Оптическое выравнивание Автоматическая Лазерная инфракрасная микросхема устройство для удаления сварного припоя reball SMD BGA переделочная станция мобильного телефона ноутбука

- Категория: >>>

- Поставщик: Shenzhen Dinghua Kechuang Technology Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 10000017500897:

Описание и отзывы

Характеристики

DH BGA rework station for repairing chips of BGA, CCGA, QFN, CSP, LGA, SMD, LED, VGA, etc

DH-A2E automatic BGA rework station Features

2.Automatically

remove,pick up and solder,etc. Which can be exactly instead of a veteran;

3.No damage to devices during desoldering and soldering

(including damage of appearance and function);

4.The desoldering and soldering process does not affect the periphery and back of

the chip;

5.For the preheating temperature, the luminous heating tube is used. The temperature increased is fast and the constant

temperature is stable, and the PCBA desoldered and soldered does not change color or deform;

6.External temperature measurement

interface, convenient to detect the temperature at any time, the tem- perature control is more accurate and reliable; 7.Touch

screen operation, the program is preset in advance, without professional technical training can be skilled in use, so that the

chip disassembled and welded becomes very simple 8.Manual and automatic operation of the two modes, debugging or batch-repair are

more convenient and simple;

9.External usb interface for software updates and import of various repair data into computer analysis

and storage;

10. Disassembling and welding of lead-free or lead products are applicable;

11.Suitable for multiple patch device repair (POP, SOP, SOJ, qfq, QFN, BGA, PLCC, SCP ... );

Specifications | ||||||

1 | Total power | 4900w | ||||

2 | 3 independent heaters | Top hot air 1200w, lower hot air 1200w, bottom infrared preheating 2700w | ||||

3 | Voltage | AC220V±10% 50/60Hz | ||||

4 | Electric parts | 7 inch touch screen + high precision intelligent temp control module + stepper motor driver + PLC + LCD display + high resolution optical CCD system + laser positioning | ||||

5 | Temperature control | K-Sensor closed-loop + PID automatic temp compensation + temp module, temperature accuracy within ±2℃. | ||||

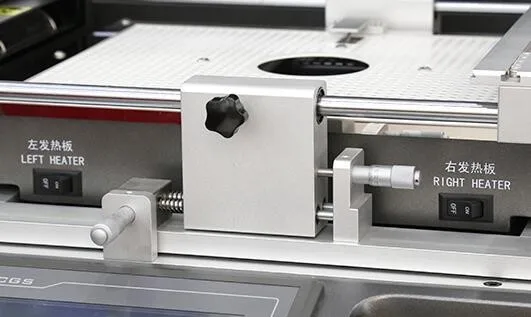

6 | PCB positioning | V-groove + universal fixture + movable PCB shelf | ||||

7 | Applicable PCB size | Max 370x410mm Min 22x22mm | ||||

8 | Applicable BGA size | 1x1mm~80x80mm | ||||

9 | Dimensions | 600x700x890mm (L*W*H) | ||||

10 | Net weight | 70 Kg | ||||

Product Application

Widely used in chip level repairing in following products:

1. Laptop & desktop PCBA

2. Game console, such as Xbox one, Play Station 4 motherboards

3. Mobile phone PCBA, such as iPhone motherboards

4. TV&TV Set-top box motherboard

5. Server, Printer, Camera etc motherboard

Can rework BGA, PGA, POP,BQFP, QFN, SOT- 223, PLCC, TQFP, TDFN, TSOP, PBGA, CPGA, LED chip.

1. Smart PC

1) PLC system, Human-machine interface with 7'' HD Touch screen for easy operation and high accuracy rework.

2) Manage the temperature profile: Setting, Storage, Apply, Analysis, Debug. Up to 8 segments temperature control, 50,000 profile groups storage for different BGA's rework task.

2. Three independent heaters

1) top and bottom heaters are hot-air heating, the third is infrared preheating zone.

2) it can heat PCB board and bga chips at the same time. And the third IR heater can preheat the PCB board from bottom evenly, all three heaters can heat independently .

3) Reliable, Stable and Precise heating process. Temp accuracy is within ±2℃

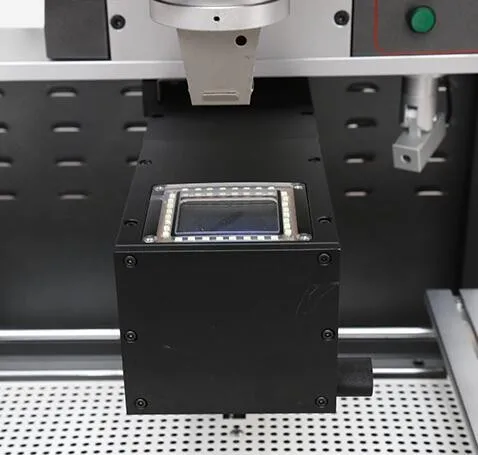

3. Auto Pick-up and mount

1) Built-in Vacuum Pump, integrate the Vacuum Sucker into the Top heater, control by the PC to Pick-up bga chip automatically after desoldering process completed, or mount the bga chip to PCB pad automatically after optical alignment process ok,

2) Mounting head with built-in pressure testing device, to protect the PCB from being damaged.

4. Nozzle

1) All the Nozzles are made with Titanium Alloy.

2) Top Nozzle has Reflow Vent to prevent the damage to surrounding components.

3) Magnetic Nozzle, 360 degree rotation, Easy to install / adjust / change.

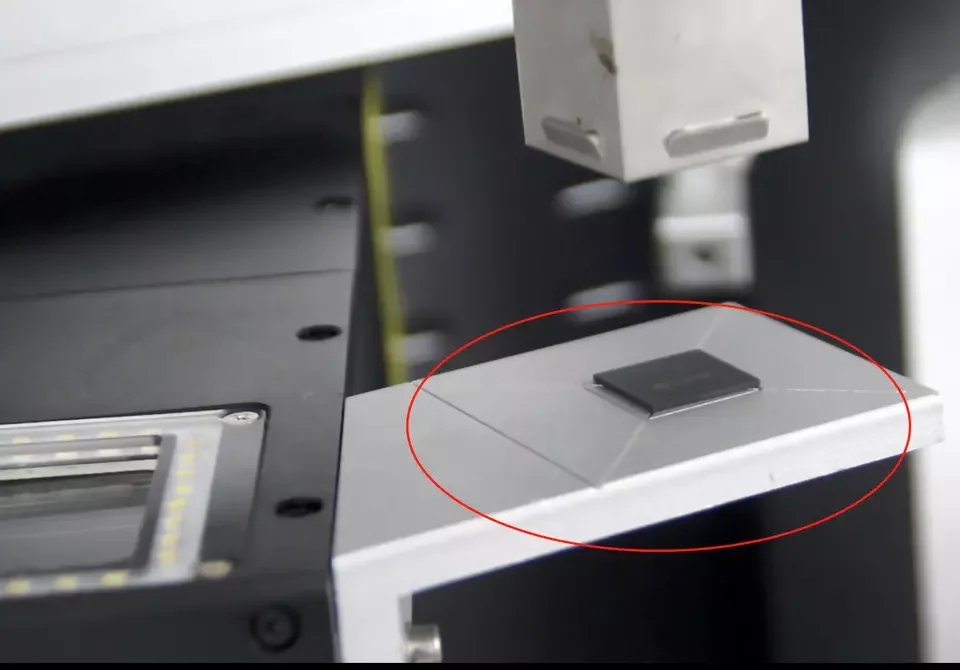

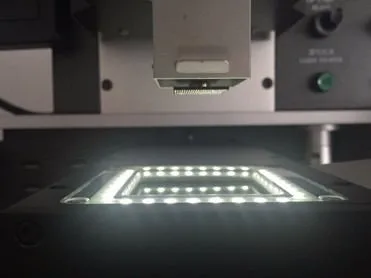

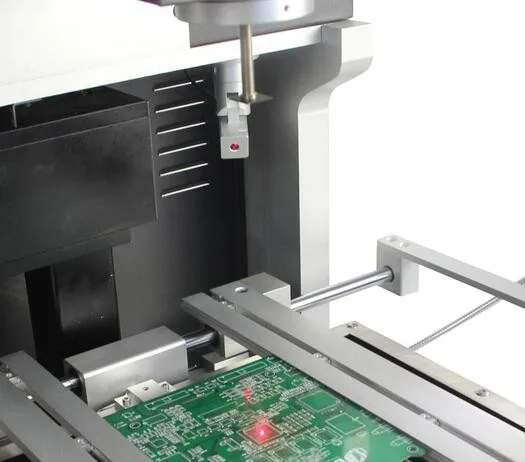

5. Optical alignment system

HD CCD camara Lens, split vision, two color separation

Brand: Panasonic Origin: Japan

1) Highly increase the Accuracy of Chip soldering, Fast Placement, make rework process easier

2) Clear image is displayed on HD LCD monitor

6. Manual & Automatic Modes as your wish

1) Manual: Use Joystick to control the Top Heater(hot air) movement with the assist of Laser point and Optical alignment.

2) Automatic: automatic desoldering and soldering

7. Laser Positioning

Laser assist positioning, fast positioning for doing repeating work on the same type PCB boards, saves you a lot of precious time.

8. Equipped with top air flow adjust button

Prevent the tiny bga chip from moving when upper hot air is blowing

9. Equipped with micrometer

rework BGA chip mounting accuracy is 0.01mm

10. LED Light

A high Power LED light with flexible tube will give you a bright rework, remember that darkness is also a deadly enemy for BGA rework.

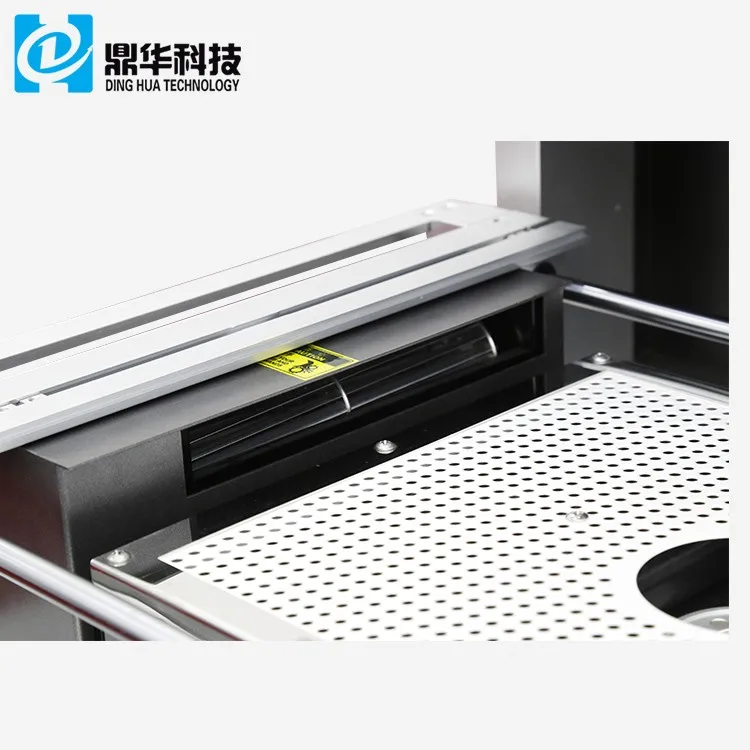

11. Automatic Cooling Fan

1) Cross air flow to cool the PCB after heating, it is important for preventing motherboard from being damaged.

2) fan starts cooling automatically after heating completed, and stops automatically after temperature drops to normal.

3) You can also control the cooling fan manually.

