Qiaoxin hastelloy g30 254SMO plate grade UNS S31254 W.Nr.1.4547 for sale

- Category: >>>

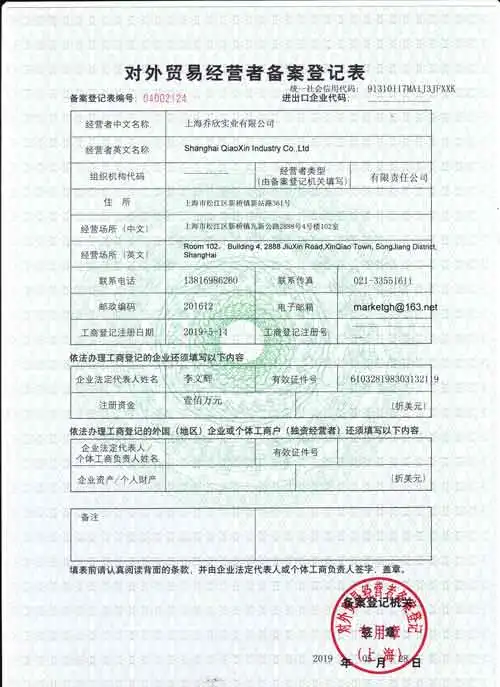

- Supplier: Shanghai Qiaoxin Industry Co. Ltd.

Share on (62275774029):

Product Overview

Description

Qiaoxin hastelloy g30 254SMO plate grade UNS S31254 W.Nr.1.4547 for sale

Product details

| Ni (Min): | 58% |

| Resistance (μ.m): | 1.5 |

| Elongation (≥ %): | 40 |

| Density: | 9.22g/cm3 |

| Melting Point: | 1370°C |

| Thickness | 0.1mm~30mm |

| Yield strength(mpa): | 293 |

| Technique: | Cold Rolled |

| Shape: | Wrie,sheet, pipe,bar |

| Condition: | soft annealed |

| Product Keywords | hastelloy alloy c276 strip,g30 plate |

Product Introduce:

Hastelloy C-276Is a nickel-containing tungsten - chromium - molybdenum alloy, very low carbon content

of silicon is considered to be a panacea corrosion-resistant alloys. The main moisture chlorine, various

oxidizing chloride, chloride salts, sulfuric acid and oxidizing salt, in a low temperature and medium temperature hydrochloric acid has very good corrosion resistance. Thus, nearly three decades, corrosion in harsh environments, such as chemical, petrochemical, flue gas desulfurization, pulp and paper, environmental protection and other industrial fields has a very wide range of applications.

Product Chemical Compisition:

| Item | HC 276 | C-22 | C-4 | B2 | B3 | N |

| C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

| Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

| Fe | 4-7 | 2-6 | ≤2 | ≤2 | ≤1.5 | ≤5 |

| P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

| S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

| Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

| Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

| Ti + Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

| Al + Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

| Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

| B | -- | -- | -- | -- | -- | ≤0.01 |

| W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

| V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

| Ni | Rest | |||||

Product Hastelloy C-276 Mechnical Propertities:

| Status | Tensile strength Rm N/mm² | Yield strength RP0.2 N/mm² | Elongation A5 % |

| Solution treatment | 690 | 283 | 40 |

Product Features:

1.Excellent corrosion resistance to most of corrosion media in oxidation and reduction environments.

2.Excellent resist pitting, crevice corrosion and stress corrosion cracking performance.

ABOUT US

CUITURE

We cooperate with more than 30 domestic factories, straight for the products for us.Our cooperation factory has more than 15 years experience in production technology .We mainly operate metallic titanium and titanium alloy materials. We are a professional manufacturer for processing and producing metallic titanium, as well as titanium alloy materials. We are known for advanced processing technology, strong technical force, excellent quality, prompt delivery, and high credibility. We have complete production lines of bar materials: forging, rolling, grinding, and machining. We are able to achieve large-scale production of different thicknesses, different scales, different varieties and different specifications for different requirements of bars. We are able to use different classifications for production process.

Company Certificate:

PACKAGE:

Standard export carton packing or as according to customer`s requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices