High competitive high stable PP/PE/PPR pipe extrusion machine produced in China

- Category: >>>

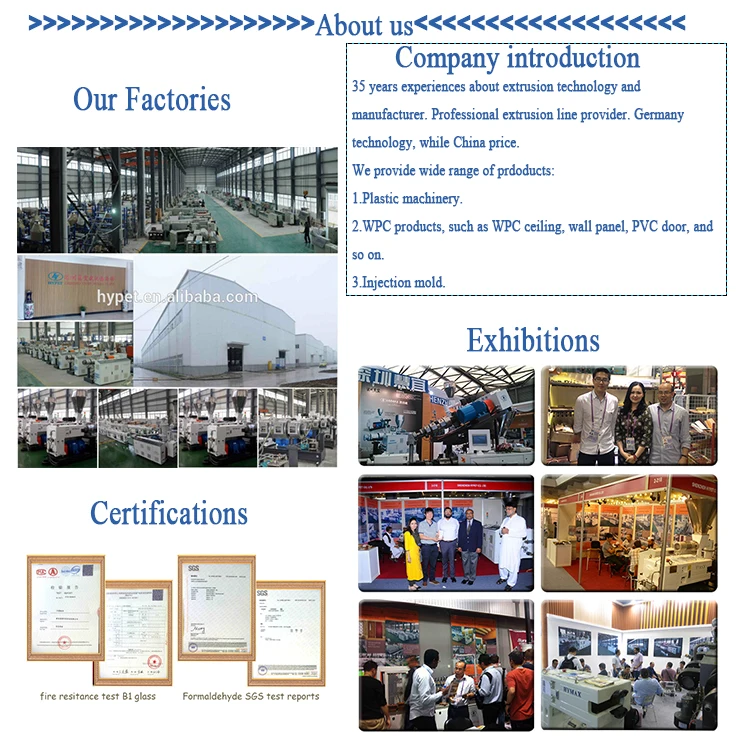

- Supplier: Shenzhen HYPET Co. Ltd.

Share on (62121490296):

Product Overview

Description

High competitive high stable PP/PE/PPR pipe extrusion machine produced in China

Product Description

| Item Name | High competitive high stable PP/PE/PPR pipe extrusion machine produced in China |

| Brand Name | HYPET |

| Extruder Model | HYSJ100/38 |

| Power | 220kw |

| Plastic progressed | PE pellets |

| Max output | 850kg/h for PE pipe |

| Pipe diameter | 160~500mm PE pipe |

| Screw desigh | Single-screw |

| Automatic Grade | Full Automatic |

| Voltage | 380V 50HZ 3Phase / Optional |

| Dimension | 38m*2.0m*2.5m |

| Weight | 30-40T |

| Certification | CE,ISO9001 |

| Motor brand | Siemens |

| Warranty | 24 Months |

| Payment | T/T and L/C (irrevocable, at sight) both are acceptable. |

Brief Intruduction

This line is designed to produce PE/HDPE pipe, with HYPET high-efficiency single screw extruder, the structurer of the screw forour extruder improved after repeated experimental tests, chieve maximum production while ensuring the plasticizing effect of the pipe.

It is mainly used for make various PE/HDPE pipes, can match different configurations of auxiliary machines.

Production Line Structure

Feeding→High-efficiency single screw extruder & Co-extruder→Die head→Vaccum tank→Cooling tank→Haul off unit→Cutter→Winder

Why Choose Us

- More than 30 years extrusion experience, also with international technical exchange

- HYPET has cultivated a team of highly professional engineers

- Based in the birthplace in the counter rotating twin screw extruder, and all nucleus components are made in house

- State of art design, process and application experience for parrallel and conic twin screw extruder gear box

- Suitable design for different material, based on vast practical experience

- HYPET hase set up separate laboratory with top equipments

- Extrusion performances and capacity are proved by trail commissioning

- Capable of providing tailer made solution for customers

- Capable of providing on site technical training

- Unique design, same line, different products

- Also provide various down streams and auxiliary machines for pipe, profile and WPC

We Recommend

New Arrivals

New products from manufacturers at wholesale prices