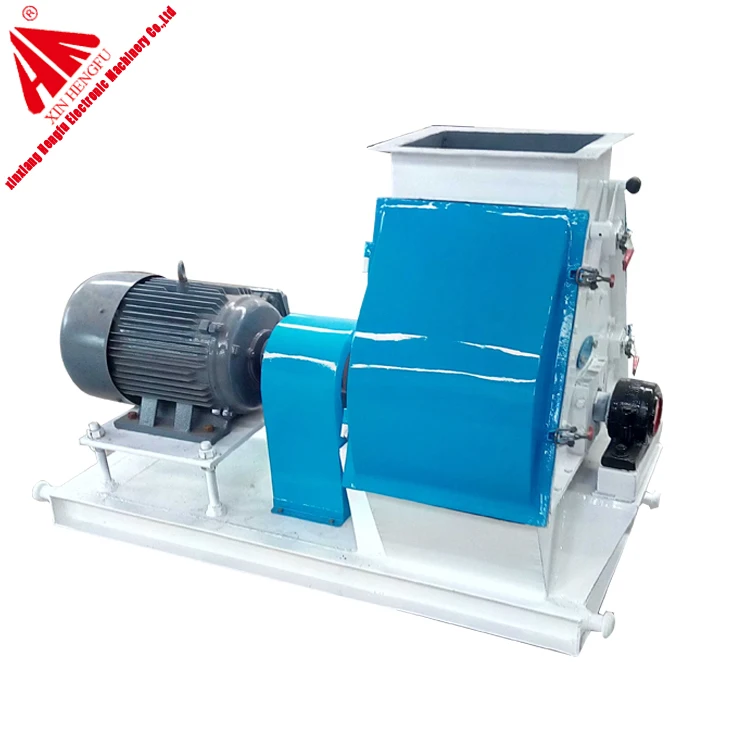

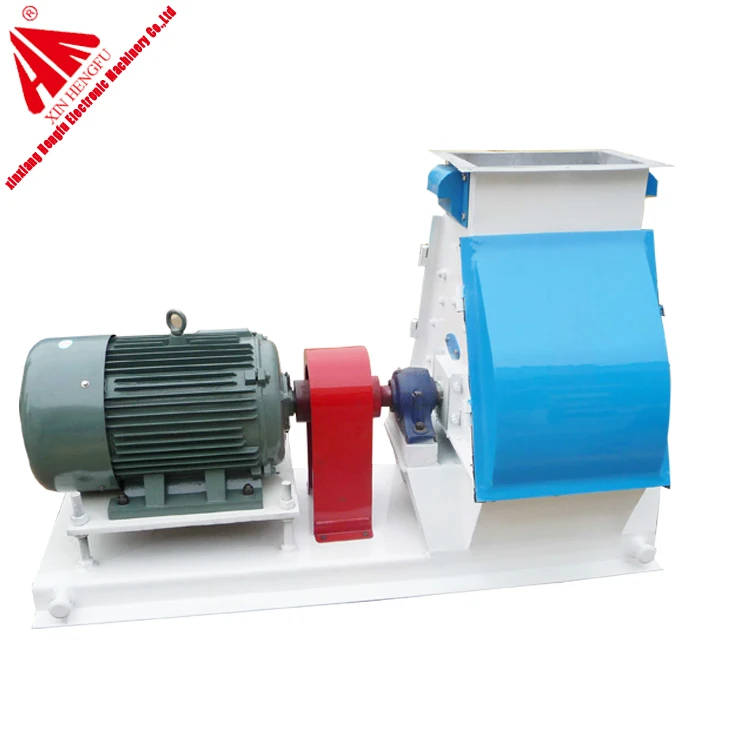

Small Poultry Feed Milll/corn grains water drop hammer mill/Poultry Feed Grinding Machine

- Category: >>>

- Supplier: Henan Hengfu Machinery Equipment Co. Ltd.

Share on (62270465023):

Product Overview

Description

Small Poultry Feed Milll/corn grains water-drop hammer mill/Poultry Feed Grinding Machine

Characteristic of Maize Grinding Hammer Mill

1. crush room at bottom of the use of two-hit designed to increase production by more than 15%, to crush a more uniform size.

2. room for the water drop hammer mill,to elimination of circulation and increase output

3. through the adjustment of screener space,to achieve coarse or fine crush,so live up to a dual-purpose machine

4. mill rotor balancing by check,equipment operation less vibration,less noise,more stable

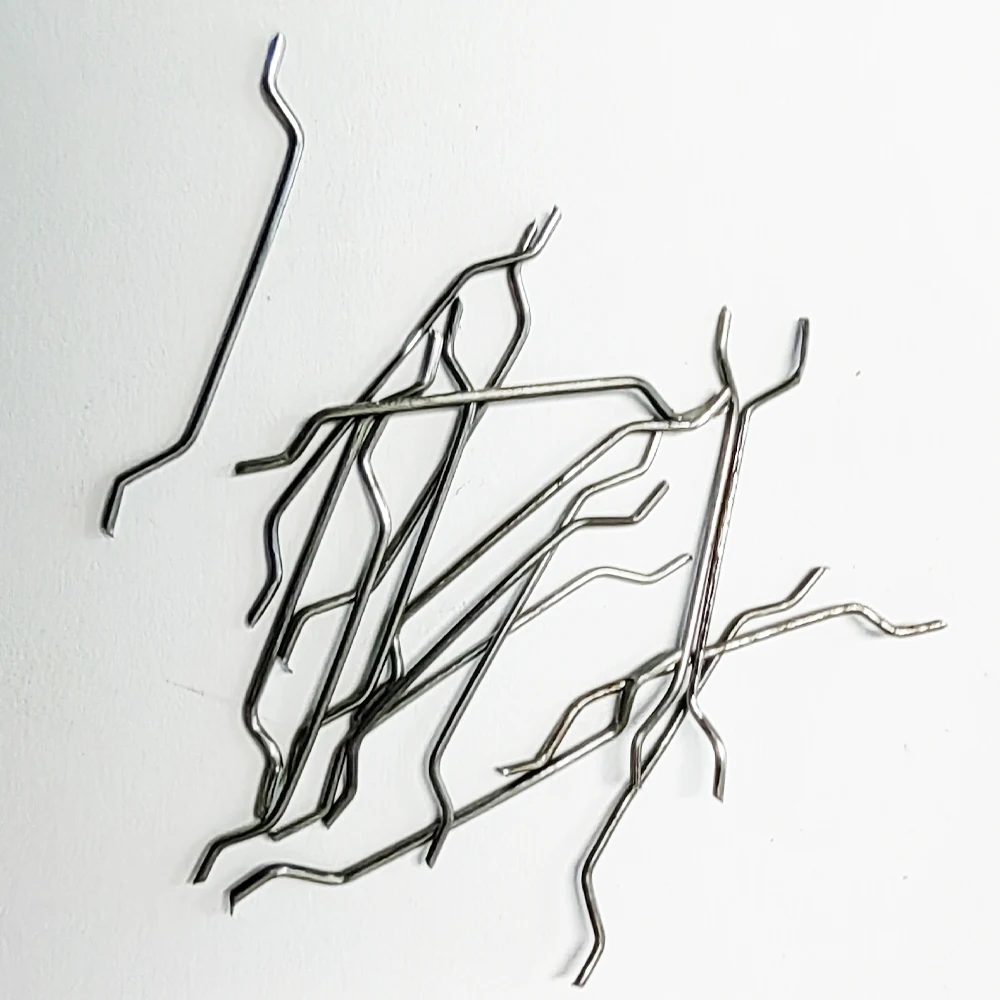

5. vacuum melting and hardening the surface of hammer pin,plate with high-quality carbon structural steel manufacturing,to extend the service life,reduce the consumption of parts

6. direct drive,a new snake-coupling spring,compensation,to avoid bearing have a fever

7. adopt of imported high-quality bearings,long life and smooth operation

8. impeller feeder equipped with feed conversion and screw conveyor feed speed and other forms

