Завод по производству съедобного нефтеперерабатывающего завода

- Категория: >>>

- Поставщик: SHREEJI EXPELLER INDUSTRIES

Сохранить в закладки 10000007069221:

Описание и отзывы

Характеристики

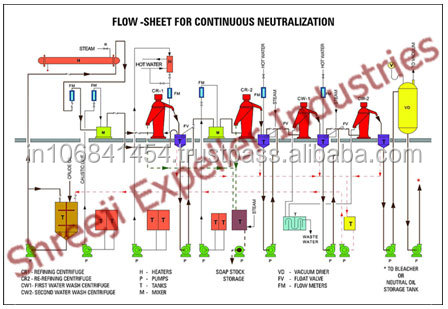

CONTINUOUS VEGETABLE OIL REFINERY PLANT

Basic process of refining is same in both batch & continuous refinery. Only difference is instead of a measured batch, crude oil is processed continuously with constant stream of flow. In between required utilities & chemicals are added continuously in measured quantity. Crude oil from obtained from expellers, solvent extraction plant contains foreign impurities such as mucilage, gums and unfiltered proteinous matter from the seed. It also contains gums which making it unfit for edible

purpose. Basic stages of the process are as below:

- Nutralizing

- Bleaching

- Dewaxing & Deodorizing.

- The crude oil is pumped to Neutraliser from oil mill or storage tank & first it is treated with weak solution of phosphoric

![Continu Type Oil Refinery 2.jpg]() acid or other suitable degumming agent for removing gums.

acid or other suitable degumming agent for removing gums. - Thereafter oil is further treated with measured quantity of alkali (NaoH) depending upon free fatty acid (F.F.A.) in crude oil. In this process soap will be separated.

- Next process is hot water wash to the oil to remove traces of soap particle &

free alkali. - The oil obtained will be light in colour, free from soap stock & called as washed

Neutralised Oil.

- In this process excess colour from the oil is removed. The neutralized washed oil is pumped into the Bleacher vessel

![Continu Type Oil Refinery 3.jpg]() operating under vacuum.

operating under vacuum. - The oil is first heated to remove excess moisture and thereafter it will be treated with predetermined quantity of bleaching earth & activated carbon.

- Thereafter the oil will pass through a filter media (Pressure leaf / Filter press) to separate spent bleach earth and bleached oil.

- The oil will pass obtained after bleaching process is light in colour & appearance of oil will be clear golden in colour

DEODORIZING SECTION:-

- This process removes odour from the oil to improve the quality and self-life of oil.

![Continu Type Oil Refinery 4.jpg]()

- The bleached oil is charged to deodorizer directly or through heat exchanger and is heated at high temperature and also under high vacuum in deodorizer vessel to obtain odourless clear oil.

- Once the process cycle is complete the oil obtained will be odourless & light in colour.

- After cooling it will pass through polishing filter to obtained sparkling light colour & odourless oil for packing, which will be used as edible oil

A very simple requirement of this process is to produce Clear, Brilliant refined oil and to meet certain specifications of Cloud Point.

Sunflower and Rice Bran oil normally contain waxes compared to other oil. Therefore these oils are subjected to de-waxing process called Winterisation Plant, to remove waxes from oil and to produce sparkling good quality edible oils.

To remove the wax, the oil is first processed in Crystaliser where it is cooled by Chilled water circulation. Where the wax is converted into crystal form and there after this will be pass through the filteration process. Now, the wax is separated and the de-waxed oil is collected

SHREEJI know-how gives you an arrangement; you have been looking for since long. Our Crystalliser is Geometrically Designed for Uniform Cooling and effective Nuclei growth of particle.

HYDROGENATION:-

Hydrogenation which is also called Fat Modification is unique 3 phase process system: Solid (Nickel Catalyst), Liquid (Oil) and Gas (Hydrogen). Further a selective reaction, by bringing gas—hydrogen, liquid—oil to the solid—Ni Catalyst and this technological concept formalised an Engineering Design. SHREEJI offers Hydrogenation / Fat Modification Plant, which has several benefits

An oil Expeller allows you the ability to use a wide range of seeds therefore you can produce different types of oils on your plant.

Shreeji Expeller Industries has been established in 1992 by Sh. Naresh Kumar Goyal. It is an internationally reputed manufacturer and exporter of all type of oil extraction machinery and components necessary for oil extraction plants, oil mills, oil refinery plants and bio-diesel plant production houses. The company delivers the top level solutions to clients for every aspect of machinery including designing and erection to commissioning and maintenance.

The firm is an ISO 9001-2008 certified company, delivering full range of services to oil seed processing, oil extraction and related product industries. The company is also affiliated with Engineering Export Promotion Council of India and other prestigious business organization.

