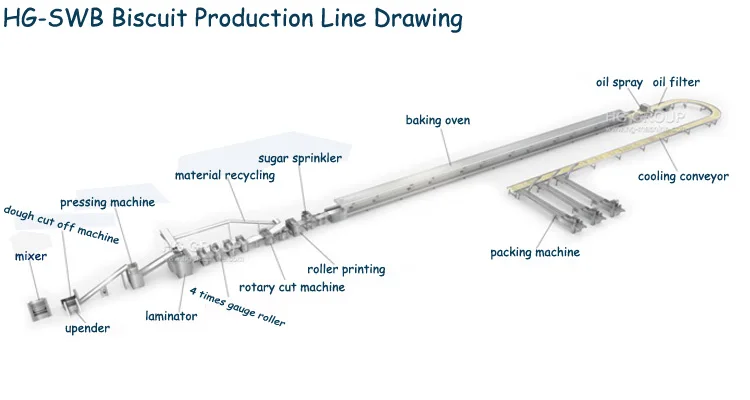

Настраиваемая автоматическая линия по производству печенья для изготовления кукурузных орехов молока с индивидуальной формой и оборудованием

2 741 765,60 ₽

Сохранить в закладки 10000010865666:

Item | Length | Width | Height | Capacity | Type |

HG-SWB280 | 30m | 280mm | 400cm | 100kg/hr | Automatic |

HG-SWB480 | 57m | 480mm | 400cm | 200kg/hr | Automatic |

HG-SWB620 | 70m | 620mm | 400cm | 500kg/hr | Automatic |

HG-SWB1000 | 110m | 1000mm | 400cm | 1000kg/hr | Automatic |

HG-SWB1200 | 135m | 1200mm | 400cm | 1200kg/hr | Automatic |

HG-SWB1500 | 150m | 1500mm | 400cm | 1500kg/hr | Automatic |

Новинки товаров от производителей по оптовым ценам