converting machine toilet paper tissue mini hemp pulp bamboo tissue toilet paper making machine

- Category: >>>

- Supplier: Qinyang City Shunfu Paper Making Machinery Co. Ltd.

Share on (62185531926):

Product Overview

Description

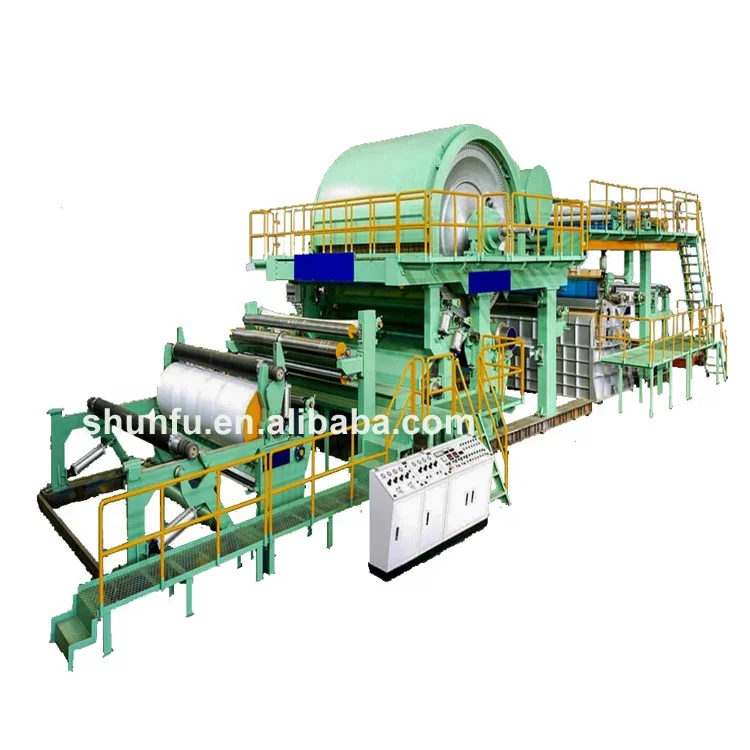

Converting Machine Toilet Paper Tissue Mini Hemp Pulp Bamboo Tissue Toilet Paper Making Machine Configuration | ||||||||||

Paper Machine Model | SF-787 | SF-1092 | SF-1575 | SF-1880 | SF-2400 | |||||

Outpaper width(mm) | 787-900 | 1200 | 1750 | 1880-2000 | 2400 | |||||

Gauge(mm) | 1300 | 1800 | 2400 | 2800 | 3400 | |||||

Machine Capacity(T/D) | 0.8-1 | 1.5-3 | 3-5 | 5-7 | 6-8 | |||||

Cylinder mold specification(mm) | φ 700*1100 | φ1000- 1250*1450 | φ1250-1500*1950 | Compression Type: Pneumatic Compression | ||||||

Dryer specification(mm) | φ1000*1100 | φ1500-2500*1450 | φ1500-3000*2000 | / | ||||||

Work speed(m/min) | 20-40 | 20-80 | 100-150 | 100-180 | 150-200 | |||||

Raw material | Waste paper ;Vigin Pulp Board;Waste paper &Vigin Pulp Board Mixed | |||||||||

Output paper style | Jumbo Roll Paper | |||||||||

Paper weight | 15-40g/m2 | |||||||||

Drive mode | Reduce drive(250type reducer) | |||||||||

Warranty | 12 months | |||||||||

Time of delivery | 15-30days | |||||||||

Converting Machine Toilet Paper Tissue Mini Hemp Pulp Bamboo Tissue Toilet Paper Making Machine

Shows :

↑↑↑Click the process to watch the video↑↑↑

Product Feature

1) Reliable quality, stable performance, convenient operation, energy conservation, environmental protection

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) It is made up of molding, drying, transmission, pressing, walking platform and reeling parts.

4) Running in a high automatization and intellectualization.

5) Computer PLC control system with easy operation

Main Parts For Paper Machine

Raw materials for paper pulps as following

Finished Paper For Paper Machine

The finished paper product is made by the following flows:

The Material-----Paper Pulps Making Mchine----Paper Making Machine-----

---Paper Converting Machine-------Finished Paper Product

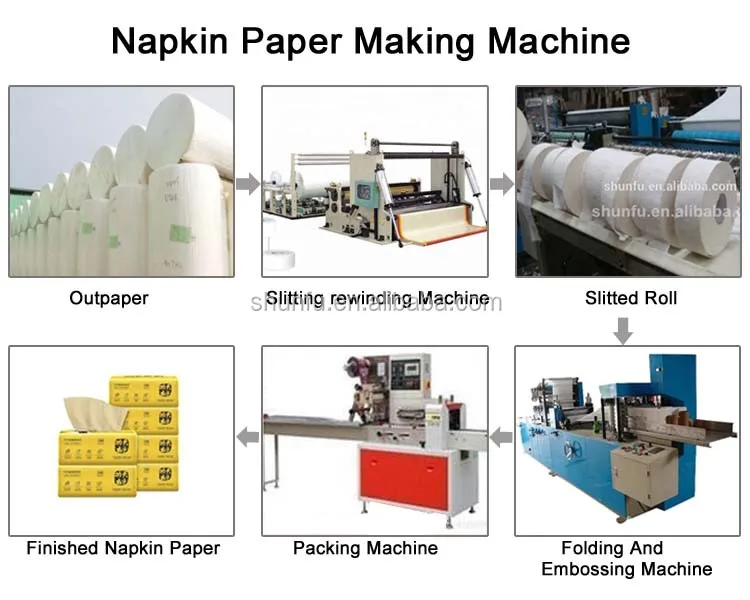

PAPER CONVERTING PRODUCTION LINE

1.Toilet roll paper machine

·Put the jumbo roll paper produced from paper machine to convey into toilet paper rewinding machine

·Then to process into band-saw cutting machine to produce small toilet roll

·Finally put the small toilet roll into plastic bag and sealed by sealing machine

·Put the jumbo roll paper produced from paper machine convey into slitting and rewinding machine to cut well rolled paper

·Then to print,emboss and automatically fold the rolled paper which is cut well into square or rectangular napkin paper

·Finally put napkin paper into napkin paper packing machine to pack into soft packed drawing napkin paper

3.Facial tissue paper machine

·Put the jumbo roll paper produced from paper machine convey into tissue paper machine to produce

·Then cut well into square or rectangular napkin paper through tissue cutting machine

·Finally put tissue paper into tissue paper packing machine to pack into soft packed drawing tissue paper

Company Introduction

Our mission is to provide you with the paper making machine that sells your product. by focusing on product knowledge custom machine solution and the know-how, we will build life long relationships.

Our Customers' Highly Appraised for our company and products