Порошок сварочного флюса GOLDWELD 115 г высококачественный термитный сварочный экзотермический порошок

- Категория: Welding Fluxes >>>

- Поставщик: MK VIET NAM TRADE AND PRODUCTION COMPANY LIMITED

Сохранить в закладки 10000005940951:

Описание и отзывы

Характеристики

Product Description

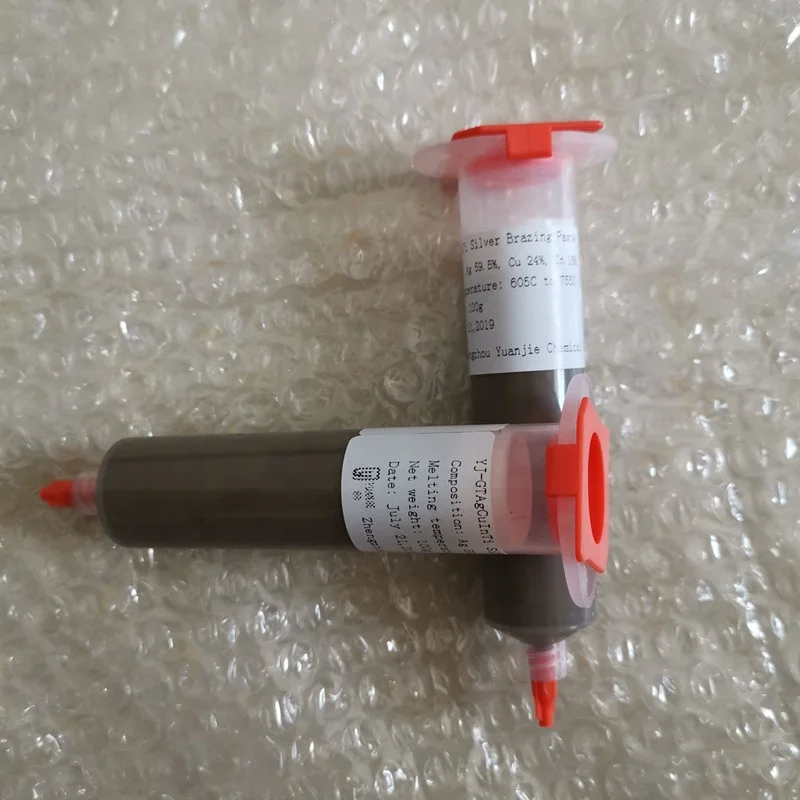

GOLDWELD Exothermic Welding Powder is a powdered weld metal, comprised of copper and aluminium. Exothermic weld is a effortless, profitable and durable welding connection that adopt a high-temperature exothermic reaction to invent a molecular bond. The reaction reaches temperatures over 1500°C thus achieving the fusion of the materials to be welded. Material can be permanently joined within seconds. The conductors are joined by the resulting product of the main reaction when it gets to the solid state. Exothermic Welding does not corrode oxide or degrade with time and is resistant to galvanic coupling. Exothermic Welding offers a permanent welding and a low resistance connection, essential for achieving longwearing and trustworthy results in earthings. Exothermic Welding has an excellent corrosion resistance. GW90, GW115, GW159, GW200, GW250

Specifications | ||

Material | Comprising of copper and aluminium | |

Usage | Exothermic Welding, Industrial Welding, High Speed Welding | |

Color | Grey Black | |

Packing | Plastic Bottle | |

10 tubes/ box | ||

Form | Dry Powder | |

Feature | Fine particle size | |

High activity | ||

Excellent conductivity | ||

Operating Procedures

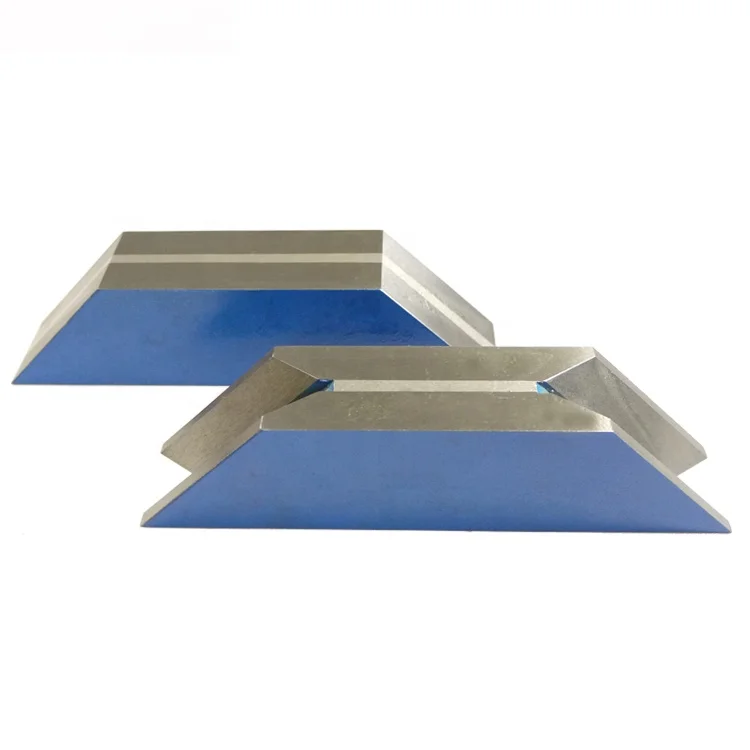

1.\tBefore start the mould welding, should select the appropriate welding mould according to the material specifications and connection type.

2.\tShould wear protective gloves before welding, to prevent scalds!

3.\tBefore the first time using a mould (or use the mould again after cooling), need drying the mould to make its internal moisture dried.

4.\tBefore welding, need to clean and dry the materials for welding to remove its surface dirt, oxide layer and moisture.

5.\tTo prevent mould damage, the part of welding material that place into the mould cavity must be straight, after using mould to clamp it tightly, no outer stress between the mould and welding material was allowed.

6.\tWhen ignite fire powder, the operator must stand on the side of the mould outlet, while no people or inflammable materials exist within 5 meters in the direction of the mould outlet.

7.\tEach time after welding is completed (or prior to welding) the mould need a thorough clean up, each cavity inside of the mould shall be clean well, to sure the quality of welding will not affected by slag accumulation.

1. Placed metal disk in isolation pads, sealed diversion groove.

2. Put the solder powder into mould.

3. For the material that need to be welded, put it into the mold,

clamp the mould tightly.

clamp the mould tightly.

4. Use a point gun to fire ignited powder, while the operator should stand beside the side of mould outlet.

5. 20 seconds later, opening

the mould, cleaning the weld surface

and remove any residue.

the mould, cleaning the weld surface

and remove any residue.

6. Completed conductors

Product packaging

Company Profile

Over 10 years of fighting in the market of lightning protection - heat welding products, MK Vietnam is proud to have a team of experienced, highly technical, creative, and professional leaders and employees who are trained in professional training. We always try our best to bring the best products and services to our partners and customers.

With the company's spearhead product line: GOLDWELD thermal welding - a high quality Vietnamese brand, ready to compete with imported products. All specifications have been rigorously tested, very suitable for construction designs in Vietnam, especially taking a great advantage in terms of price.

With the company's spearhead product line: GOLDWELD thermal welding - a high quality Vietnamese brand, ready to compete with imported products. All specifications have been rigorously tested, very suitable for construction designs in Vietnam, especially taking a great advantage in terms of price.

Why Choose Us

FAQ

Q: Are you trading company or manufacturer ?

A: We are a direct factory with more than 10 years of operation.

Q: How long is your delivery time?

A: It depends on the quantity of goods on your purchase order. Of course we will deliver the goods as soon as possible so that we can keep up with your needs!

Q: Do you provide samples ? Is it free or extra ?

A: Of course! You're welcome!

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% T/T . Payment>=1000USD, 30% T/T in advance, balance before shipment.

A: We are a direct factory with more than 10 years of operation.

Q: How long is your delivery time?

A: It depends on the quantity of goods on your purchase order. Of course we will deliver the goods as soon as possible so that we can keep up with your needs!

Q: Do you provide samples ? Is it free or extra ?

A: Of course! You're welcome!

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% T/T . Payment>=1000USD, 30% T/T in advance, balance before shipment.

We're really proud to cooperate with you! Thank you for your interest in our products!

If you have any questions about our comapny, don't hesitate to contact us immediately. We're ready to support you 24/7.

If you have any questions about our comapny, don't hesitate to contact us immediately. We're ready to support you 24/7.

Contact Us

Mr. Kevin Nguyen

Mobile/WhatsApp: +84335332026

Email: duynguyen@kythuatdienhanoi.com.vn

Mobile/WhatsApp: +84335332026

Email: duynguyen@kythuatdienhanoi.com.vn

Ms. Julia Ha

Mobile/WhatsApp: +84395891223

Email: havan@kythuatdienhanoi.com.vn

Mobile/WhatsApp: +84395891223

Email: havan@kythuatdienhanoi.com.vn

Ms. Ellie Nguyen

Mobile/WhatsApp: +84348255865

Email: amelinda@kythuatdienhanoi.com.vn

Mobile/WhatsApp: +84348255865

Email: amelinda@kythuatdienhanoi.com.vn

Похожие товары

Суперпрочный постоянный треугольный 90 градусов фиксированный Магнитный сварочный держатель

25,20 $ - 33,00 $

Заводская паяльная паста AWS A5.8 BAg-7 из серебра 56% пробы для пайки огнемет медицинское

0,52 $ - 0,58 $

Сварочный флюс SJ101 китайский

Bestool BST-5G 37 г припоя очищайте жало паяльника в виде панды для

2,39 $ - 2,70 $

25/50/75LBS высокое качество стрела Магнитный сварочный

1,70 $ - 4,00 $

Сварочный и паяльный флюс серебристый флюс-4 в пасте с отличной активностью

Sn64.7 bi35ag0.3 низкотемпературный светодиодный чип bst 850 leaded sn63 Тип 4 Тип 6 Профессиональная smt 5g паяльная паста 63 67 для smd

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $