powerful jet spray water nozzle sprayer

- Category: >>>

- Supplier: Cixi Weiyue Metal Product Co. Ltd.Cixi Ltd.

Share on (62459323961):

Product Overview

Description

Powerful jet spray nozzle :

1) Material: solid brass

2)The thread is 3/4"-11.5NH (US) or 3/4"-14G BSPP(EU)

3)Working pressure: No more than 150PSI;

Working temperature: -20 to 120 degree Centigrade;

4)Before delivery, all the items will be strictly tested for its working pressure, leakage, surface finishing and thread test.

5) High quality , competitive price and guarantee of quick delivery.

6)The write part is made of stainless steel.

7)Convenience and speed are the major advantages. powerful jet stream sprayer really are handy and save you time and effort.

8)Adjustable spray from off fine mist to powerful jet stream.

9) All these items are produced by digital CNC machines, then the quality and precision can be ensured accordingly.

Powerful sprayer

Features:

Heavy duty and versatile fire hose style nozzle

Fits any standard garden hose

Fully adjustable from powerful stream to gentle fan

Perfect for washing any car, truck, SUV, or RV

Built with durable brass, steel, and rubber

Precision machined brass internals resist corrosion and wear

Steel reinforcements protect nozzle from crushing blows

Soft rubber grips protect sensitive surfaces from accidents

Double blisters packaging

Water spray

How To Use:

Clean hose end threads on standard garden hose by wiping out any mud, dirt, or embedded debris.

Check ozzle rear main O-ring for proper placement before screwing nozzle onto hose.

Screw Hose Nozzle onto the threaded end until it fits snugly.

Turn hose spigot open to let water flow through the garden hose.

Check for leaks and make any required adjustments.

Adjust hose nozzle to produce desired spray pattern.

Twist nozzle to full off position when finished watering, rinsing, or in between uses on a job.

Shut off hose spigot when finished with the hose.

Where To Use It

Spray bugs, tar and other stubborn stuff on vehicles. Blast through mud, dirt and debris on the surface of your vehicle, wheel wells and undercarriage.

Heavy-duty stream for washing pool decks, driveways or sidewalks to remove dirt quickly.

Wide spray to gently and thoroughly rinse of soap after washing boats, RV's or cars.

Medium spray to saturate your lawn, and cover large areas with less movement.

Please Note:

This heavy duty hose nozzle is constructed by high grade brass and stainless steel, main feature and advantage is durability, strength and unbreakable, can be used for lifetime.

The nozzle depends on your water pressure, the amount of water you can pump out, If you have a good water pressure, the nozzle will produce a very strong stream.

Who we are

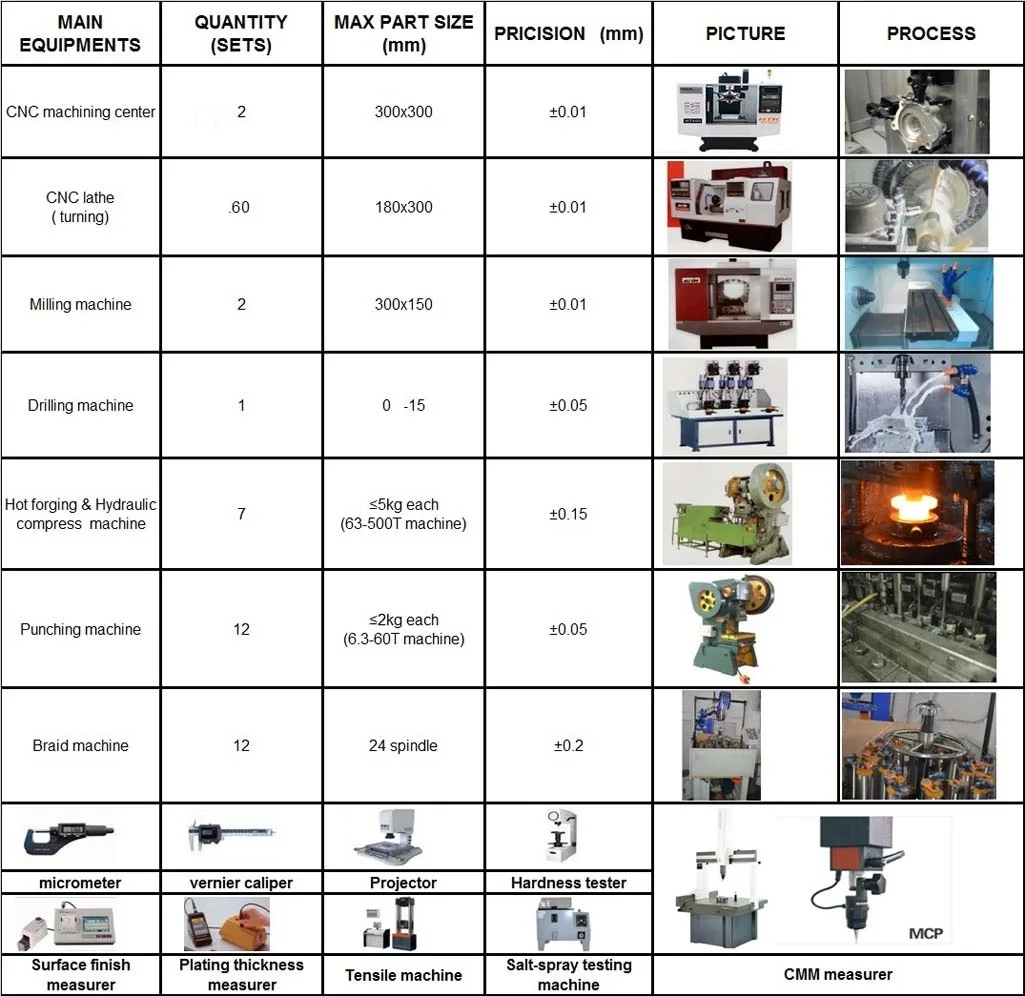

Founded in 2001,Cixi Weiyue Metal Product Co., Ltd. is a specialized provider of metal forging, machining, stamping customized parts and Stainless Steel Braided Hose. We have a complete in-house manufacturing system - from products design, making, testing, to parts processing and assembly. With over 15 years of export experience, we have established a long-term cooperation relationship with many customers in Europe, America, Middle East and South-east Asia and all over the world.

All our products are manufactured under Precision manufacturing, which have five floors of 4810 square meters. Owning various types of precision automatic equipments: 120 sets of CNC Lathe, CNC machining centers, forging and Stamping Machines, thread rolling machines and other processing machines. those have a monthly capacity of 3,000,000 units, to match your volume orders . There are also lots of testing equipment for quality assurance. Such as: three dimensional, optical Projector, Surfagauge, sclerometer, Tension tester, etc. Quality Control All of our engineers and Q/C guys concern and active in every engineering and manufacturing stages by ISO standard. Available materials: brass, mild steel, steel alloy, stainless steel and iron, aluminum, zinc; Available surface finish: fine polish, electrolyte-polish, chrome, zinc plating, nickel plating, aluminum oxidation. Available processes: metal processing includes machining, stamping, die-cast and hot-press,expert plastic injection, and surface plating.OEM orders are welcome Contact us NOW If you have new project please send your 2D or 3D drawing(STP,IGS)file to us, we will be quote to you in 24hours.

What we do

How we do Capacity

Capacity

Material Available

Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

Brass | HPb62, HPb61, HPb59, Hpb58-3, etc. |

Copper | C46500,C48600, C36000, CW617N etc. |

Aluminum | AL6061, Al6063, AL6082, AL7075, A380, ACD12 etc. |

Iron | A36, 45#, 1213, 12L14, 1215 etc. |

Surface finish:

Aluminum parts | Stainless Steel parts | Steel | Brass |

Clear Anodized | Polishing | Zinc plating | Polishing |

Color Anodized | Passivating | Oxide black | Nickel plating |

Sandblast Anodized | Sandblasting | Nickel plating | Sandblasting |

Chemical Film | Laser engraving | Chrome plating | Laser engraving |

Brushing |

| Carburized |

|

Polishing |

| Hot treatment |

|

Chroming |

| Powder Coated |

|

Shipment

1. By express: DHL, UPS, FedEx, etc. Door to Door

2. By air: Airport to Airport, Ningbo or Shanghai

3. By sea: EXW, FOB, CIF

FAQ

Q1.What is your main products?

A1:Our main products are brass forging parts and machined parts.

Q2. How to ensure that every process's quality?

A2:Every process will be checked by our quality inspection department which insures every product's quality. In the production of products,we will personally go to the factory to check the quality of products.

Q3.How long is your delivery time?

A3:Our delivery time is generally 30 to 45 days. Or according to the quantity.

Q4. What is your payment method?

A4:30% value of T/T in advance and other 70% balance on B/L copy.

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges.

Q5.Can you provide a sample?

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees.

Why Us

• Design assistance and full engineering support

• 8 years' experience working with OEM's

• One stop manufacturing includes sourcing of subcomponents and hardware overseas partners

• Complete production lines for custom turning, milling, cnc machining sheet metal fabrication, stamping, bending, sliver welding and surface finish

• Anodize with all kinds of customized colors, zinc and nickel plated, etc.

• Advanced machine tools, CAD/CAM programming software

• Prototype machining capabilities

• Strict quality control standards with a highly qualified inspection department

• Continually upgrading and advancing our equipment to remain competitive

• Extensive capacity - We can run 24 hours, 6 days a week

• If you have any parts to be made, please feel free to send your kind drawings/samples to us

• Our main goal is TOTAL CUSTOMER SATISFACTION while making your job easy!

We Recommend

termonebulizadora smoke machine fog

New Selling 180W High Pressure Fog Machine Fogging Fogger Misting System

10M DIY hot sell Low pressure misting cooling system

New Arrivals

New products from manufacturers at wholesale prices