Qiaoxin tungsten wire heater element for hot sale

- Category: >>>

- Supplier: Shanghai Qiaoxin Industry Co. Ltd.

Share on (62226400885):

Product Overview

Description

Qiaoxin tungsten wire heater element for hot sale

Product details

| Surface: | black, alkali washing |

| Purity: | 99.95% |

| Material: | W1 W2 |

| Certificate: | ISO 9001 Ro HS SGS |

| Density: | 19.3g/cm3 |

| Application: | industrial |

| Melting Point: | 3620 |

| Product Keywords | tungsten wire saw,tungsten wire rope,tungsten wire mesh heater element |

Product Details:

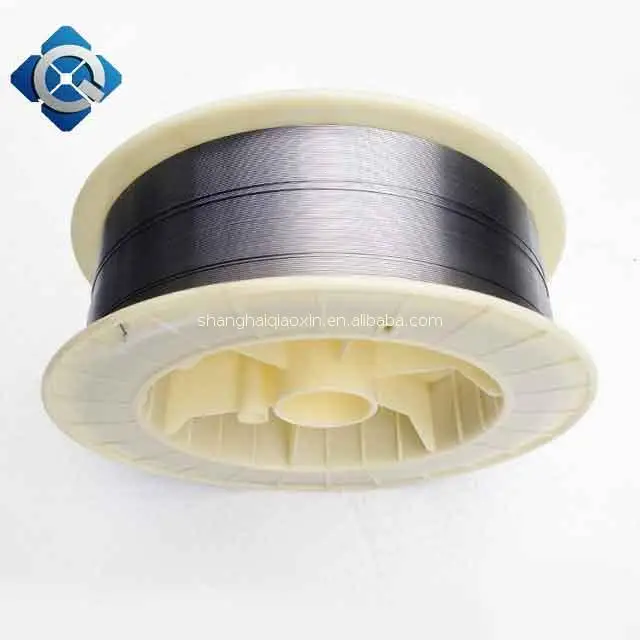

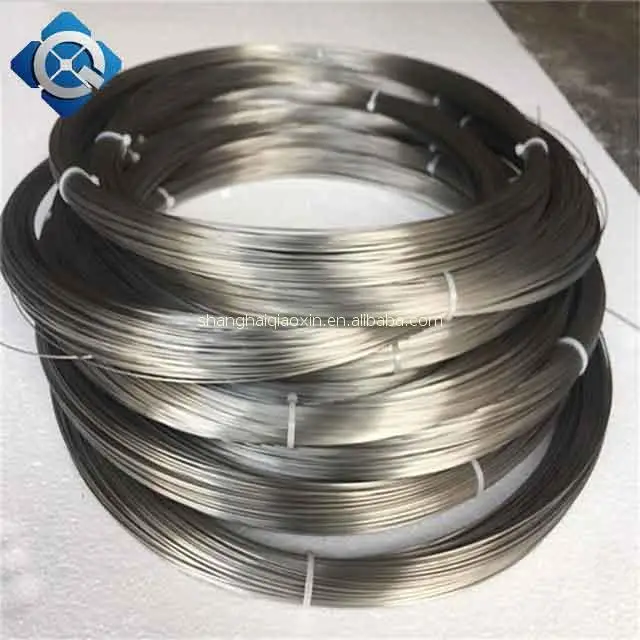

| Product Name: | Tungsten Wire |

| purity: | 99.95% |

| Grade: | W1,W2 |

| Appearance: | Regular black covered with graphite. After graphite is removed it is metallic luster |

| Application: | 1,producing electric light source parts and electri c vaccum components. 2,producing heating elements and refractory par ts in high temperature furnaces. 3,producing heating elements used in vaccum m etalizing or plating. |

Chemical components:

| Designation | Tungsten Element(%) | Impurity Element | |

| Total(%) | Each(%) | ||

| WAL1,WAL2 | ≥99.95 | ≤0.05 | ≤0.01 |

| W1 | ≥99.95 | ≤0.05 | ≤0.01 |

| W2 | ≥99.92 | ≤0.08 | ≤0.01 |

Note: Potassium is not counted in impurities content.

Diameter Tolerance:

| Diametert(um) | Weight(mg/200mm) | Weight(mg/200mm) Tolerance(%) | Diameter Tolerance(%) | ||||

| Grade0 | Grade1 | Grade2 | Grade0 | Grade1 | Grade2 | ||

| 5≤d≤12 | 0.075~0.44 | - | ±4 | ±5 | - | - | - |

| 12<d≤18 | >0.44~0.98 | - | ±3 | ±4 | - | - | - |

| 18<d≤40 | >0.98~4.85 | ±2 | ±2.5 | ±3 | - | - | - |

| 40<d≤80 | >4.85~19.39 | ±1.5 | ±2.0 | ±2.5 | - | - | - |

| 80<d≤300 | >19.39~272.71 | ±1.0 | ±1.5 | ±2.0 | - | - | - |

| 300<d≤350 | >272.71~371.7 | - | ±1.0 | ±1.5 | - | - | - |

| 350<d≤500 | - | - | ±1.5 | ±2.0 | ±2.5 | ||

| 500<d≤1800 | - | - | ±1.0 | ±1.5 | ±2.0 | ||

ABOUT US

CUITURE

We cooperate with more than 30 domestic factories, straight for the products for us.Our cooperation factory has more than 15 years experience in production technology .We mainly operate metallic titanium and titanium alloy materials. We are a professional manufacturer for processing and producing metallic titanium, as well as titanium alloy materials. We are known for advanced processing technology, strong technical force, excellent quality, prompt delivery, and high credibility. We have complete production lines of bar materials: forging, rolling, grinding, and machining. We are able to achieve large-scale production of different thicknesses, different scales, different varieties and different specifications for different requirements of bars. We are able to use different classifications for production process.

PACKAGE:

Standard export carton packing or as according to customer`s requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices