides a clean operating environment.

-Modular design: convenient for assembly and disassembly, suitable for different workspace requirements.

-Constant airflow system: Ensure stable airflow and prevent pollutants from entering the sampling area.

-High quality materials: Made of stainless steel and chemically resistant materials, easy to clean and maintain.

-Digital control panel: easy to operate, real-time monitoring of environmental parameters.

-Modular design: convenient for assembly and disassembly, suitable for different workspace requirements.

-Constant airflow system: Ensure stable airflow and prevent pollutants from entering the sampling area.

-High quality materials: Made of stainless steel and chemically resistant materials, easy to clean and maintain.

-Digital control panel: easy to operate, real-time monitoring of environmental parameters.

Products Specification

Dispensing/Sampling/Weighing Booth Room

Model | DB-1650 | DB-1900 | DB-3100 | ||

External Dimension (W*D*H) (mm) | 1650*2150*2400 | 1900*1700*2500 | 3100*2700*2500 | ||

Internal Dimension (W*D*H) (mm) | 1550*1550*1900 | 1800*1200*2000 | 3000*2000*2000 | ||

HEPA Filter Efficiency | ISO 5/Class 100, H14,≥99.995%@0.3um | 1220*1220mm | |||

Air Velocity (m/s) | 0.45m/s±20% | ||||

Control Mode | VFD/PLC (optional) | 18 | 24 | ||

Material | full SUS 304 outside and inside/full SUS 316L outside and inside | ||||

Power Consumption | 2.0KW | 2.2KW | 6.5KW | ||

Power Supply | AC380/220V,3 phase,50/60Hz (Optional) | ||||

Working Principles

1. Creation of negative pressure environment

The negative pressure weighing room creates and maintains a negative pressure environment through a specially designed ventilation and air handling system. The main principle is to exhaust indoor air, causing the indoor pressure to be lower than the external pressure, forming a negative pressure state.

2. Air flow and filtration system

The negative pressure weighing room is equipped with an efficient air flow and filtration system to ensure air quality and safety.

a. Air flow

Air intake system: Fresh air enters the negative pressure weighing room through the air intake system. The intake system is usually equipped with a pre filter to remove large particles.

Air flow direction: Air enters the weighing room from the intake and is drawn away after passing through the weighing area. The airflow direction is usually designed to flow from the clean area to the contaminated area to avoid cross contamination.

b. Exhaust system

Exhaust fan: The exhaust fan in the exhaust system continuously extracts indoor air and maintains negative pressure inside the room.

Filter: Install HEPA (High Efficiency Air Particle Filter) or ULPA (Ultra Low Permeability Air Filter) in the exhaust system to filter out particles and harmful substances in the air, ensuring that the air emitted to the outside is clean.

3. Differential pressure control

The negative pressure weighing room maintains the pressure difference between indoor and outdoor through a pressure difference control system.

Pressure difference sensor: The pressure difference sensor installed indoors and outdoors monitors the pressure difference in real time.

Automatic adjustment system: The pressure difference control system automatically adjusts the working status of the exhaust fan based on sensor data, ensuring a constant negative pressure indoors.

4. Sealing design

The sealing design of the negative pressure weighing room is the key to ensuring the effectiveness of the negative pressure environment.

Door and window sealing: All doors, windows, and openings are made of high-quality sealing materials to prevent air leakage.

Structural sealing: The entire weighing room structure adopts a strict sealing design, including the joints of walls, floors, and ceilings.

5. Real time monitoring and alarm system

The negative pressure weighing room is equipped with a real-time monitoring and alarm system to ensure safe operation.

Display panel: Real time display of parameters such as indoor and outdoor pressure difference, airflow velocity, and filter status.

Alarm system: When the pressure difference, airflow speed, or filter status is abnormal, the system will issue an alarm signal to prompt the operator to take corresponding measures.

The negative pressure weighing room creates and maintains a negative pressure environment through a specially designed ventilation and air handling system. The main principle is to exhaust indoor air, causing the indoor pressure to be lower than the external pressure, forming a negative pressure state.

2. Air flow and filtration system

The negative pressure weighing room is equipped with an efficient air flow and filtration system to ensure air quality and safety.

a. Air flow

Air intake system: Fresh air enters the negative pressure weighing room through the air intake system. The intake system is usually equipped with a pre filter to remove large particles.

Air flow direction: Air enters the weighing room from the intake and is drawn away after passing through the weighing area. The airflow direction is usually designed to flow from the clean area to the contaminated area to avoid cross contamination.

b. Exhaust system

Exhaust fan: The exhaust fan in the exhaust system continuously extracts indoor air and maintains negative pressure inside the room.

Filter: Install HEPA (High Efficiency Air Particle Filter) or ULPA (Ultra Low Permeability Air Filter) in the exhaust system to filter out particles and harmful substances in the air, ensuring that the air emitted to the outside is clean.

3. Differential pressure control

The negative pressure weighing room maintains the pressure difference between indoor and outdoor through a pressure difference control system.

Pressure difference sensor: The pressure difference sensor installed indoors and outdoors monitors the pressure difference in real time.

Automatic adjustment system: The pressure difference control system automatically adjusts the working status of the exhaust fan based on sensor data, ensuring a constant negative pressure indoors.

4. Sealing design

The sealing design of the negative pressure weighing room is the key to ensuring the effectiveness of the negative pressure environment.

Door and window sealing: All doors, windows, and openings are made of high-quality sealing materials to prevent air leakage.

Structural sealing: The entire weighing room structure adopts a strict sealing design, including the joints of walls, floors, and ceilings.

5. Real time monitoring and alarm system

The negative pressure weighing room is equipped with a real-time monitoring and alarm system to ensure safe operation.

Display panel: Real time display of parameters such as indoor and outdoor pressure difference, airflow velocity, and filter status.

Alarm system: When the pressure difference, airflow speed, or filter status is abnormal, the system will issue an alarm signal to prompt the operator to take corresponding measures.

Advantages

1. Protect operators: prevent harmful substances from spreading outside the operating area and reduce the risk of operators coming into contact with harmful substances.

2. Environmental safety: Effectively control the spread of harmful substances, protect the safety of the work environment and surrounding environment.

3. High precision weighing: A stable negative pressure environment and clean air flow help achieve high-precision weighing operations.

4. Compliance with regulations: Meet the requirements of international standards and regulations such as GMP (Good Manufacturing Practice) and OSHA (Occupational Safety and Health Administration).

3. High precision weighing: A stable negative pressure environment and clean air flow help achieve high-precision weighing operations.

4. Compliance with regulations: Meet the requirements of international standards and regulations such as GMP (Good Manufacturing Practice) and OSHA (Occupational Safety and Health Administration).

Details Images

Engineer Design Capability

Product packaging

Customer Visit

Why Choose Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices