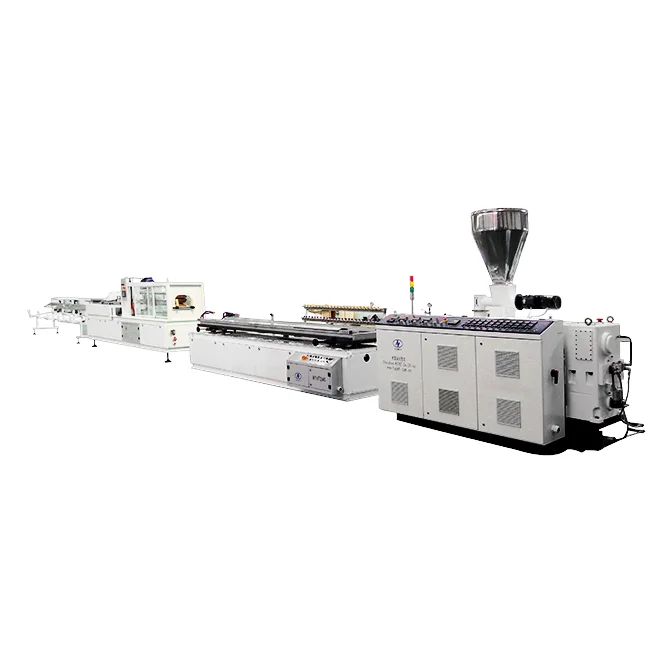

conch pvc sliding window profile making machine

- Category: >>>

- Supplier: Shenzhen HYPET Co. Ltd.

Share on (60796543144):

Product Overview

Description

conch pvc sliding window profile making machine

HYPET Advantages

New generation gear box to put bearings near to the screws not in the far back;

HYPET Extruder + die device to make the profile more hard & bright;

HYPET barrel in two parts bi-matal, and totally hard alloy ensure more than 3 years; (less than 75 CaCo3)

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t | ||

| \t | \t | ||

| \t | \t | \t | \t |

| \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | |||

| \t | \t | \t | \t |

| \t | \t | \t | |

SRL-Z500/1000 Mixer

Condition of use

The output for this mixer is 480kg/h

It can be used for mixing raw PVC material with additives, it consist of hot mixer and cold mixer,

Power supply:\t 380V/three phases, 50Hz /90 kW

Features

1.\tApplied to all kinds of plastic techniques such as mixture, mixing, drying, coloring, preferences

2.\tSpindle seal has special structure with two heating functions of electrical heating and vapor heating.

3.\tThe mixer cover adopt double sealing, hot compounding cover with pneumatic start, and cooling compounding cover with pneumatic or manual start.

4.\tThe electric control system adopts Siemens control components to realize automatic control.

5.\tEquipped with pulse dust catching device.

6.\tBoth the blades and belt wheel have been specially treated through static-dynamic balance test.

7.\tThis mixer equipped with vacuum auto loader.

Material tank (2 tons capacity)

To connect to mixer and extrusion lines, so the mixer no need always working.

HYZS-65/132 conic twin screw extruder

Barrel is Nitro Alloy with bi-metal in two parts for longer working life.

Screw has internal closed loop heat balancing system by means of distilled water

The harden and ground gear box is made with German technology.

Twin output shaft Helical Gear Box. Gears are hardened and ground. Both output shafts are integral with high capacity thrust bearings to absorb axial thrust generated during the extrusion process

Gear box housing is made of high quality Ductile iron QT-500.

Lubricating pump with Heat Exchange, oil filter and oil flow indicator are provided for force lubrication of Thrust Gear box. The gears and bearings are forced lubricated. Gear box lube oil is circulated in a closed loop through heat exchange to maintain optimum oil temperature in gearbox.

Vacuum degassing system along with dust collector having bypass system & Vacuum pump.

Extrude mounted on rigid structural steel frame.

Quantitative feeding system with twin screw structure to avoid stagnant material.

Plug & Socket for Die head heating zones, Connecting head & Melt temperature indicator.

Display of Heating current for each temperature zone, manual override on all zones in case of sensor failure.

Drive control panel, equipped with panel water cooler, placed besides heating control panel with Independent Solaris for essential power supply.

Other eclectic and pneumatic components are made in world famous brand such as from Siemens from Germany etc

HYZS-51/110 conic twin screw extruder

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Four-head seamless welding machine

SHWD4-100×4500

Programmable controller (PLC) controls welding action/programs with high reliability.

The process parameters can be continuously adjusted to meet the needs of different profiles.

High reliability with high quality electrical components.

Double head cutting saw for PVC profile\tSJZ2-400x3500

It is used for 45° -90° cutting aluminum profiles.

Using straight-line push-in work method.

Pneumatic transmission for profile clamping and cutting.

The structure of the machine is stable, the operation is simple and flexible, and the angle accuracy of blanking size is high.

cutting saw

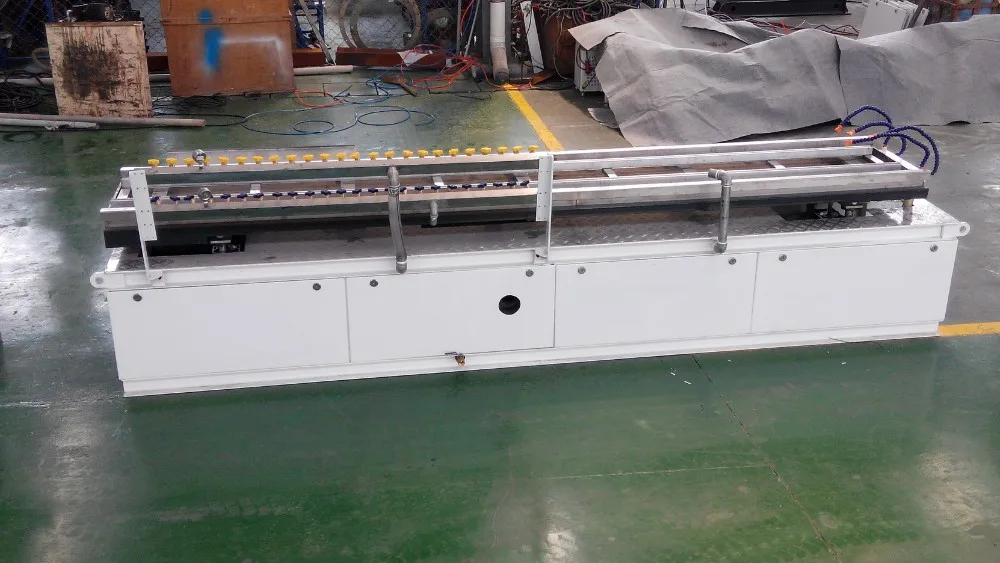

Water Slot Milling

Copy router & lock hole drilling

Strong Crusher HY-SC30.

It can be used for various recycling plastic parts,

It is cooled by water for working continue sly

Power supply:\t 380V/three phases, 50Hz

| \t | |

| \t | |

| \t | |

| \t |

| \t | \t |

| \t | \t |

| \t | |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices