smc bmc Resin Manhole Cover making Machine hydraulic press

- Category: >>>

- Supplier: Zhongyou Heavy Industry Machinery Equipment Co. Ltd.

Share on (60843085493):

Product Overview

Description

smc bmc Resin Manhole Cover making Machine hydraulic press

The function of hydraulic machine: This series of products is suitable for the pressing process of various plastic materials, such as stamping, bending, tumbling, etc. It can also be used for correction, press fitting, grinding wheel molding, plastic products, rubber products and powder products. Forming, the working pressure, pressing speed and stroke range of the series can be adjusted within the specified range according to the process requirements.

This series of hydraulic press is a three-beam four-column structure, economical and practical, with high precision. With independent hydraulic pump station and electrical control system.

The hydraulic control adopts the cartridge valve integrated system, which has compact structure, reliable action, good sealing performance, long service life and convenient installation and maintenance.

The oil pressure is displayed by a digital display electric contact pressure gauge, and the upper limit of the oil pressure can be arbitrarily set within the allowable range as needed.

The electrical system adopts centralized control of buttons and has two operation modes: jog and semi-automatic.

The working pressure and stroke can be adjusted as required within the specified range, and both the constant pressure and the fixed stroke can be completed.

Technical parameters

Specification | Unit | YQ32-315A | YQ32-315B | YQ32-400 | YQ32-500 | |

Nominal force | Kn | 3150 | 3150 | 4000 | 5000 | |

Max pressure of hydraulic system | Mpa | 25 | 25 | 25 | 25 | |

Max. Opening height | mm | 1250 | 1250 | 1250 | 1500 | |

Slider effective stroke | mm | 800 | 800 | 800 | 900 | |

Working table size | mm | 1260*1160 | 1000*1100 | 1260*1160 | 1400*1400 | |

Nominal force of Ejection cylinder | Kn | 630 | 630 | 630 | 1000 | |

Ejection stroke | mm | 300 | 300 | 300 | 300 | |

Slider working speed (empty travel) | Mm/s | 120 | 120 | 120 | 150 | |

Slider working speed (press) | Mm/s | 8-15 | 8-15 | 8-15 | 10-22 | |

Slider working speed (Return stroke) | Mm/s | 90 | 90 | 90 | 120 | |

All series of hydraulic presses can be added with the following optional configurations according to user requirements:

1) Mobile workbench;

2) foot switch or handle;

3) PLC electrical control system;

4) Industrial touch screen;

5) grating protection device;

6) Safety protection devices;

7) Stroke and pressure digital display device;

8) upper and lower heating plates;

9) Hydraulic system cooling device

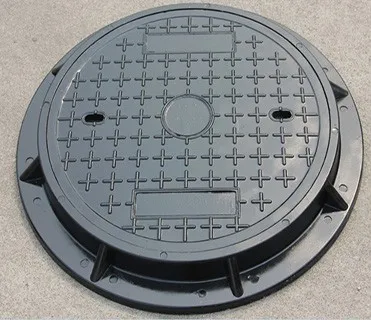

The new environmentally friendly SMC molded manhole cover is a new type of color high strength manhole cover, which is molded by advanced technology and equipment.

The raw materials of the two processes are basically the same, and they are pre-made molding materials such as resin, glass fiber, filler, etc., and then molded or injection molded products

Internal plastic moisture-proof anti-rust packaging,

External wooden packaging,

Exclusive container transport.

Delivery Time for High Speed Four Column Hydraulic Press Machine for Oil Filter:

Shipped in 30 days after payment

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in hydraulic press Machine .we mainly produces various hydraulic presses forging press and auto maintenance equipment with advanced technology and equipment.

3: Where is your factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

Our services are divided into pre-sale, sales, after-sale three parts.

Pre-sale

to provide detailed advice,the program recommended to the factory inspection, as far as possible to meet your questions and needs.

Sales

can support samples, support diversified payment methods, the solid forklift tire press machine production process transparent, standardized and quickly stocking.

After-sales

support diversification guidance, training, voice and video images, and even solid forklift tire press machine overseas site installation, on-site training, home maintenance, continuous return visit customers concerned about the use

Our company is located in Tengzhou City, Shandong Province, China.A domestic leading hydraulic machine production of the Holy Land.Completely dependent on first-class production process,stand out from a large number of hydraulic machine manufacturers .Over the years, widely praised by customers at home and abroad. We have a number of innovative patents,because more than ten years to concentrate on only hydraulic press forklift tire press machine,in the small and medium enterprises has been the leader of the brand.

Address:

No.219,Xingye North Road,Economic Development Area,Tengzhou City,Shandong Province

We Recommend

New Arrivals

New products from manufacturers at wholesale prices