Explosion proof 22kw pin type horizontal bead mill for paste in chemical industrial

- Category: >>>

- Supplier: Jiangyin Ida Equipment Co. Ltd.

Share on (62089708944):

Product Overview

Description

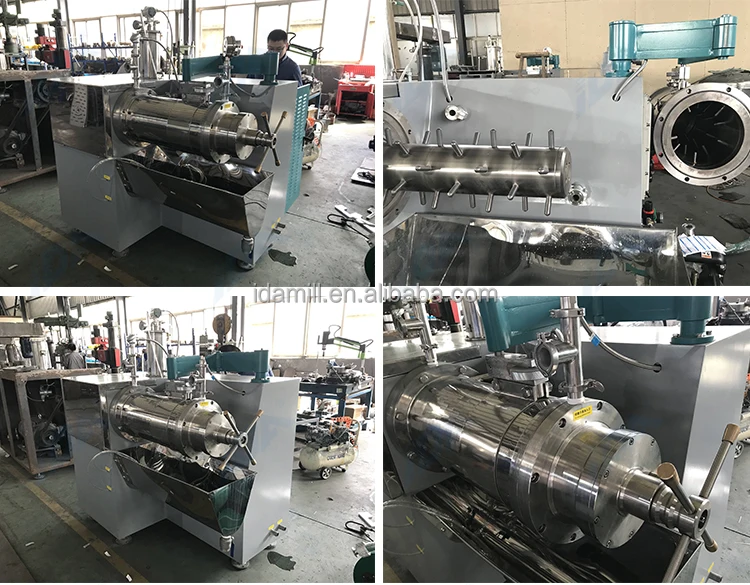

The machine adopts double-acting mechanical sealing with reliability and durability, mated with the Cooling liquid compatible to the ground material in order to reduce the pollution of ground material, suitable for grinding materials in coating, oil painting,printing ink and pesticide industries. It makes the material into aggressiveness and give the strong grind so that the grains reaches the required fineness in short time.The machine is easily operated with reliability and high production efficiency.

Depending to different requirements, the different models of machines can satisfy with customers.

Working principle

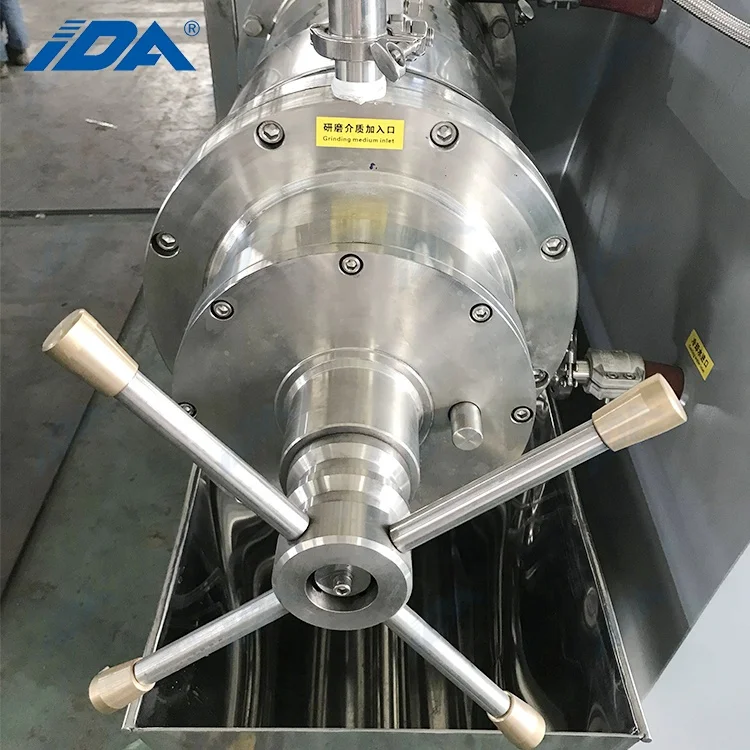

Main motor drives the main shaft to operate at high speed. The disc rotor under the high speed rotation will take the grinding media to move at high speed and form strong impact, abrasion and shear force to the materia. Under the function of strong shearing force, the large particle size material will be sufficiently dispersed and ground.The equipment has adopted reliable mechanical sealing with long durability. Grinding chamber is entirely closed, avoiding the air to come inside the chamber, preventing generation of bubbles and volatilization. It adopts the static centrifugal screen design, grinding media could not stuck in screen gap, no materlal stuck and long service life.

| Type | IBS-6 | IBS-10 | IBS-15 | IBS-20 | IBS-30 | IBS-60 | IBS-90 | IBS-150 | IBS-300 |

| Vessel capacity L | 6 | 10 | 15 | 20 | 30 | 60 | 90 | 150 | 300 |

| Main motor power kw | 7.5-15 | 18.5-22 | 18.5-22 | 22-30 | 45 | 75-90 | 110-132 | 160-185 | 250-315 |

| Grinding media mm | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 | 0.8-1.2 |

| Weight kg | 600 | 750 | 1300 | 1300 | 1500 | 3000 | 4000 | 6000 | 7500 |

| Configuration table | |

| Explosion-proof | |

| Cylinder | 304 Stainless steel passivation |

| A3 carbon steel with paint | |

| Material of Cylinder liner | Ceramic |

| Die steel | |

| Pump | Gear pump |

| Diaphragm pump | |

|

Hose pump |

|

| PLC | Siemens |

| Domestic | |

| Inverter control | ABB |

| Domestic | |

| Auxiliary cooling system | |

| Feed filter | |

| Discharge fliter | |

Hot selling