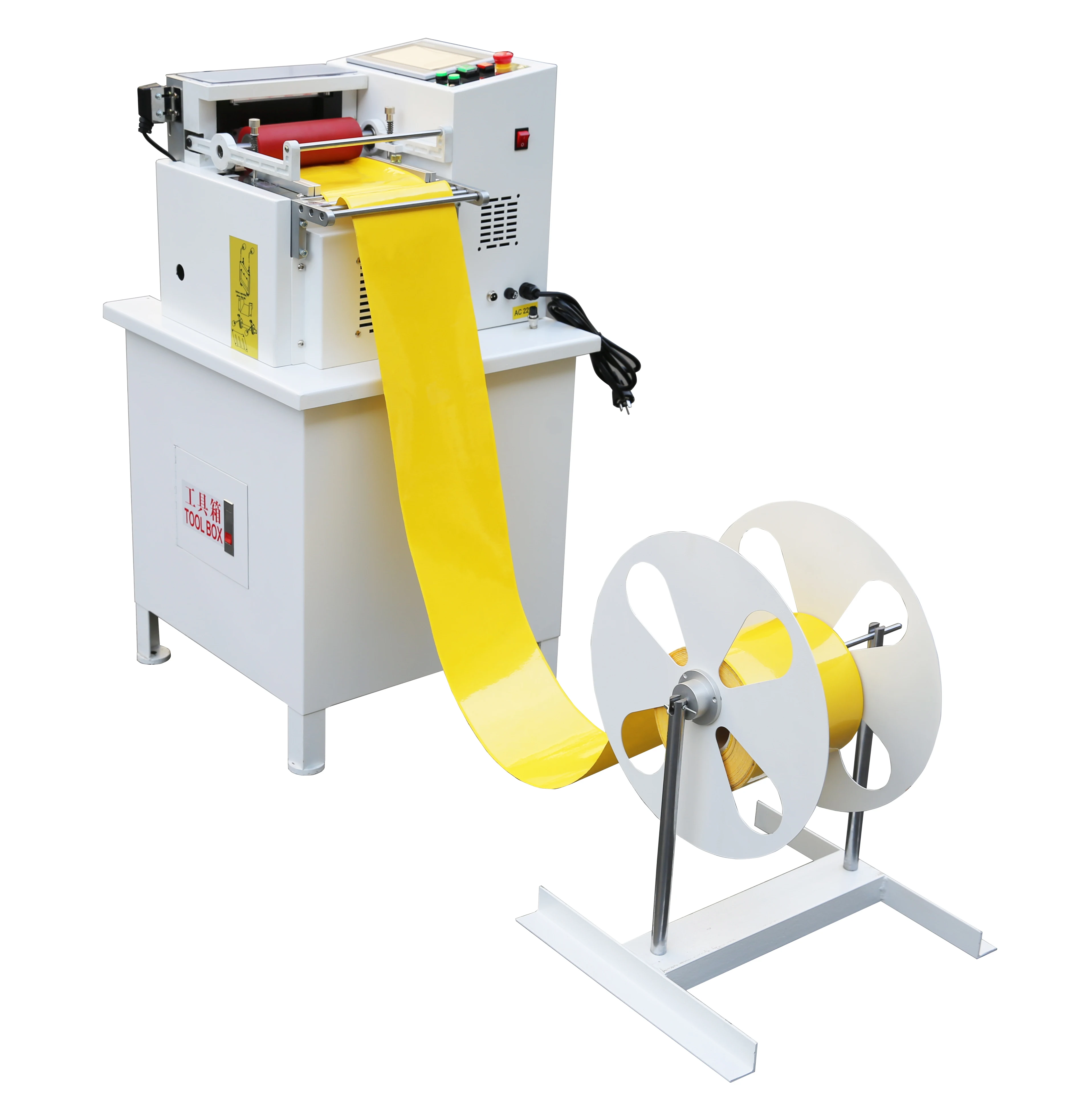

Servo motor controlled automatic sticker cutting machine

- Category: Graph Plotter >>>

- Supplier: Kunshan Yidao Precise Machinery Co. Ltd.

Share on (62579704836):

Product Overview

Description

"with us your MONEY in safe ; your BUSINESS in safe"

YIDAO FACTORY OFFER YOU :

1: FACTORY DIRECT PRICE.

2: NICE QUALITY.

3: NO MOQ ,1PC OK.

