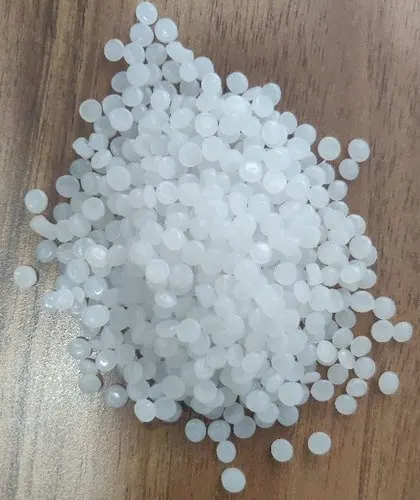

Низкая цена переработанные гранулы hdpe необработанные и HDPE/LDPE/LLDPE/PP

- Категория: >>>

- Поставщик: SM GREEN SUPPLIER CO. LTD.

Сохранить в закладки 10000004877449:

Описание и отзывы

Характеристики

We also have the following products:

- HDPE Clear/Natural Regrind (clean and washed)

- HDPE Clear/Natural Scrap Baled

- HDPE White Regrind/Baled (clean and washed)

- HDPE Milk Bottle Regrind

- LDPE Film Baled 100, 98/2 and 95/2

- LDPE Clear/Natural Regrind

- LDPE White Regrind

HDPE:

HDPE cable material

| Unit

|

|

Mass density

| g/cm 3

| 0.941-0.959

|

Melt flow Rate(190 centidegree /2.16kg)

| g/10min

| ≤1.0

|

Tensile yield strength

| MPa

| ≥19.0

|

Flexural modulus

| Mpa

| ≥965

|

Elongation@ break

| %

| ≥400

|

Impact Embrittlement temperature

| centidegree

| MAX -118

|

Dielectric Constant

| 100KHZ

| 2.32

|

1MHZ

| 2.31

| |

Loss Tangent

| 100KHZ

| MAX 0.0001

|

1MHZ

| MAX 0.0001

| |

Volume resistivity

| OHM-CM

| MIN 1x10 15

|

Application

|

| |

LDPE:

Physical Properties

| Test Method

| Nominal Value

| Unit

| |

Density

| ISO 1183

| 0.921

| g/cm3

| |

Melt Mass-Flow Rate (MFR)

| ISO 1133

| 1.9

| g/10min

| |

Hardness

|

|

|

| |

Shore Hardness (shore D)

| ISO 868

| 45

|

| |

Mechanical Properties

|

|

|

| |

Tensile Modulus

| ISO 527-2

| 175

| MPa

| |

Tensile Strength

| Yield,

| ISO 527-2

| 9.0

| MPa

|

Break,

| 13.0

| MPa

| ||

Tensile Strain(Break)

| ISO 527-2

| 850

| %

| |

Modulus of Elasticity

| Internal Method

| 250

| MPa

| |

Thermal

|

|

|

| |

Vicat Softening Temperature

| ISO 306/A50

| 89.0

| °C

| |

Melting Temperature (DSC)

| DIN 53765

| 108

| °C

| |

Peak Crystallization Temperature (DSC)

| DIN 53765

| 97.0

| °C

| |

Heat of Fusion

| DIN 53765

| 110

| J/g

| |

Electrical

|

|

|

| |

Volume Resistivity

| ASTM D257

| 8.5E+15

| ohm •cm

| |

Dielectric Strength

| ASTM D149

| 30.0

| kV/mm

| |

Dielectric Constant (60Hz)

| ASTM D150

| 2.20

| %

| |

Dissipation Factor (60 Hz)

| ASTM D150

| 0.00050

|

| |

LLDPE

Properties

| Test conditon

| Test method

| Test data

| Unit

|

Density

|

|

| 0.91

| |

MFI

|

|

| 2

| |

Drop impact strength

|

| ASTM D-1709

| 90

| g

|

Elongation ,vertical/horizontal

|

| ASTM D-882

| 600/800

| %

|

tensilestrength,thermal resistance

|

| ASTM D-1004

| 105/95

| Kg/cm

|

elongation

|

| ASTM D-638

| 930

| %

|

tensile strength

|

| ASTM D-638

| 180

| |

tensile strength,vertical/horizontal

|

| ASTM D-882

| 380/350

| |

Vicat softening point

|

| ASTM D-1525

| 103

| °C

|

melting point

|

| ASTM D-2117

| 126

| °C

|

Turbidity

|

| ASTM D-1009

| 12

| %

|

45 glossness

|

| ASTM D-2457

| 75

| %

|

Wholesale Top Grade HDPE Granule / Virgin HDPE Granule Competitive Price

Blowing molding Grade HDPE

Item | Test Condition | Test Method | Value | Unit |

Density |

| ISO 1183 | 0.950~0.955 | g/cm |

MFR | 190°C/2.16kg | ISO 1133 | 1.7~2.5 | g/10min |

Tensile strength at yield |

| ISO 527-2 | 24 | MPa |

Elongation at break |

| ISO 527-2 | >600 | % |

Injection grade HDPE

Item | Test Condition | Test Method | Value | Unit |

MFR | 190°C/2.16kg | ASTM D-1238 | 20 | g/10min |

Density | --- | ASTM D-792 | 0.954 | g/cm3 |

Tensile strength at yiled | --- | ASTM D-638 | 28 | MPa |

Elongation at break | --- | ASTM D-638 | 250 | % |

Impact tensile strength | --- | ASTM D-1822 | 42 | kJ/m2 |

ESCR |

| ASTM D-1693 | 3 | --- |

VACIT | --- | ASTM D-1525 | 127 | °C

|

-=-

Похожие товары

Браслет из бусин и шариков 8 мм из нержавеющей стали, может быть покрыт золотом и розовым золотом, браслет из бусин Будды

HTGK-IV тестер механических динамических характеристик автоматического выключателя

Комплект для электровелосипеда LVCO hub motor 3000w

Модные ювелирные изделия японский и корейский журнал S925 Серебряные иглы простые геометрические одиночные блестящие алмазные циркониевые универсальные температуры

1325/1530 cnc atc маршрутизатор для дверной обработки панель резки сверления cnc atc деревообрабатывающий центр 12 Инструмент линейный журнал

Dollhouse1:12 мини кукольный домик японский журнал Примечания миниатюрная книга

Современный шкаф-книжка из массива дерева шкаф для журналов в японском стиле книжная полка для гостиной Шкафчик высокий шкаф

Новые поступления

Новинки товаров от производителей по оптовым ценам