Packaging | ||

Size | 770 (L) * 720(W) * 730(D) mm | |

G.W. | 98.5 Kg | |

Packaging Details | Strong wooden case+ wooden bars+ proof foams | |

Delivery | ||

◆ Sample would be sent within 5 business days after receiving full payment. 7-15 days for bulk order. ◆ Shipping By DHL, FedEx, TNT, EMS, UPS express. You can also choose sea shipment. | ||

1.At pre-sales, free for demonstration and information consults, on site or by video.

2.Can provide process video or training before shipment, at your need.

3. At after-sales, with strong professional technical back-up team.

4. Offer huge discount for messive order volume or for repeated orders.

5.Warranty: 1 year for free, and to receive parts cost for the further years.

1. We are the Manufacturer = own factory+ machine design+Sheet metal produced by ourselves +spray the powder+ strong assemble the machine team + packaging+free training;

2. Logo/Brand: Customer's designs and logos are welcome,we can silk-print your own logo;

3. HUAWEI, SAMSUNG, TCL, ZTE, MEIZU, KONKA, LENOVO, FOXCONN vendor;

4. Have good market in Korea, Japan, NorthAfrica,Vietnam,Brazil,Turkey,India,Mexico and South Asia,The Mid-East and European countries;

5. 100% NEW from Dinghua factory;

6. Over 20 R&D engineers, with 10 year experience;

7. Over 100000 Global User;

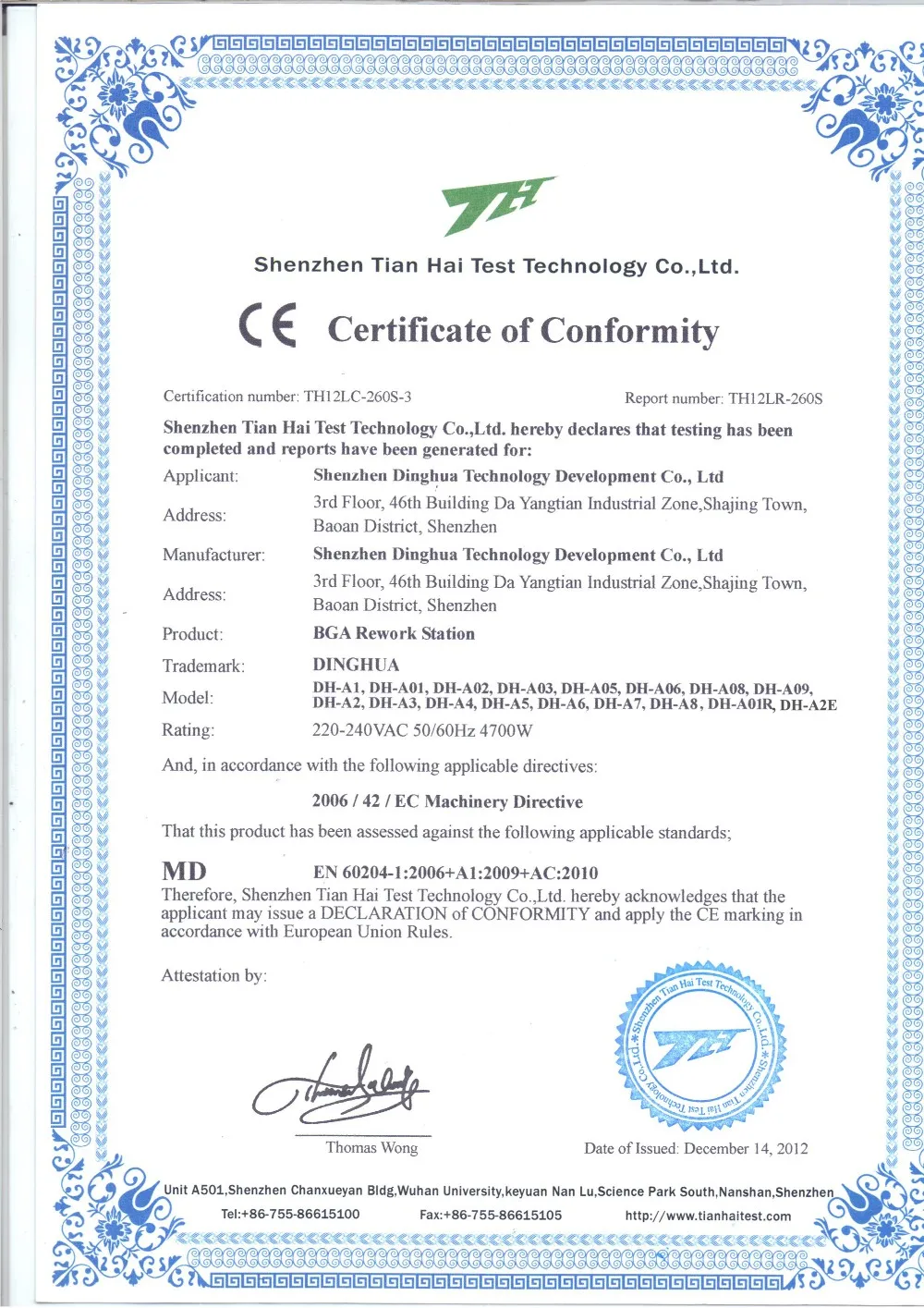

8. All models approved CE ISO9001;

9. 100% QC inspection before shipment;

10. High quality & competitive price.

FAQ

1. How about the package ? Is it safe during the delivery ?

All BGA machine is packed Safely, by standard strong wooden carton with foam inside.

2. What is the delivery way ? How many days will the machine arrrive us ?

We will ship the machine by DHL,Fedex, UPS,etc (Door to Door Service), around 5 days to arrive.

Or by Air to your airport (Door to Airport Service ), around 3 days to arrive.

Or by Sea to the seaport, Minium CBM requirement : 1 CBM, around 30days to arrive.

3. Do you provide the Warranty ? How about the after sales service ?

1 year warranty free for spare parts, Whole life technical support.

We have professional after sales team, if any question, assistant videos are also provided in after-sale service.

4. This machine is easy to use ? if I have no experience, I can also operate it well ?

Do you provide the user manual and operating videos to support us ?

Yes, our BGA machine is designed to use easily, Normally it will take you 2-3 hours to learn how to operate, if you are a technician, it will be much faster to learn.We will provide the English user manual for free , and the operation video is available.

5. If we come to your factory, you will provide the free training ?

Yes, warmly welcome you to visit our factory, we will arrange the free training for you.

6. What is the payment way?

We accept the payment terms: Bank transfer, WesterUnion, Moneygram, Paypal, etc

Contact: Whatsapp/Skype/Wechat:+0086 15768518826

DH-A2 Product Operational Video : https://youtu.be/4uAd6kfnSaY

Dinghua DH-A2E automatic laser infrared hot air bga rework station for chip level repairing in motherboards of computer/mobile phone

economical optical alignment manual bga rework station for motherboards repairing

popular low cost 3 heating zones laser infrared hot air bga rework station 5860

Похожие товары

3D сварочный стол приспособления и зажимные аксессуары 1 шт. Сварочная платформа нитридированный CE ISO заводской

3D сварочный стол приспособления для зажима

Wds-580 Автоматическая ремонтная машина Bga инфракрасная Smd наладочная станция

Высококачественный нитрированный чугунный сварочный стол с аксессуарами для сварки 3D

Автоматическая машина для размывания и намотки олова быстрая 300 50 Вт с параметрическим хранилищем 300B

Интеллектуальная паяльная станция для горячего воздуха 1400 Вт

YIHUA 959D Интеллектуальный бессвинцовый спиральный пистолет 700 Вт паяльная станция для ремонта мобильных материнских плат

Новые поступления

Новинки товаров от производителей по оптовым ценам