4.ONLINE PAYMENT.

5.SUPPORT 7 DAYS REFUND.

WELCOME TO BE ONE OF OUR TOP "VIP" CUSTOMERS". WE BELIEVE THAT " THE QUALITY IS THE SOUL OF AN ENTREPRISE".

WELCOME TO CONTACT US.

Technical parameters:

Item Number | YD-160Q |

Web Width | 0-160mm |

Cutting length | 0-9999.99mm |

Cutting speed | 0-100 cut/min |

Cutting precision | ±0.05mm |

Voltage | 220V |

Size | 550x550x1000mm |

Weight | 133kg |

Total Power | 1.5kw |

*the voltage can customize according to your country standards.

Application:

Sizing cutting for paper,label,sticker,plastic bag,heat shrinking tube, flat cable, PVC sleeve, insulation paper, two-sided tape, Velcro, cotton yarn belt, zipper, etc...

Features:

This cutting machine employs microcomputer controller to set belt cutting length. This machine is ergonomically designed. Operation is easy.

Main functions of belt cutting machine:

Feed material and return material by pressing the button on touch screen

Preset total cutting quantity

Preset cutting length

Preset cutting speed

Preset cut quantity each time ( applied for hot cutting)

Flash cutting quantity finished

Return to ZERO

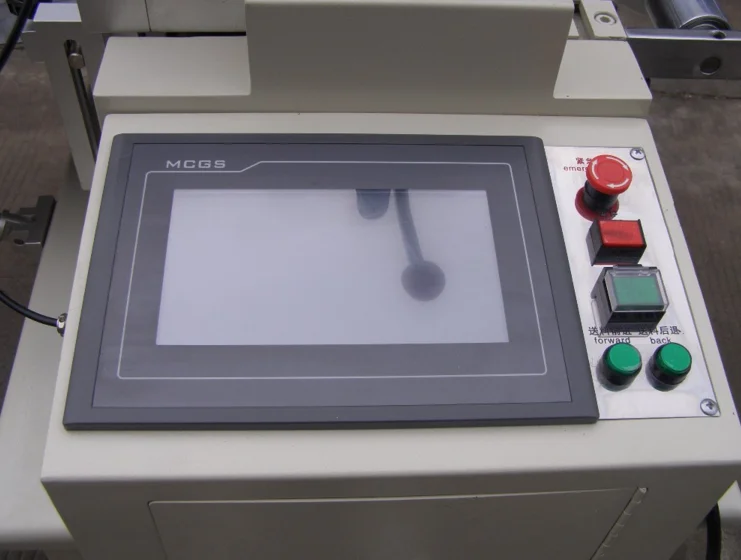

Touch Screen

You can set all parameter in touch screen,such as the length,batch quantity,total quantity,cutting speed,etc.

It's convenient for workers to operate the machine.

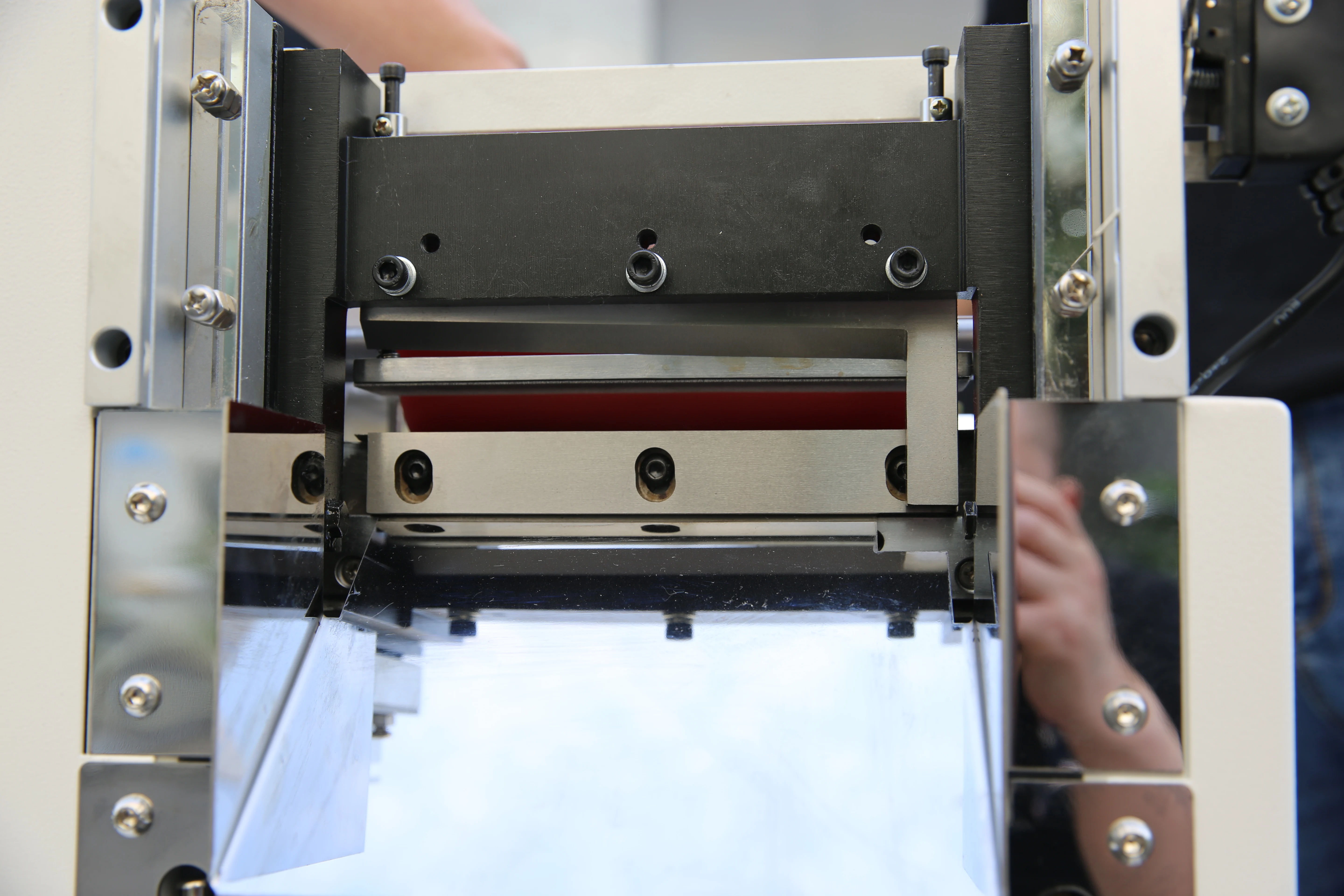

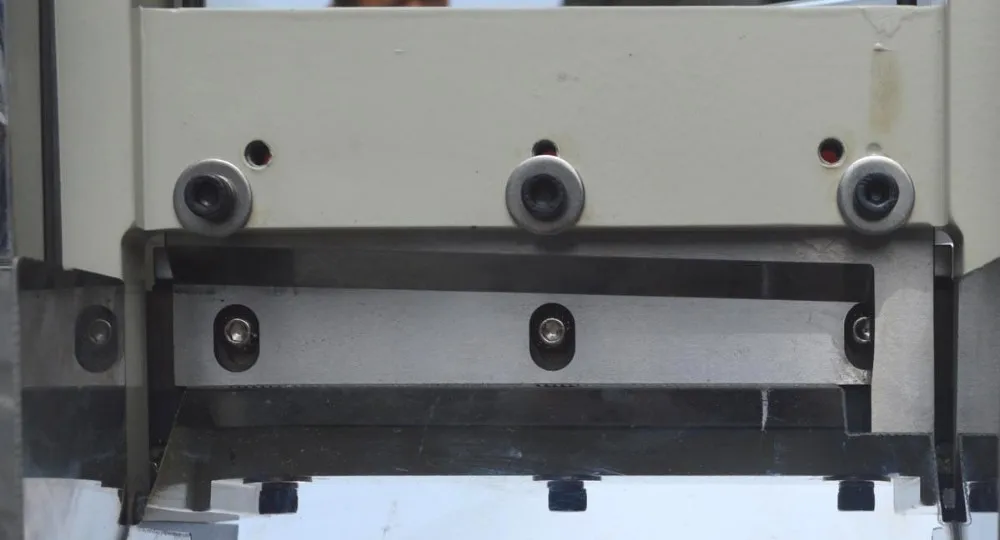

Cutting Blade

Material:SKH-51

Original:Japan

Lifetime:About 20 million times cuts.

Scissor-type cutting blade,durable with highest hardness 65HRC.Easy to adjust,sharp,maintain and change.

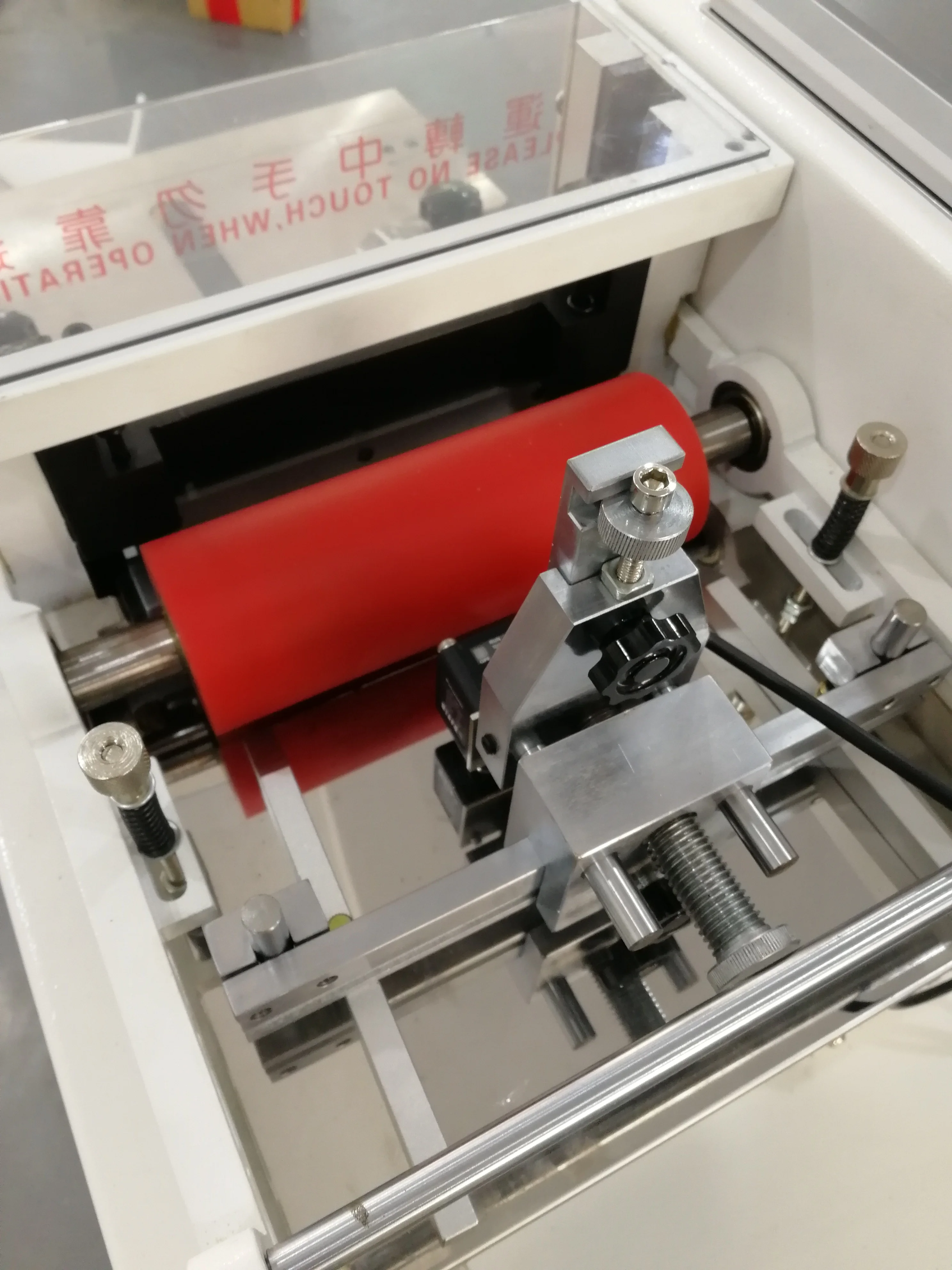

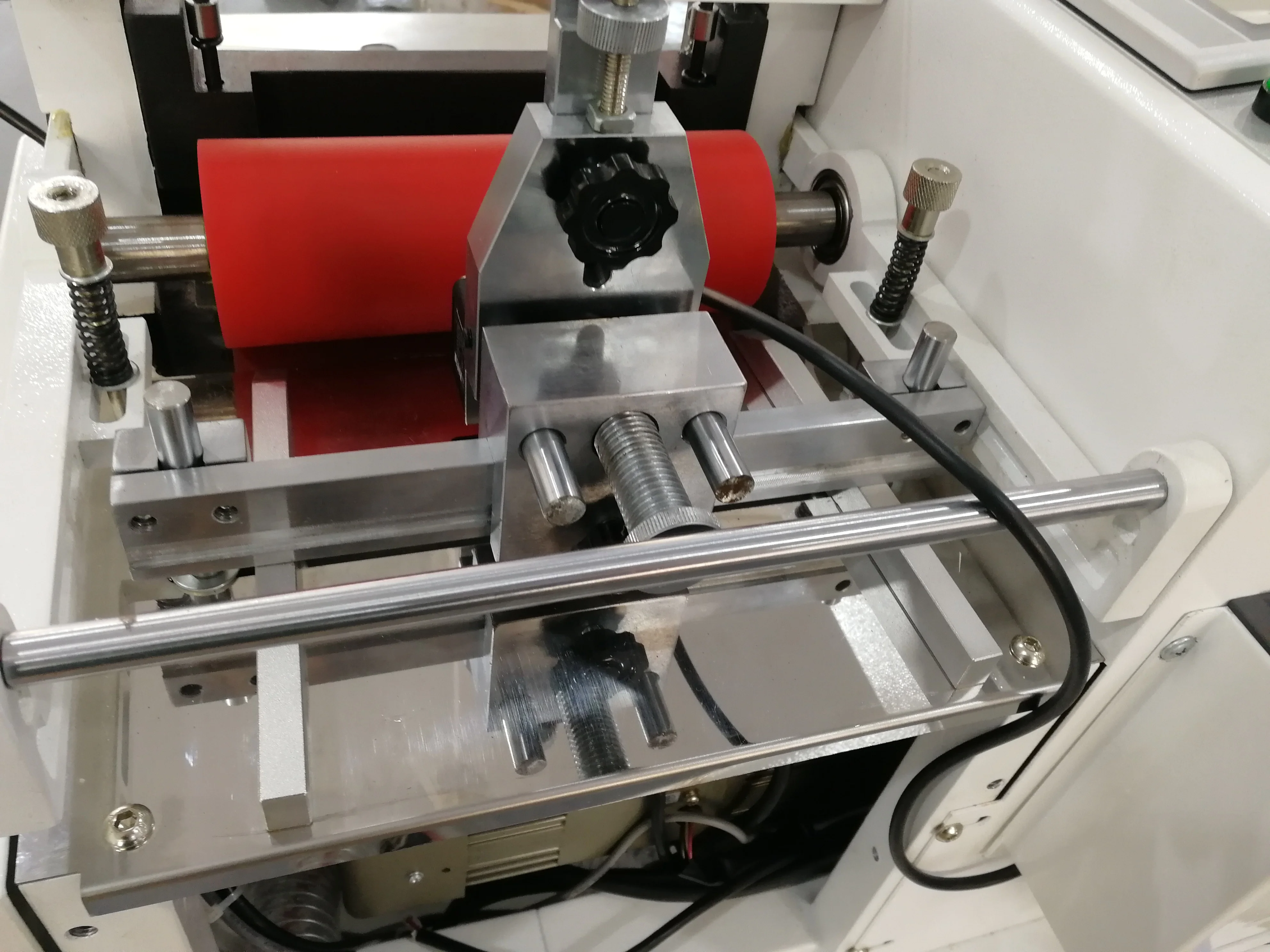

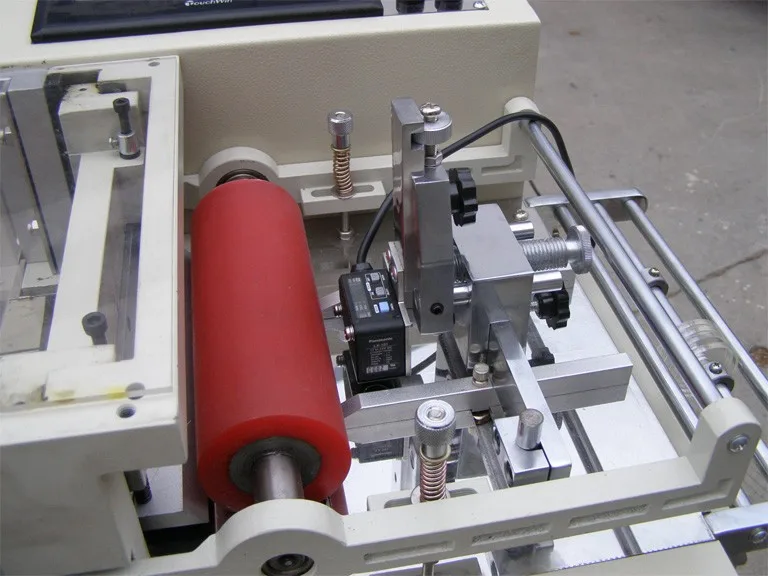

Rubber Feeding Roller

The rubber roll is connected with servo motor,which could feed material with high precision,reach ± 0.1mm.

Simple Material Unwinder

Material unwinder for automatic paper roll to sheet cutting machine.

it supports a simple material roll with light weight.better less than 10KG.

if your material is heavy,other kind of unwinder is optional.

Photo Sensor

If added photo sensor for cutting machine,it can cut thr printed material.the photo sensor will sense the printed marking and make sure the cutting blade cut the material at a specified place.

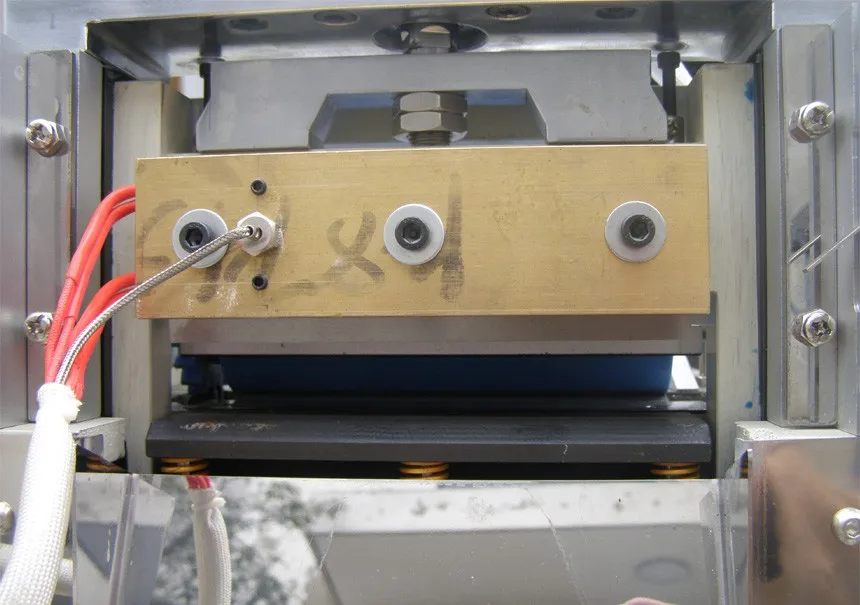

Copper Heater(Hot Cutting)

Adding the hot cutting unit with the blade,copper heater,temperature controller,it can cut and seal the material without burr.

Specially suitable for webbing and non-woven material.

The max temperature can reach 680 degree.

This unwinding device is controlled by motor,you can adjust the speed.

It has sensor to send the material automatically.It could supports about 30KG weight.inflatable air shaft with 3 inch OD.

1.Free sample testing and video for your reference

2. Prompt delivery

3.One year warranty ,whole life technical support

4. Free training in our factory available before delivering machines.

5.24-hours Email technical support, we will do our best to help the clients solve problems.

6. Engineers available to service machinery overseas

7. Technical support: Professional engineers team to help you design a drawing of machine to get highest profit with lowest cost and offer you technical support any time.

8. Other demanded spare part or equipment support: Plenty of cooperated professional supplier for spare parts or other necessary equipment make it possible for us to offer our customers big convenience to complete their production line in high quality with low cost in a short time.

9.Every customer can get one piece of English operation manual , a total working video for machines ,details on every button function ,normal notice when operation .

PACKAGE: we use plywood case for packing the machine to make sure wooden case safe and strong, up to International trade standard. It does not need Fumigation .It's easy for forklift to upload and download .Safety transportation .we will use PE film for packing first before plywood case or pack it according to customers special .

SHIPPING : Usually we suggest customers choose ocean shipping to ship machinery , or air transport for small machine and urgent order . We also supply shipping sevice with our cooperation shipping forwarder to help customers to deliver the machinery in first time .

We Recommend

New Arrivals

New products from manufacturers at wholesale prices