Our Head Office is based in Ludhiana. The production unit carries trained technicians, quality control officer, determined working staff and the modern machinery. We have the advantage of being able to develop different models of Oil Expeller / Oil Screw Press, Filter Presses, Seed Cleaners, Boilers, Hammer Mill, Kettles ,refinery etc.

Shreeji Expeller Industries has an excellent in-house production unit equipped with sophisticated machinery and highly competent workforce that enables us to manufacture machinery with utmost precision.

Похожие товары

Полная линия по Переработке соевого масла

Малая установка по Переработке Масла Ши, недорогая машина для переработки масла ши

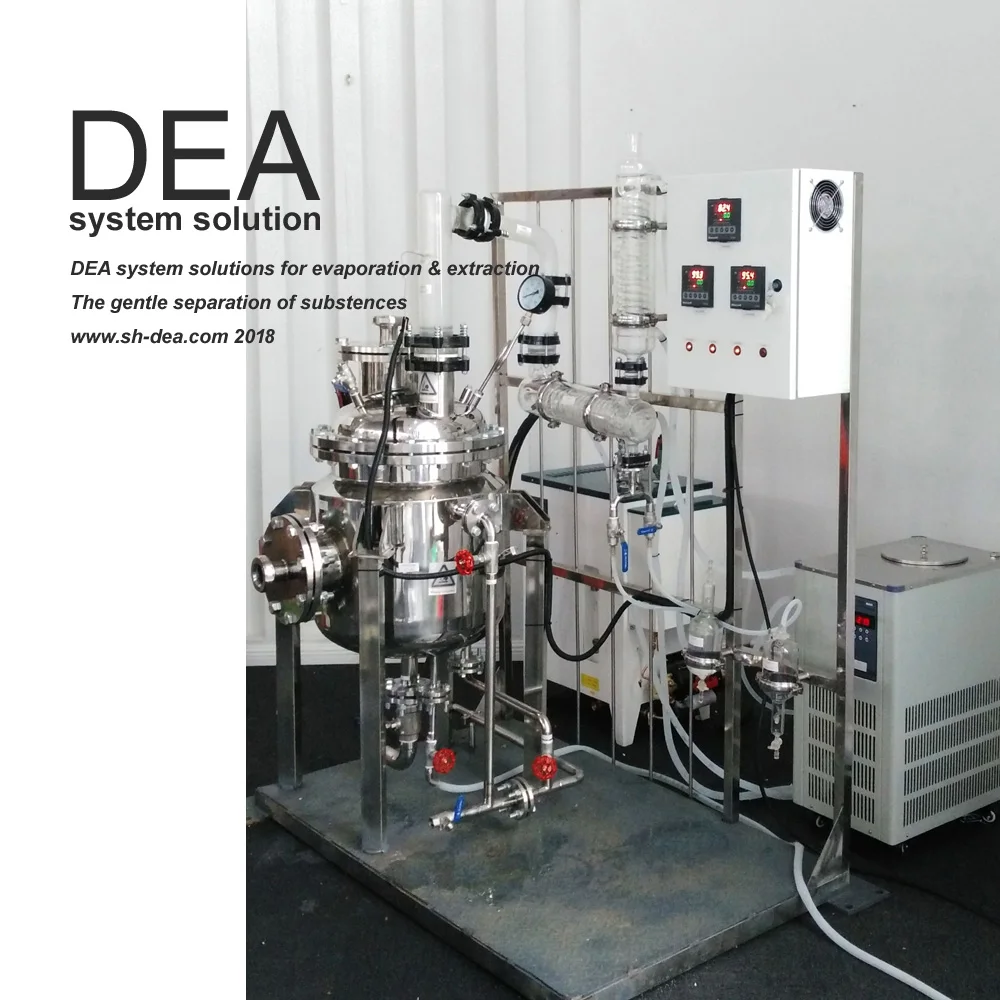

DEA-EX-50 лучшее качество масло семян Ши нефтеперерабатывающая машина рисовых отрубей экстракция масла переработка и подсолнечное масло рафинированное оборудования

Машина для очистки пальмового зерна, установка для нейтрализации и дегумирования масла/дезакисления/обесцвечивания/дезодорирования

Небольшой завод по производству сырого пальмового масла, завод по переработке Красного пальмового масла, производитель Китай

Полная производственная линия, нефтяной Пресс, установка для нефтеперерабатывающего завода

Машина для очистки пальмового масла, установка для очистки сырой пальмового масла, используемая машина для очистки пищевого масла

Новые поступления

Новинки товаров от производителей по оптовым ценам

acid or other suitable degumming agent for removing gums.

acid or other suitable degumming agent for removing gums. operating under vacuum.

operating under vacuum.