Экологичный чехол для наушников

- Категория: >>>

- Поставщик: Shenzhen Topwell Innovations Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 10000017795598:

Описание и отзывы

Характеристики

FAQ

1. What materials do you use for your electronic product enclosures?

* We primarily use high-quality plastics and metals such as ABS, PC, and aluminum for our electronic product enclosures.

These materials are chosen for their durability and precision molding capabilities.

2. What is the typical lead time for manufacturing electronic product enclosures?

* Our lead time varies depending on the complexity and quantity of the order. Typically, it ranges from 2 to 4 weeks for

standard orders. However, for customized or bulk orders, lead times may be longer. Please contact us for specific lead time estimates.

3. Can you provide custom designs for electronic product enclosures?

* Yes, we offer custom design services to meet the unique requirements of our clients. Our experienced design team can work closely with you to develop tailored solutions that match your specifications and branding.

4. Do you provide samples of electronic product enclosures?

* Yes, we offer samples for evaluation purposes. Please contact our sales team to inquire about sample availability and

pricing. Samples are typically provided at a nominal cost, which can be deducted from your final order upon placement.

5. What quality control measures do you implement during manufacturing?

* We adhere to strict quality control standards throughout the manufacturing process. This includes rigorous inspection of raw materials, precision molding techniques, and thorough testing of finished products to ensure they meet our quality

criteria and industry standards.

6. What is your minimum order quantity (MOQ) for electronic product enclosures?

* Our minimum order quantity varies depending on the size and complexity of the enclosure design. Generally, our MOQ starts at 500 units. However, for certain custom or specialized orders, the MOQ may be higher. Please consult with our sales team for specific MOQ requirements related to your project.PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

* We primarily use high-quality plastics and metals such as ABS, PC, and aluminum for our electronic product enclosures.

These materials are chosen for their durability and precision molding capabilities.

2. What is the typical lead time for manufacturing electronic product enclosures?

* Our lead time varies depending on the complexity and quantity of the order. Typically, it ranges from 2 to 4 weeks for

standard orders. However, for customized or bulk orders, lead times may be longer. Please contact us for specific lead time estimates.

3. Can you provide custom designs for electronic product enclosures?

* Yes, we offer custom design services to meet the unique requirements of our clients. Our experienced design team can work closely with you to develop tailored solutions that match your specifications and branding.

4. Do you provide samples of electronic product enclosures?

* Yes, we offer samples for evaluation purposes. Please contact our sales team to inquire about sample availability and

pricing. Samples are typically provided at a nominal cost, which can be deducted from your final order upon placement.

5. What quality control measures do you implement during manufacturing?

* We adhere to strict quality control standards throughout the manufacturing process. This includes rigorous inspection of raw materials, precision molding techniques, and thorough testing of finished products to ensure they meet our quality

criteria and industry standards.

6. What is your minimum order quantity (MOQ) for electronic product enclosures?

* Our minimum order quantity varies depending on the size and complexity of the enclosure design. Generally, our MOQ starts at 500 units. However, for certain custom or specialized orders, the MOQ may be higher. Please consult with our sales team for specific MOQ requirements related to your project.PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Product Features | Design and Manufacturing Strengths |

Material | High-quality plastics and metals |

Design Styles | Diverse designs including modern, fashionable, classic, etc. |

Production Capacity | Large-scale production, capable of producing millions of units monthly |

Technical Process | Advanced injection molding technology ensures product precision and consistency |

Custom Design | Customized design services available to meet individual customer requirements |

Quality Control | Stringent quality control processes ensure adherence to international standards |

Delivery Time | Timely delivery, ensuring customer orders arrive on schedule |

Customer Support | Comprehensive pre-sales and after-sales support to ensure customer satisfaction |

Design Team | Professional design team dedicated to providing innovative and unique product designs |

Engineering Support | Engineering support provided, including mold design optimization, production process optimization |

Brand Collaboration | Collaboration with renowned brands to deliver exceptional products and services to customers |

Manufacturing Experience | Extensive experience in manufacturing phone cases, deep understanding of industry trends and customer needs |

International Recognition | Products exported worldwide, highly praised by international customers |

Похожие товары

Силиконовая форма для мыла

22,44-33,07 ₽

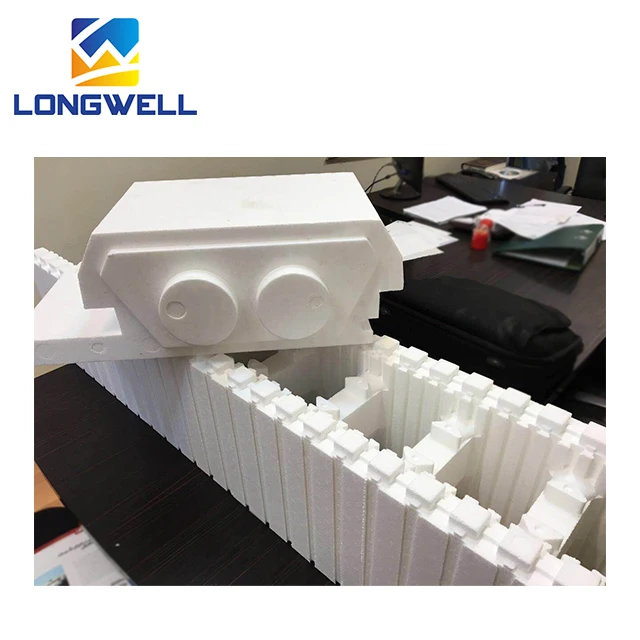

Longwell Горячая продажа EPS пенобетон кирпич плесень с CE

Качественное пластиковое литье под давлением

Пластиковый контейнер для хлеба

1 417 250,40 ₽

Huazhida Высококачественная ПВХ литьевая Форма для обуви

100 388,57-112 198,99 ₽

Многофункциональные формы для монет на заказ от производителя

Пластиковые инъекции два выстрела прессформы впрыски изготовления фабрика инжекционного метода литья резины Overmould двойной цвет

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $