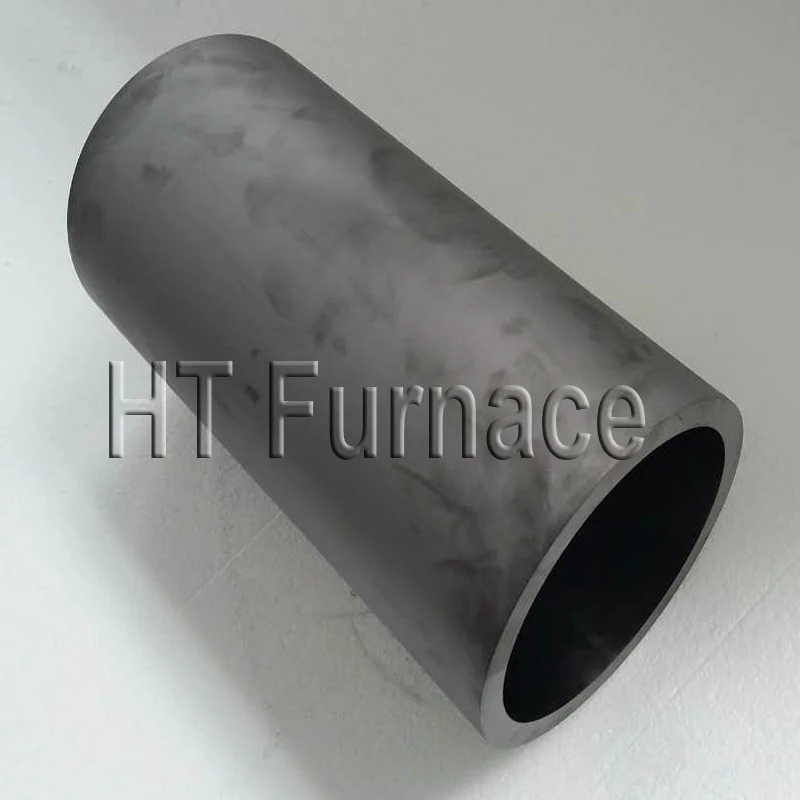

HengTong Good performance Graphite Rotor for DEGASSING ANTIOXIDE

- Category: >>>

- Supplier: Zhengzhou Hengtong Furnace Co. Ltd.

Share on (60816665700):

Product Overview

Description

Advantage:

1. Without contamination of impurities

2. High resistance to high temperature, lower down oxidation speed.

3. Excellent self-lubrication

4. Remarkable chemical corrosion resistance

5. High thermal conductivity and good thermal stability

6. Adequate mechanical strength and shock resistance

Applications

In the aluminum and zinc casting industries, nitrogen, argon or carbon tetrachloride are injected and sprayed into molten metal through graphite rotors for dehydrogenation. It can eliminate the bubbles inside the castings and improve their inner quality. Injects inert gases into the Metallic solution

Max. grain size: 0.042mm

Average grain size: 0.025mm

Density: 1.70g/cc, 1.75g/cc, 1.80g/cc, 1.85g/cc.

Resistivity: 15 μΩ.m max.

Compressive Strength: 50 - 78 Mpa

Flextual Strength: 25 - 38 Mpa

Elastic Modolus: 9.5 - 11.5 Gpa

Shore Hardness: 45 - 60

Ash Content: 0.05% - 0.2%

No. | Density | Porosity | Compressure strength | Blend strength | Specific Resistance | Ash Content | Graininess |

g/cm3 | % | MPa | MPa | μΩ.m | % | Mesh | |

≥ |

| ≥ | ≥ | ≤ | ≤ |

| |

TX172 | 1.72 | 20 | 34 | 18 | 8.5 | 0.3 | 0.8,2mm |

TX175 | 1.75 | 16 | 45 | 24 | 8.5 | 0.3 | 325mesh |

We usually quote within 24 hours after getting your detailed requirements,like drawing,size,quantity ,specification etc. .

Q: Do you provide samples?

Yes, samples are available for you to check our quality.

Q:What about the lead time for mass product?

The lead time is based on the quantity,sample need about 2-7days.bulk need about 7~20days.

Q:Product packaging?

Packed in sponge+paper box+export wood cases,or according to your requirements

Q:About the price on Alibaba

Please note that the price on Alibaba is a rough price.The actual price will depends on raw materials,exchange rate ,wage and your order quantity .

Hope to cooperation with you,Thanks !

We Recommend

New Arrivals

New products from manufacturers at wholesale prices