10 / 8 S G Gravel Pumps for Dredger / pompe de dragage

- Category: >>>

- Supplier: Shijiazhuang Naipu Pump Co. Ltd.

Share on (62544590534):

Product Overview

Description

10 / 8 S - G Gravel Pumps for Dredger / pompe de dragage

NP-G sand pump advantages

G pump is designed specifically with advantages of little volume & weight, good wear-resistant & dredging performance, perfectly suited for the dredge on the whole construction.

slurry pumps can be used in various of applications, like Minerals processing, Pipeline transport, High velocity hydraulic transport, Coal prep, Cyclone feeds, Aggregate processing, Fine primary mill grinding, Chemical slurry service, Tailings, secondary grinding, Industrial processing, Pulp and paper, Food processing, Cracking operations, Ash handling etc.

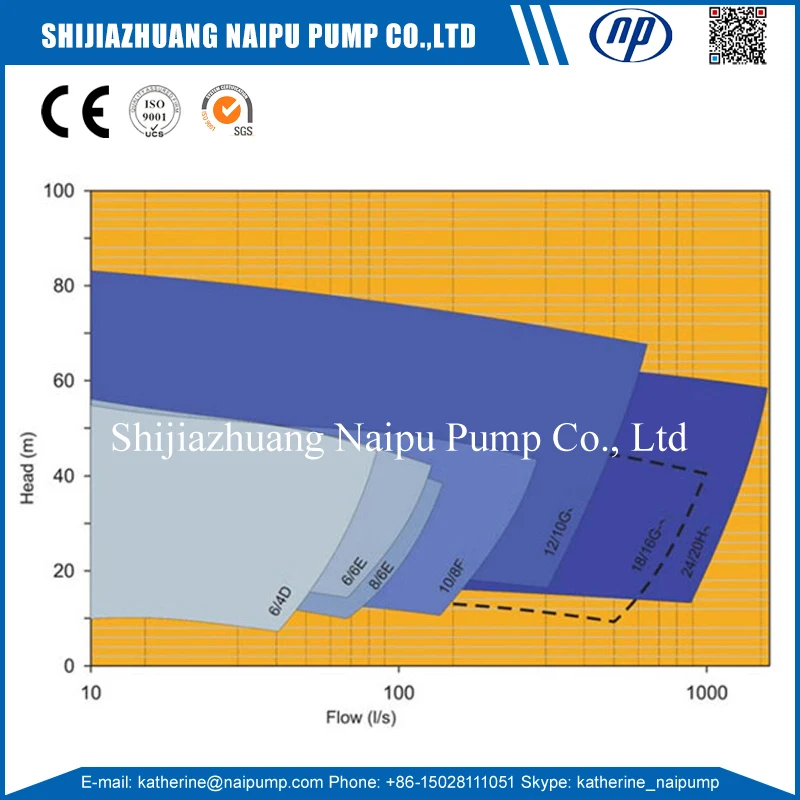

G sand pump selection chart

( Note: Approximate performance for clear water,to be used for primary selection only.)

Sand Gravel pump performance parameters

Model | Flow (m3/h) | Head (m) | Speed (r/min) | Efficiency (%) | Motor (kw) | Drive type

| |

6/4 D-G | 187-36 | 7-51 | 1400-600 | 30-58 | 52-3 | CV.CR.DC | -Slag Granulation |

8/6 E-G | 576-133 | 10-48 | 1400-800 | 60-54 | 88-11 | CV.CR.DC | -Suction Hopper Dredging |

10/8 S-G | 930-216 | 11-44 | 940-500 | 65-34 | 147-22 | CR.DC | -Sand Reclamation |

12/10 G-G | 1512-360 | 11-58 | 850-400 | 70-50 | 305-24 | CR.DC | -Barge Loading |

14/12 G-G | 3168-522 | 9.5-66 | 700-300 | 68-60 | 643-29 | CR.DC | -Sand Reclamation |

16/14 TU-G | 3024-900 | 14-45 | 500-300 | 70-50 | 459-78 | CR.DC | -Sugar Beet |

8/6 F-GH | 648-126 | 15-77 | 1050-500 | 71-50 | 177-12 | CR.DC | -Dredging |

10/8 F-GH | 1091-324 | 19.2-56.5 | 800-500 | 72-60 | 205-32.4 | CR.DC | -Constructional Material |

12/10 G-GH | 2232-612 | 28-77 | 700-450 | 73-60 | 558-89 | CR.DC | -Sand gravel processing |

16/14 TU-GH | 3450-1000 | 72-25 | 500-300 | 78-65 | 2-8 | CR.DC | |

18/16 TU-G | 3600-1050 | 42-12 | 250-450 | 60-72 | 2-8 | CR.DC | |

18/16 TU-GH | 4300-1350 | 70-18 | 250-500 | 60-70 | 2.5-8 | CR.DC |

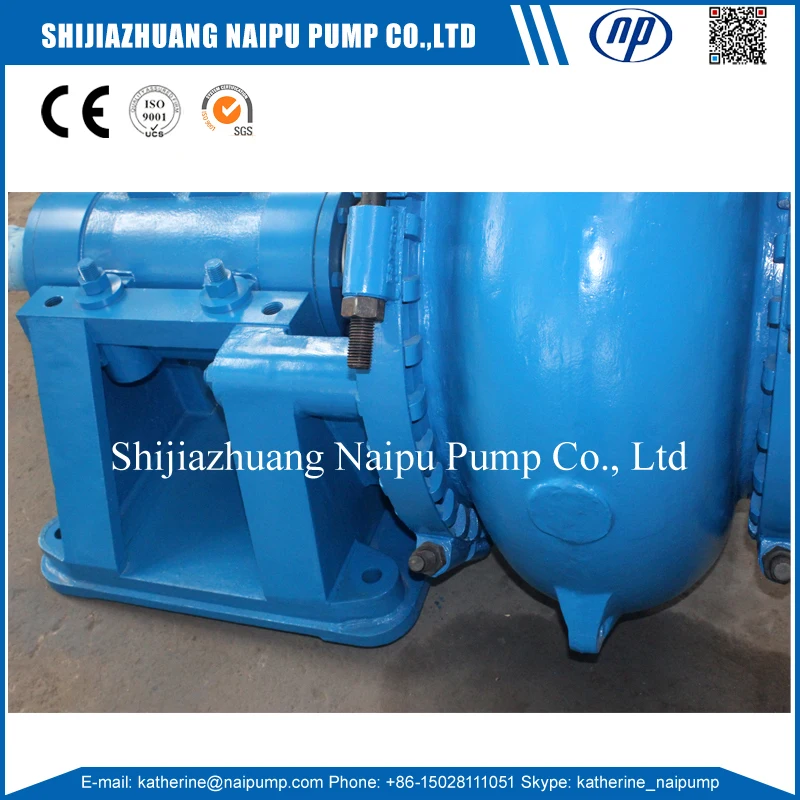

Sand pump construction drawing

Horizontal slurry pump main part number at the drawing

| 003: Base 005: Bearing Assembly 132: Intake Joint Discharge Joint 130: Discharge Flange Intake Flange 013: Cover Plate | 131: Bowl 137: Impeller 041: Back Liner 135: Door Clamp Ring 134: Adapter Plate Clamp Ring 124: Volute Cover Seal |

Mining Pump materials of construction

| VOLUTE | IMPELLERS | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | High Chrome Alloy | High Chrome Alloy | Cast Iron | High Chrome Alloy or SG Iron | High Chrome Alloy or SG Iron | SG Iron | Natural Rubber |

| Options | SG Iron | SG Iron | Mild Steel Fabricated | SG Iron | SG Iron | EN56C Ferralium Hasteloy C Ceramic Stellite Chrome Oxide | Nordel Neoprene Viton Butyl EPDM |

Packaging details: 1. Outside package: standard export wooden cases. 2. Inner package: Stretch film.

What service of Shijiazhuang Naipu?

| OEM service | Produce the pump and spare parts according to client's drawing or sample. |

| Pump slection | Help customers select the type, size and operating speed of pumps that will perform at the lowest cost. |

| Using service | Offer Design, Installation, Repair and Maintenance solutions and Mine measuring up service. |

| Quality control | Pay more attention to the quality in every process with different instruments. |

| Material service | Interchangeable metal design allow best material choice for any application. |

| After-sales service | Provide lifetime after sale service to solve any question during uses and large stock for standard spare parts. |

| Guarantee | One year guarantee for whole machine except of the wet end parts. |

CE, ISO9001, SGS certificate

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps. We have about 30 years experiences and export to worldwide countries. Our technical team consists of talents specialized in hydraulic machinery, casting, heat treatment, engineering, material science and machining. We proudly manufacture quality pumps whose parts are 100% reverse interchangeable with major brands. This means no more inventory hassles when you decide to use another pump supplier.

Katherine Hou

+8615028111051

We Recommend

New Arrivals

New products from manufacturers at wholesale prices