1.The SFSP56*36 Main Parameter

1.CAPACITY(T/H) | 1--3 |

2.POWER(kw) | 22 |

3.VOLTAGE | 380V,50HZ,3phase |

4 DIAMETER OF HAMMER ROTOR | 180 |

5.VALIDITY | One year |

6.HAMMER QUANTITY | 40 |

7.COMPANY | LXT |

8.DIMENSION(mm) | 1430*700*1000 |

9.CERTIFICATION | ISO,9001,CE |

2.The SFSP Series

Model | SESP56*36 | SFSP56*40 | SFSP708*40 |

Rotor diameter(mm) | 560mm | 560mm | 708mm |

Crush room width(mm) | 360mm | 400mm | 400mm |

Rotate Speed(r/min) | 2900 | 2900 | 2900 |

Number of Hammers | 40 | 40 | 40 |

Capacity(t/h) | 1-3 | 2-5 | 3-8 |

Main Power(kw) | 22 | 37 | 55 |

Weight(kg) | 800 | 920 | 1600 |

Dimension(L*W*H) | 1430*700*1000mm | 1500*700*1000mm | 1850*750*1250mm |

Pre-sale service:

1.Provide our client with investment guide for free.

2.Provide our client with evaluation investment scheme for free

3.Free visit to our factory.

4.Design of production line scheme is provided for free.

In-sale service:

1. Experienced workers are sent to provide track service when equipment is transported.

2. Experienced technicians or engineers will be sent for on-site installation, adjustment and technical devices according to clients' engineering requirement.

3. "Operating instruction manual", equipment assembly drawings and wearing parts list in duplicate will be provided for free.

Post-sale service:

1. On the premise that equipment is operated correctly and in warranty period, we accept repair, exchange, and return items.

2. We provide permanent favorable spare parts for our clients.

3. We provide permanent technology support and related help.

² Professional engineering design

² Earliest delivery ,high quality with best price

² Safe and efficient transport services

² Efficient installation guide can send video installation and operation

² One year guarantee for whole machine, except the wearing parts .

² We can provide engineers available to service machinery overseas.

² 24 hours technical support by E-mail or telephone.

With More than 25 Years in Production of Animal Feed Machines

Xinxiang Hengfu Electronic Machinery Co. Ltd, founded in 1993, is currently one of the best key enterprises specialized in the research and development of feed machinery, pellet machines, animal feed mixers and grinders in the machinery manufacturing industry, which have passed the certification of CE due to our ISO 9001:2008-certified operations. Our feed complete equipment have been exported to North and South America, Africa, Asia, Europe, and more than 20 countries worldwide. We also have strict and complete QC system.

Good quality, competitive price and excellent after-sale service are highly praised by customers. So far, product sales have covered more than 25 provinces and cities in China and also exported to Ghana, Botswana, Benin, Ivory Coast, Venezuela, Mozambique, Indonesia, Malaysia, Korea and over more than 20 countries.

To give you the accurate price, there are some details to confirm as follows:

1. What's your raw material?

2. what kind of animal do you feed?

3. The output per hour?

4. Do you also need automatic packing machine?

5. The basic processing technology: Grinding, mixing, pelleting, cooling, crumbling, screeening, packing. Any special requirement, let me know directly.

6. Our normal voltage is 380V, 50HZ,3phase, if yours is different, tell me yours.

1.Are you manufacturer,yes or not?

Answer:Yes. We have been feed machine manufacturer for 23 years and it will be longer.Now we are capable of producing not only feed machines but also biomass machines and mineral stone processing machines.

2.Can you accept the customized plan? Can you simplify my plan for reducing costs?

Answer:Of course,our brilliant engineers are waiting for it all the time.

3.What's your MOQ?

Answer:Generally speaking,one is okay,but larger quantity ,lower price.

4.What i need know to build a feed processing plant?

Answer:You just need figue out the following questions:

(1)What animal you want to feed? the animal amount?This is used for confirming the production capacity and feed type.

(2)What raw materials you have?material size?material moisture?

(3)Any speical demand?Wait for your contact anytime.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices