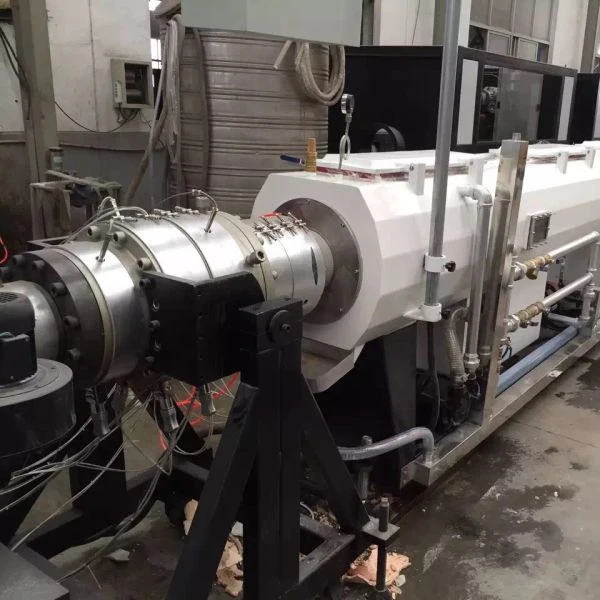

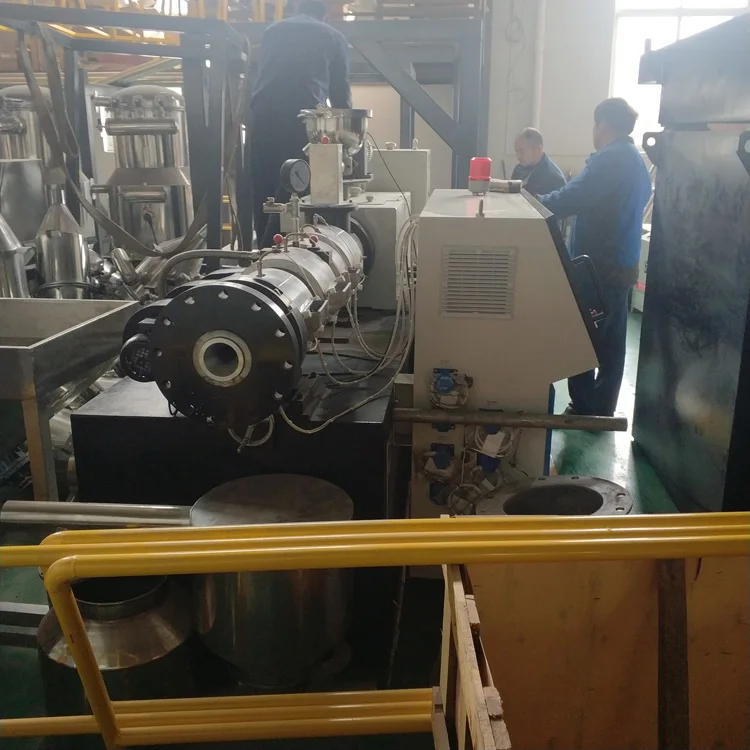

plastic twin screw extruder machine

- Category: >>>

- Supplier: Zhangjiagang Bestec Machinery Co. Ltd. [Jiangsu Province China]Zhangjiagang

Share on (62040581500):

Product Overview

Description

plastic twin screw extruder machine

Description for pe pipe production machine

This pe pipe extrusion line can be used in HDPE Large Diameter Gas and Water Pipe which have excellent stiffness and flexibility, heat resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep deformation, heat-linkage, and so on. So, this pipe production line is a preferred gas and water pipe for ductwork system between city and its suburb, Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

The complete extrusion consists of following items:

l. Single screw extruder

2.Co- extruder: to manufacture marking multi-layers of pipe

3. Die head

4. Vacuum tank: due to diameter, it can be designing of single, double vacuum chambers

5. Cooling tank: due to diameter, the numbers of cooling tanks can be one or two

6. Haul-offs: due to diameter, it can be designing of double or three caterpillars

7.Cutter: no scraps cutter.

8. stacker

|

Item | SJGF110 | SJGF250 | SJGF400 | SJGF630 | SJGF800 | SJGF1000 | SJGF1200 |

Dia.(mm) | 20-110 | 110-250 | 250-400 | 400-630 | 630-800 | 500-1000 | 630-1200 |

Main machine | SJ25/25 SJ65/33 | SJ25/25 SJ75/33 | SJ25/25 SJ90/33 | SJ25/25 SJ120/33 | SJ150/33 | SJ150/33 | SJ90/33 SJ120/33 |

Max. capacity (kg/h) | 80-160 | 200-350 | 400-600 | 700-900 | 900-1200 | 900-1200 | 900-1400 |

Total power (KW) | 110 | 260 | 400 | 500 | 600 | 600 | 900 |

The sample service

1. We can send you the video of the running machine.

2. You are welcome to come to visit our factory,and see the machines running.

3.If we get the permission of the customers who have bought the machines from us,we can provide you their contact information and you can go and visit.

Customized service

1.We will give our professional suggestions and factory layout design according your

situation: the workshop area,material,power,filling type,the kinds of the bottles and so on.

2.We provide turn-key project .

Installation service

We will send our engineers to your factory to help you installing the machines and also train your staff until they can operate the machine well.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensure the machine running smoothly.

After-sales service

1. We provide one year warranty for machines.

2 .24x7 hours technical support for life-long

3. All needed wearing parts or maintenance spare parts after warranty time will only need our production cost and will deliver to you in 7 days by courier.

4.Our business information will be confidential to any third party unless you permit .

We Recommend

New Arrivals

New products from manufacturers at wholesale prices