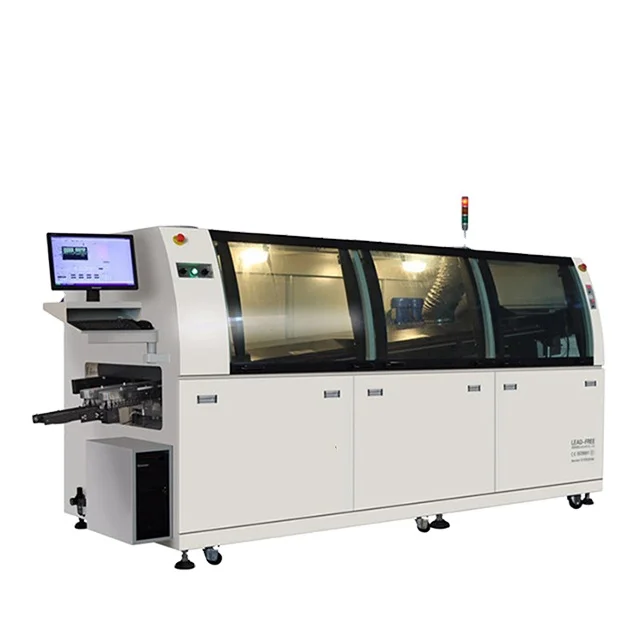

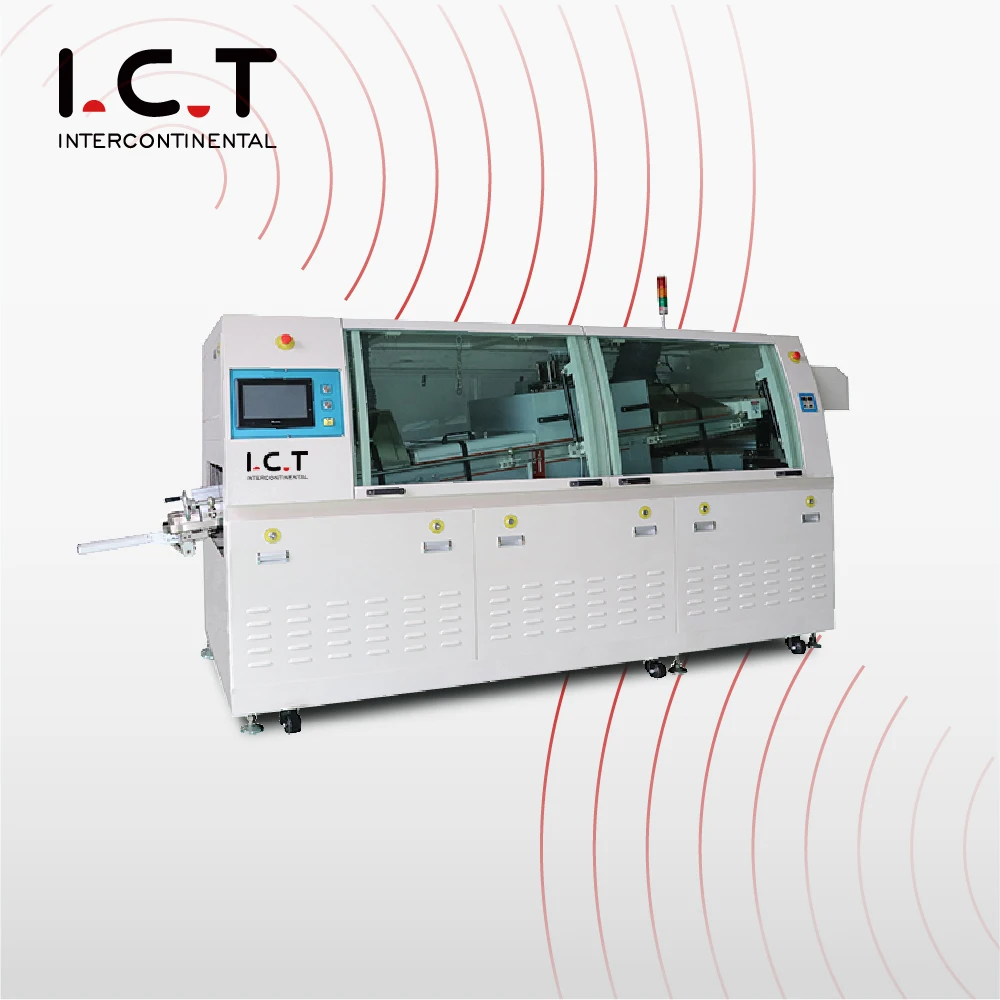

Welding Machine Wave Soldering Machine for PCB Assembly Line Production/wave Solder Machine Provided 220V

- Category: >>>

- Supplier: Shenzhen Shengdian Electronic Equipment Co. Ltd.Shenzhen Ltd.

Share on (62106238051):

Product Overview

Description

Wave soldering SD-300 series parameters

Features:

- Appearance streamlined design, internal modular design, suitable for SMT and straight element lead-free welding.

- The spray system uses a centrifugal fan to prevent the flux from dripping on the PCB.

- Fluder buffer tank sensor external, more reliable and durable.

- Standard cold air knife to prevent flux fog spread outward, reduce pollution.

- Double-wave control adopts the infinite frequency conversion technology, which can control the wave peak height independently.

- 1 / 4HP high power peak motor, maximum peak height up to 15mm.

- With overtemperature sound and light alarm and emergency braking system, all motors have overload guarantee.

- The transportation system adopts infinite electronic adjustment and closed-loop control, with stable and accurate speed.

- Pressure assist device is provided at the inlet end to avoid slipping when the PCB enters.

- The forced natural cooling system can meet the cooling slope requirements of lead-free process.

- The track angle is manually adjusted for easy operation.

- The flux nozzle is driven by a stepper motor to ensure uniform flux coating.

- The modular design of the spray system, the nozzle is always vertical track to ensure good penetration of PCB.

- The preheating zone uses hot air heating, the whole process of high temperature, glass protection, temperature stability.

- The preheating system is controlled by PID, and the temperature curve is stable, which is convenient to find the best setting for various lead-free processes

| Complete Machine Technical Parameters | |

| PCB adjustable width | Max.50-300mm |

| PCB transport height | 750±50mm |

| PCB transport speed | 0-2.0M/Min |

| PCB transport Angle (welding inclination) | 3-7 Degrees |

| PCB transport direction | L→R/R→L(optional) |

| Component height limit on PCB board | Max.80mm |

| Length of preheating zone | 1200m |

| Number of preheating zone | 3 segments |

| Preheating zone power | 9.0KW |

| Preheating zone temperature | Room temperature of ~120ºC can be set up |

| Heating method | Hot air 120 high temperature motor |

| Number of cooling zone | 1 pcs |

| Cooling-down method | Axial flow fan cooling |

| Solder type | Lead-free solder / regular solder |

| Tin furnace power | 10KW |

| Tin furnace dissolved tin amount | Approx.280KG-300KG |

| Tin furnace temperature | Room temperature ~300ºC, control accuracy ± 1ºC |

| Temperature control mode | P.I.D+SSR |

| Control mode of complete machine | Siemens PLC + Siemens temperature module control |

| Flux capacity | Max5.2L |

| Flux flow rate | 10-100ml/min |

| Spraying mode | Stepper driver and stepper motor + Taiwan qibao nozzle |

| Power supply | A 3-phase 5-wire system of 380V |

| Start up power | Max. 10KW |

| Power for operation | Approx.6-8kw |

| Air source | 4~7KG/CM² |

| Frame size | L3000×W1200×H1650MM |

| Dimensions | L3600×W1300×H1650MM |

| Weight | Approx.1000kg |

| Spray nozzle moving system | Driven by stepper motor, the moving speed is average, stable and reliable |

| Temperature control mode | Siemens temperature acquisition module, PID temperature control is accurate and reliable, imported thermocouple detection system, with thermocouple abnormal alarm function. |

| Adjustment mode | Manual adjustment |

Company Information

Professional SMT Equipment Manufacturer

Shenzhen Shengdian Electronic Equipment Conmpany is a professional manufacturer of SMT

Equipments with more than 10 year' experience. We have served many factories,and we will

customize their SMT solutions according to customers' different products,capacity,number of

employees,and financial status. According to whether your universal production line needs more

sophisticated testing equipment,there are AOI,SPI,FAI to option.

Manufacturing Shop

SD One-stop SMT Solution Supplier

Production Details

Technical Team

Packaging & Shipping

Shipping Methods

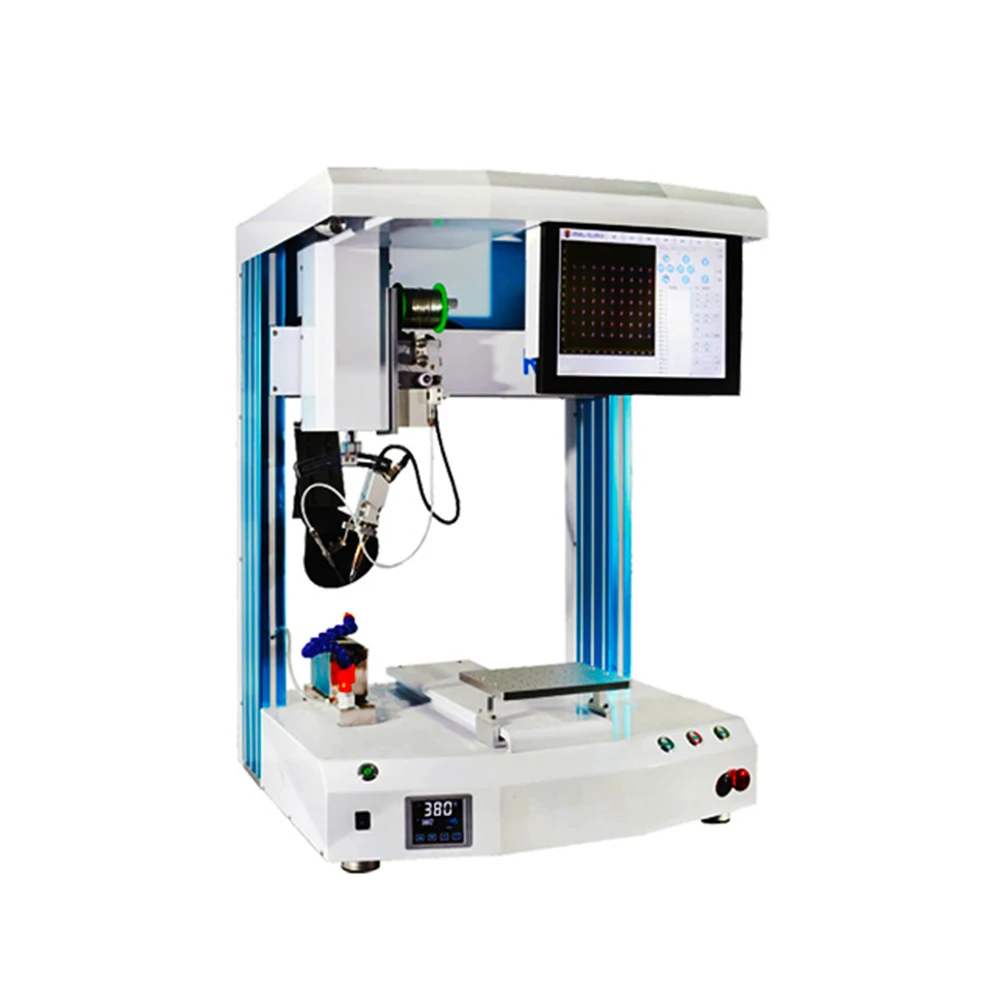

We Recommend

New Arrivals

New products from manufacturers at wholesale prices