rubber playground surface outdoor play area flooring garden safety mats | Made In Malaysia

- Category: >>>

- Supplier: PSF INDUSTRIES SDN. BHD.PSF BHD.

Share on (62000964901):

Product Overview

Description

Square Rubber Tiles for Playground

Rubber playground surface for outdoor play area flooring or as garden safety mats are widely used. Available from 20 to 125mm thickness & with different backing profile, Prime Play tiles are one of the best option available worldwide for play flooring. Safety is our main concern & we develop all the play flooring option with care.

Widely used in children playground, outdoor fitness areas, paver, landscape flooring, gym flooring, patio, outdoor flooring etc.

Benefits

- Resilience

- Shock-proofing

- Anti-slip, anti-static

- Abrasion-resistance

- Corrosion-resistance

- Noise-absorbing

- Oxidation-resistance

- Durable

- UV-resistance ( special UV treatment available )

- Longer lifespan.

- Perfect Safety performance , fall height damage can be reduced to minimum.

- Non-toxic, in accord with environmental protection, health requirements.

- Easy to clean, clean with water or mild detergent.

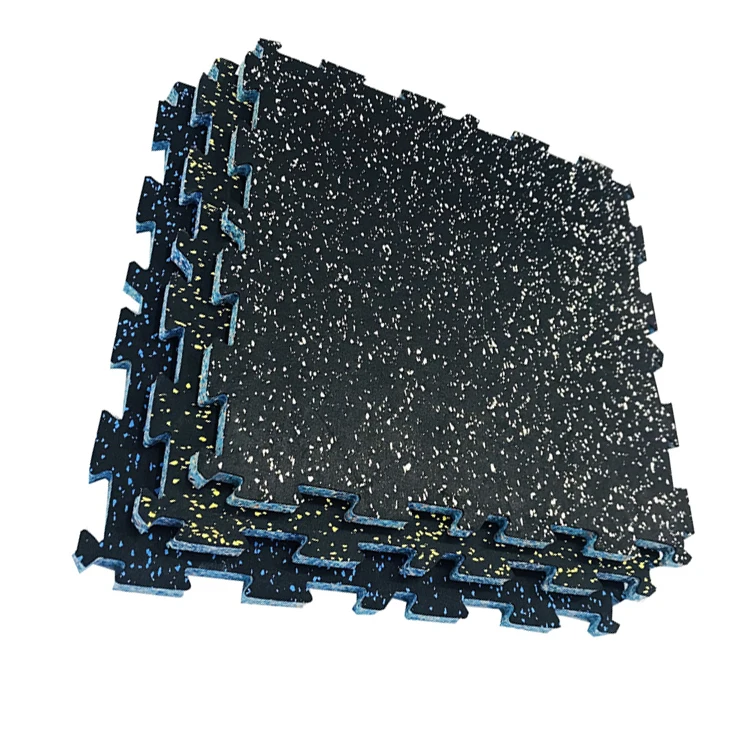

- Laid easily and quickly. Available for adhesive laid, can be directly laid with connecting interlocking pin.

Product Application

- Children playgrounds

- Outdoor Fitness flooring

- Gym Flooring

- nursing homes

- Paver

- Patio

- Landscape flooring

- Swimming pool surrounded flooring

- Industrial floor

- armed police actual combat training venues, etc.

| Grade | SBR Safety Recycled Rubber Tiles |

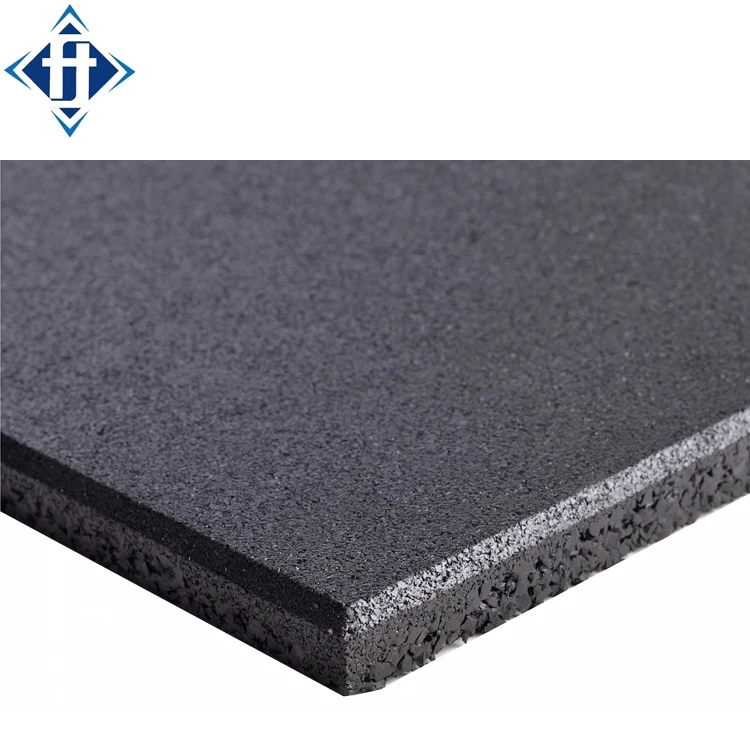

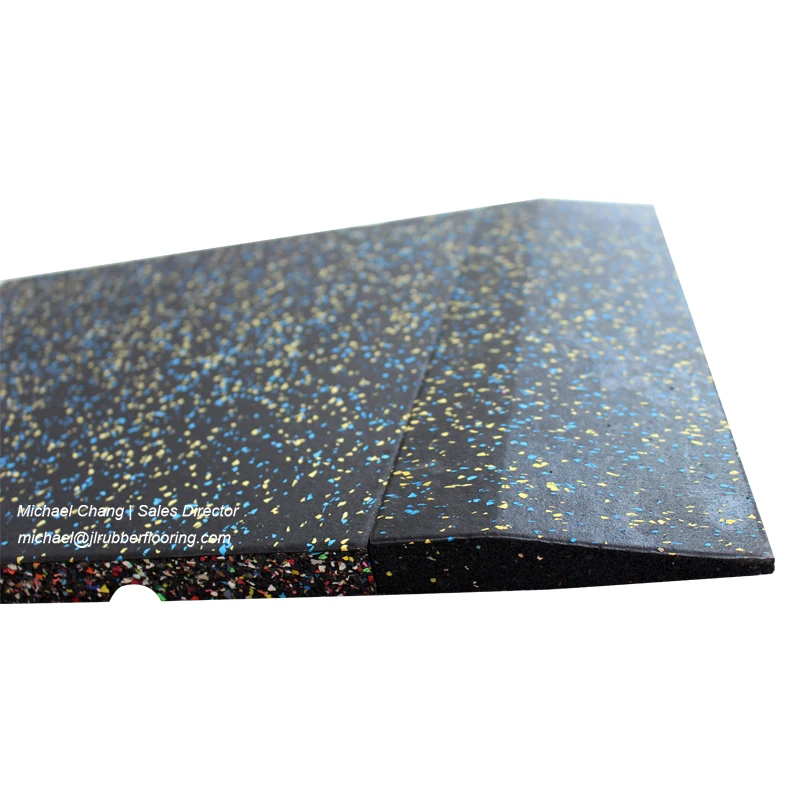

| Materials | Top Layer - 7-10mm thick of SBR Rubber with fine rubber granule Bottom Layer - SBR coarser rubber granules |

| Colour | Pigmented Series, Speckled Series, Top EPDM Series |

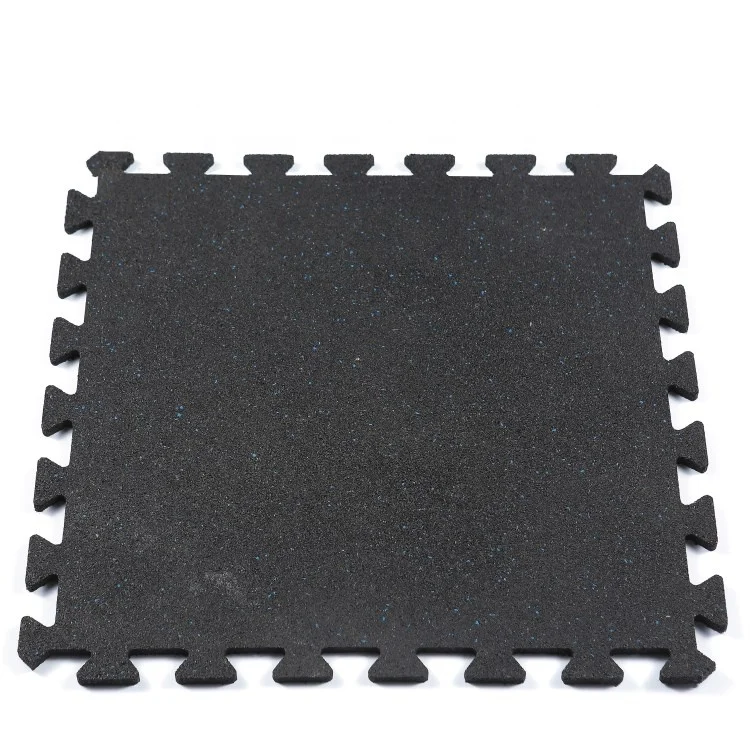

| Shape | Square |

| Backing Profile | Flat, ST, KH, Custom Made etc. |

| Method | Both bonded & moulded with MDI based binder |

| Dimension (mm) | 1000x1000mm, 500x500mm, 400x400mm (custom made) |

Q1. What is your MOQ for Rubber Tile?

A: Usually our MOQ is 200 Square Meters, but We accept your trail for lower Quantity Orders. Please feel free to send inquiry to us.

Q2. Can I get a samples of Rubber Tile?

A: Sure We can provide for existing Sample for checking quality, and it is for FREE!.

Q3. What is your Production Lead time?

A: It takes up about 15-40 days depends on the Quantity Order.

Q4. How can I check the quality on the Rubber Tile?

A: We can send a Sample & you can check the quality of the Product.

Q5. Are these Rubber Tile safe for the environment?

A: Yes. These tiles are manufactured with strict precautions to protect the environment. We only best quality materials as per international standard & requirements.

Q6: What are the methods of payment?

A: We prefer that we receive Telegraphic Transfer (TT) as payment method. We also accept LC at sight with accordance to certain conditions.

Q7. How can I be sure of your credibility as a seller?

A: We’ve been in business for a long time. We gained to our Customer’s such Trust and Confidence. You are always welcome to visit us.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices