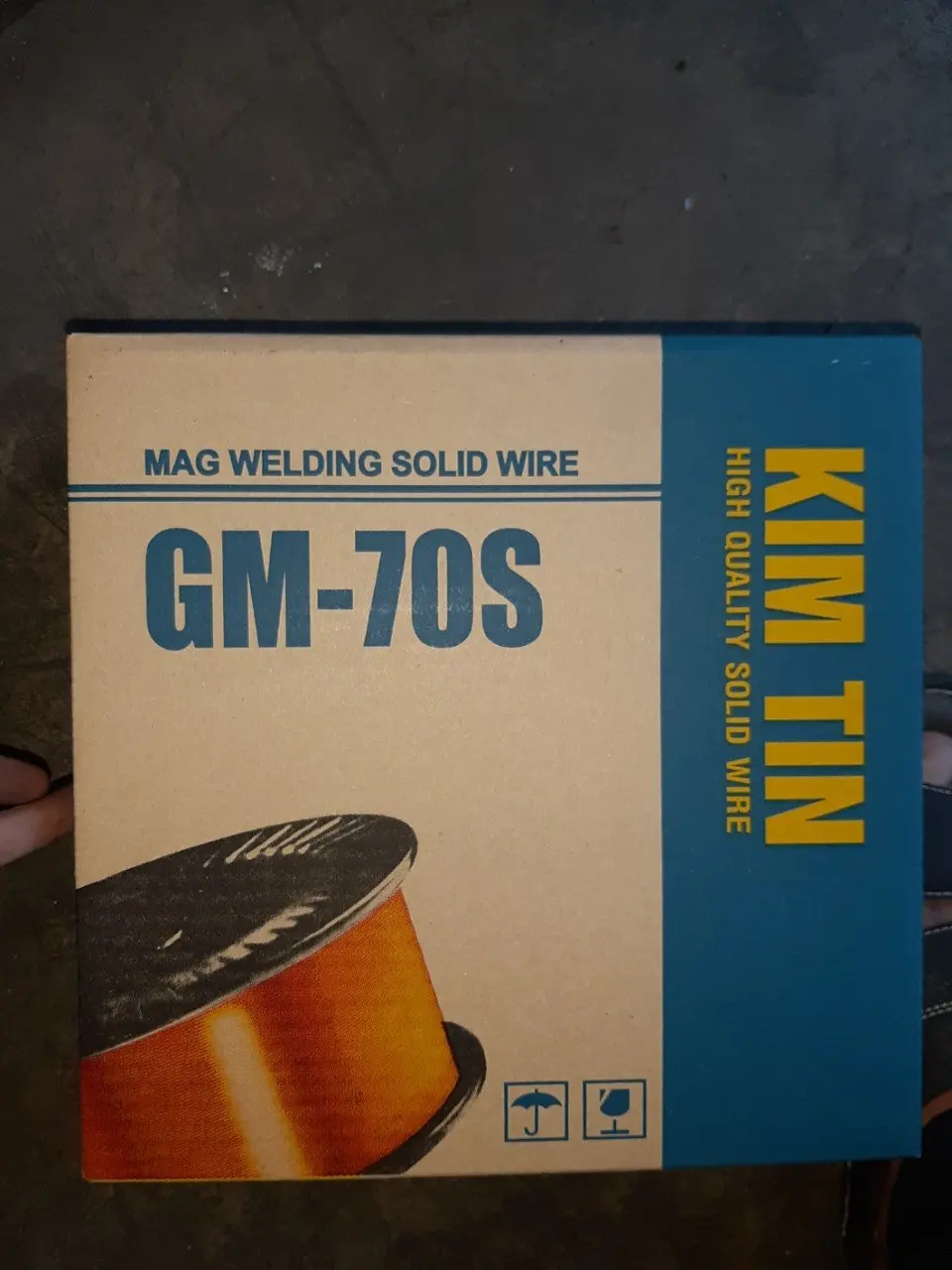

Сварочная проволока AWS A5.18 ER 70S 6 MIG/MAG CO2 медное покрытие твердый сварочный провод для катушек

- Категория: >>>

- Поставщик: KIM TIN GROUP CORPORATION

Сохранить в закладки 10000008649537:

Описание и отзывы

Характеристики

Product Description

Packing details | 15 kg/box 125/250/350 kg/carton | ||

MOQ | 1000kg | ||

Warranty | 1 Year | ||

Payment | T/T, L/C | ||

Specification

item | value |

Warranty | 24 months |

Customized support | OEM, ODM |

Place of Origin | Vietnam |

Ho Chi Minh City | |

Brand Name | Kim Tin |

Model Number | ER70S-6 |

Material | Mild Steel Copper Coated |

Diameter | 0.8mm - 1.6mm |

Melting Point | 100 |

Weight | 5KG/125KG/250KG/300KG/400KG |

Application | engineering machine, vehicle assembling |

Flux Content | no |

Product name | AWS A5.18 ER 70S-6 MIG/MAG copper coated welding wires |

Certification | ABS, CWB, TUV, DB, JIS, CE, ISO9001. |

Feature | Excellent Welding Performance |

Type | CO2 Mig Mag Welding Wire |

Usages | Welding Tool |

Package | Metal Spool or Plastic Reel |

Keyword | Welding Wire Aws Er70s-6 |

Standard | AWS A.5.18 ER70S-6 |

MOQ | 1 Ton |

OEM | Accept |

Product Paramenters

Features and application:

- The advantage of GM - 70S welding wire according to the MIG/MAG welding method is that the welding productivity is 2.5 times higher than that of electric arc welding with protective coating, more diverse and flexible than automatic welding in terms of welding position, during the welding process less toxic gas is generated.

- GM - 70S is a welding wire with low Carbon content, high Manganese and Silicon content, extremely small sulfur and phosphorus impurities, creating welds with high endurance and elasticity.

- GM - 70S is made with high precision, uniform wire direction, plated with a layer of high purity copper

for preservation and stable welding process.

- Gemini GM - 70S Robot welding wire is mainly used in companies that manufacture car components, motorcycles, precision mechanical manufacturing, etc., where welding is done by pre-programmed robot arms.

- GM - 70S is a welding wire with low Carbon content, high Manganese and Silicon content, extremely small sulfur and phosphorus impurities, creating welds with high endurance and elasticity.

- GM - 70S is made with high precision, uniform wire direction, plated with a layer of high purity copper

for preservation and stable welding process.

- Gemini GM - 70S Robot welding wire is mainly used in companies that manufacture car components, motorcycles, precision mechanical manufacturing, etc., where welding is done by pre-programmed robot arms.

Wire chemical compositions (%) | C | Mn | Si | S | P |

0.06 ~ 0.15 | 1.40 ~ 1.85 | 1.40 ~ 1.85 | 0.025 max | 0.025 max |

Deposited Metal Mechanical Properties | Tensile Strength (N/mm2) | Yield Strength (N/mm2) | Elongation (%) | AKV Impact Energy (J) (-30oC) |

480 min | 400 min | 22 min | 27 min |

Diameter of wire (mm) | Ø 0.8 | Ø 0.9 | Ø 1.0 | Ø 1.2 | Ø 1.6 |

Welding current (A) | 80~120 | 90~130 | 100~140 | 110~200 | 180~320 |

Welding voltage (V) | 20~21 | 20~22 | 22~24 | 23~25 | 25~28 |

Gas volume (L)/minute | 8 – 9 | 9 – 10 | 10 – 11 | 12 – 13 | 16 – 18 |

Usage instructions:

1. Fully prepare labor safety factors before welding such as stable welding power source

2. Removes dirt such as oil, rust on the surface of the solder. Bevel to create a full welding gap, conduct welding steps in accordance with regulations.

3. Clean the soldering iron, wire conduit, adjust the wire guides reasonably for the solder wire to be charged stably. Do not let the welding wire get tangled, bent and deformed.

4. When the welding wire is wet, or dirty, the solder is smoked, splashed and unstable, the weld is pitted. Store the welding wire in a dry place, tightly packed to avoid dust, moisture, and avoid contact with the surface of the welding wire.

5. Select the welding current and always maintain the amount of protective gas according to the instructions, maximum wind shielding to be able to get a deep, defect-free, high-workability weld.

5. Select the welding current and always maintain the amount of protective gas according to the instructions, maximum wind shielding to be able to get a deep, defect-free, high-workability weld.

Packing & Delivery

Certifications

Company Profile

Who are we?

Over 22 years of establishment and development, Kim Tin has risen to become a leader in welding materials manufacturing and trading industry. Besides, Kim Tin has also expanded its scale, becoming a corporation dealing in multi-industry such as welding materials, non-ferrous metals, MDF boards, MDF products, mining, transportation...

Kim Tin is constantly researching and producing the best products to serve not only domestic but also overseas customers. We take pride in the fact that Kim Tin welding products have been exported to all 5 continents and we are taking initiatives in building and maintaining strong business relationship with foreign partners.

Why should you choose us?

Kim Tin is constantly researching and producing the best products to serve not only domestic but also overseas customers. We take pride in the fact that Kim Tin welding products have been exported to all 5 continents and we are taking initiatives in building and maintaining strong business relationship with foreign partners.

Why should you choose us?

- Conforming to international quality

- Continuously applying state-of-the-art technology and upgrading factory facilities to meet diverse customer requirements

- Putting credibility first in all business activities

- Moving towards sustainable development, enhancing environmental protection and maintaining consumer health.

- Continuously applying state-of-the-art technology and upgrading factory facilities to meet diverse customer requirements

- Putting credibility first in all business activities

- Moving towards sustainable development, enhancing environmental protection and maintaining consumer health.

FAQ

Q1: Can I have a sample for testing?

A: Yes, we can support sample. The sample will be charged reasonably according to the negotiation between us.

Q2: Can I add my logo on the boxes/cartons?

A: Yes, we have R&D capability and professional & efficient team, OEM and ODM are available from us.

Q3: What are the benefits of being a distributor?

A: Special discounts are available to distributors.

Q4: How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting or installation process, as well as aftersales support.

Q5: Can we mix items in full container?

A: Yes. We ship our products in bulk, usually 40 feet high cube containers, but 20 feet containers are also acceptable.

A: Yes, we can support sample. The sample will be charged reasonably according to the negotiation between us.

Q2: Can I add my logo on the boxes/cartons?

A: Yes, we have R&D capability and professional & efficient team, OEM and ODM are available from us.

Q3: What are the benefits of being a distributor?

A: Special discounts are available to distributors.

Q4: How can you control the quality of products?

A: Yes, we have engineers ready to assist customers with technical support problems, any issues that may arise during the quoting or installation process, as well as aftersales support.

Q5: Can we mix items in full container?

A: Yes. We ship our products in bulk, usually 40 feet high cube containers, but 20 feet containers are also acceptable.

Похожие товары

Конкурентоспособная цена Kc Сертификация 502530 3,7 V 300Mah литий-полимерный аккумулятор

0,70 $ - 0,75 $

Литий-ионная батарея 3,7 В 14500 18650 21700 Lipo Bateria KC Сертификация 18650 аккумуляторная батарея 3,7 В для умных продуктов

Индивидуальные 6000 мАч 8500 перезаряжаемые литиевые железные фосфатные элементы DTP9034128 5000 4000 3000 3 7 В Lipo

1,00 $ - 1,80 $

Новая форма в виде яблока, Классические мини-формы для ручных пирогов, Рождественская выпечка для осени, забавная карманная прижимная лапка для пирога

Сменная литий-ионная батарея 18 в 3000 мАч для пылесоса Dyson V11 с сертификацией KC

Щелочная батарея высокой емкости LR6 AA KC сертифицированная ячейка AM3 1,5 V типа для беспроводной мыши

0,09 $

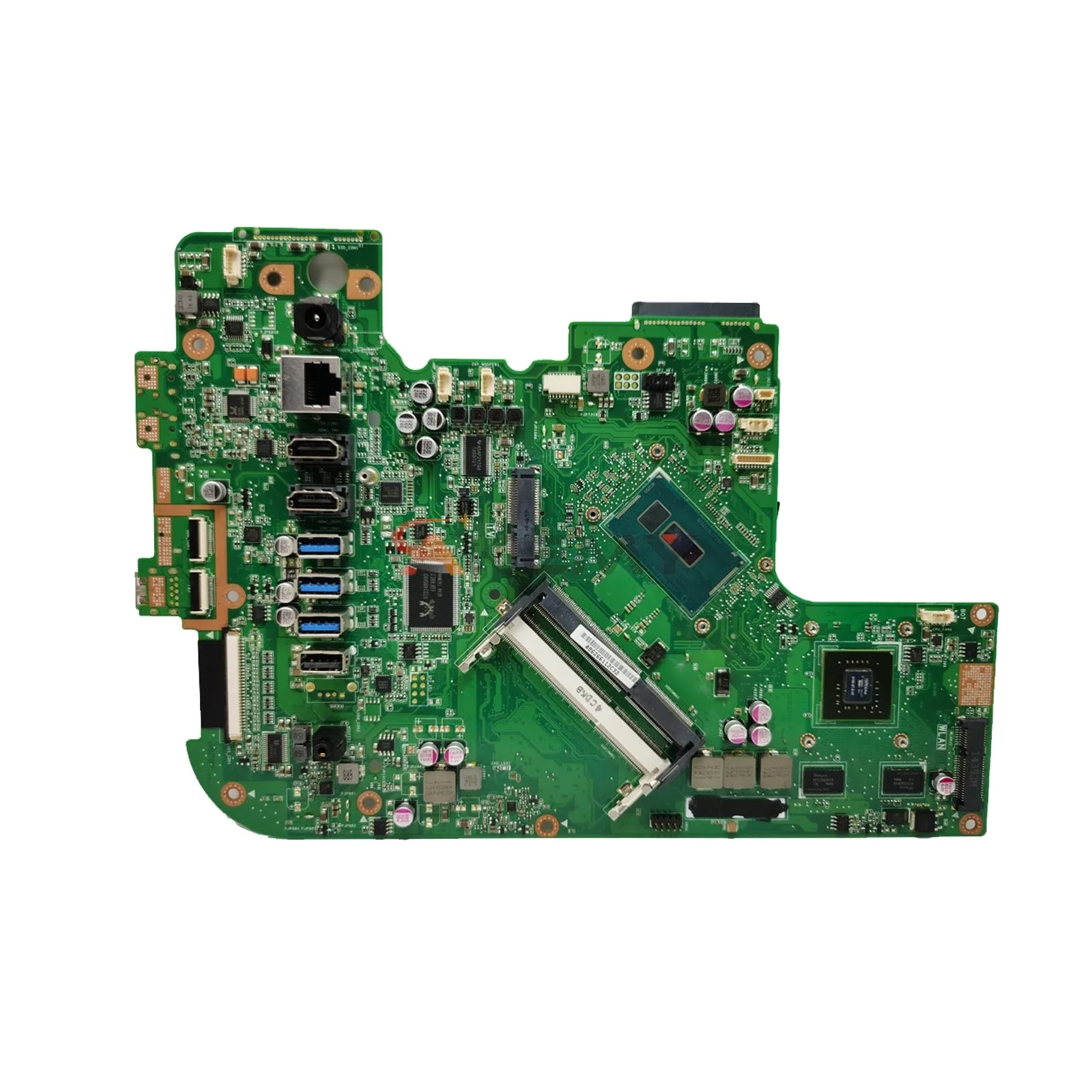

Материнская плата ET2323I для ASUS все-в-одном, ET2323IUT, ET2323, et232323int, материнская плата для компьютера, фотография GT840, тестовая работа 100%

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $