53L Cheap Price Vaccum Drying Oven

- Category: >>>

- Supplier: Tianjin Lead-Tech Trade Co. Ltd.

Share on (62494145175):

Product Overview

Description

53L Cheap Price Vaccum Drying Oven

Vacuum drying oven

Model | DZF-6020MBE | DZF-6050MBE | BZF-30 | BZF-50 |

Power Supply | ~220V±10V 50/60HZ | |||

Power | 900W | 1400W | 900W | 1300W |

Temp. Range | RT+5~250℃ | |||

Temp. Fluctuation | ±1℃ | ±1℃ | ±0.5℃ | ±0.5℃ |

Vacuum Degree | 133Pa | |||

Volume | 25L | 53L | 25L | 53L |

Working Chamber (mm) | 300×296×275 | 415×370×344 | 300×296×275 | 415×370×344 |

Overall Size (mm) | 590×430×475 | 710×505×550 | 590×430×475 | 710×505×550 |

Shelves | 2pcs | |||

Time Range | 0-999min | 0~99H60min | ||

Model | BX-0.5 | BX-1 | |

Pumping Speed (L/s) | 0.5 | 1 | |

Ultimate Pressure (Pa) | Partial Pressure | ≤6×10-2 | |

Total Pressure | ≤1.33 | ||

Rotary Speed (rpm) | 1400 | ||

Motor Power (kW) | 0.18 | 0.25 | |

Voltage (V) | 220/380 | ||

Inlet Diameter (O.D) (mm) | D20 | ||

Noise Level (dBA) | 65 | ||

Oil Capacity (L) | 0.6 | 0.7 | |

Overall Size (mm) | 447×168×260 | 469×168×260 | |

G.W. / N.W. (Kg) | 17/16 | 18/17 | |

BX-0.5 is suitable for DZF-6020MBE and BZF-30

BX-1 is suitable for DZF-6050MBE and BZF-50

APPLICABLE SCOPE:

The vacuum oven is widely applicable for drying and sterilization in fields of biochemistry, pharmacy, medicine and health, agriculture and scientific research and environment protection. It is designed specially for drying of material which is thermo-sensitive or decompounded and oxidative easily.

ADVANTAGES OF VACUUM DRYING TECHNOLOGY:

Vacuum environment greatly reduced the liquid boiling point which needs to be dislodged, therefore the vacuum drying method is applicable for heat sensitivity material;

For the sample which can't be dried easily, such as powder or other pellet form sample, using vacuum drying method may shorten drying time efficiently;

Various complex structures of machinery ministry or other porous sample process are used of vacuum drying method after washing, and no residues after being dried completely;

Use safer: under vacuum or inertia condition, completely eliminate the possibility that the oxide explosion;

Compare with the normal drying depended on air cycle, powder form sample won't be blowed and moved by airflow.

PRODUCT CHARACTERISTICS(DZF Series):

The shell is made of cold-rolling steel with static spray plastics, the working chamber is made of SUS304 with arc angle design which is convenient to clean the residues;

Temperature control system adopts microcomputer singlechip technology, temperature and time control, over-temperature alarm;

Dual LED screens, the touch keyboard set;

Timing function;

The tightness of door can be adjusted by user optionally, the silicone seal strips whole shaped, ensures the high vacuum degree in working chamber;

The working chamber is rectangular to maximize the volume, the door adopts tempering bulletproof double glass which is easy for observation;

The function of parameters memory and recovery for date protection caused by power failure or system halted.

PRODUCT CHARACTERISTICS(BZF Series):

The shell is made of cold-rolling steel with static spray plastics, the working chamber is made of SUS304 with arc angle design which is convenient to clean the residues;

Temperature control system adopts microcomputer singlechip technology, LCD screen, temperature and time control, over-temperature alarm function;

The tightness of door can be adjusted by user optionally, the silicone seal strips whole shaped, ensures the high vacuum degree in working chamber;

The working chamber is rectangular to maximize the volume, the door adopts tempering bulletproof double glass which is easy for observation;

The function of parameters memory and recovery for date protection caused by power failure or system halted.

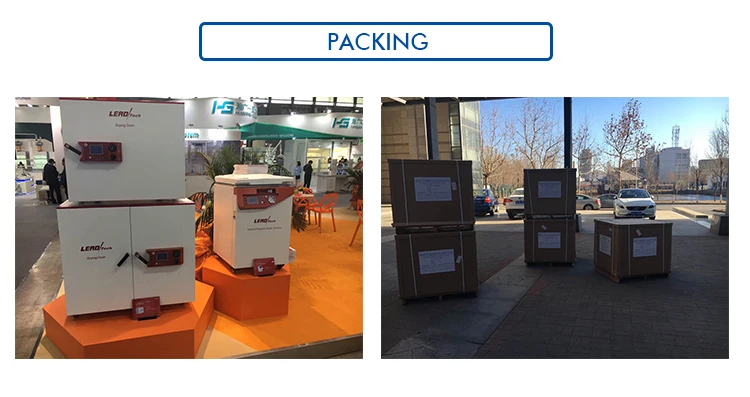

Q: How to transport the product?

A: We transport the product as your requirement. Depending on the quantity and the machine you order or whether you are urgent or not, we will suggest you suitable transportation way. Usually we use sea freight.

Q: What kind of warranty will be offer?

A: For RT PCR and thermal cyclers, the warranty is 24 months from the delivery date. And others are 12 months from the delivery date. During the warranty time, if any problem, we offer after-sale service. For detailed warranty information, welcome to talk this with our sales directly, they will offer you more details;

Q: How about your goods quality?

A: 1. All products comply with CE/ISOstandard.

2. Independent quality inspection team, 100% testing before delivery.

Q: Could you do OEM service?

A: Yes, some types of OEM service available.

Q: How long is your delivery time?

A: We have safety stock for around 80% of running products. 7-30 working days delivery time for stock goods, 60 days for no stock products.

Q: What is your terms of payment?

A: T/T, Western Union, L/C, Credit Card etc. We prefer on-line order and payment.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices