Модульная конструкция 99.5% H2 мембранная установка пленочная система извлечения водорода для газообразного выброса аммиака

- Категория: >>>

- Поставщик: WOBO Industrial Group IncWOBO Inc

Сохранить в закладки 10000019993828:

Описание и отзывы

Характеристики

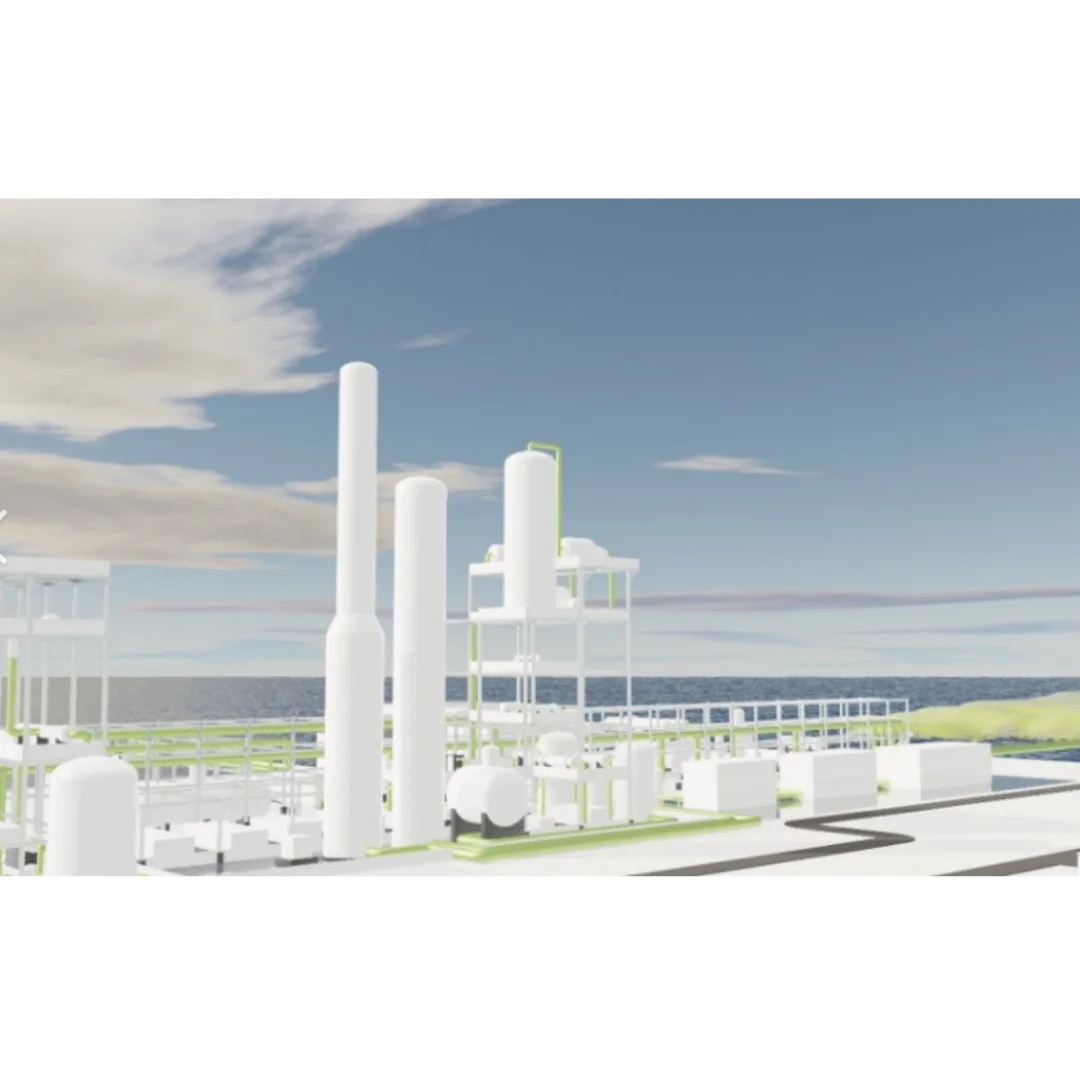

Hydrogen Separation and Recovery Membrane System for Purge Gas from Ammonia Storage Tanks

Small Size Ammonia Purge Gas Hydrogen Separation Membrane Unit Film Hydrogen Treatment Purifier For Ammonia Emission Gas

Product Description

Hydrogen Recovery from Ammonia Purge Gas

Our hydrogen separation and recovery membrane system for purge gas from ammonia storage tanks uses advanced membrane separation technology to efficiently separate hydrogen, improve energy utilization, and reduce production costs.

In ammonia plants, liquid ammonia contains dissolved gases such as H₂, N₂, CH₄, and Ar. When the pressure is reduced, these gases, which were dissolved under high pressure, are released and mix with ammonia vapor, occupying the vapor space of the liquid ammonia storage tank. This gas needs to be vented periodically, with a discharge volume of about 60 Nm³ per ton of ammonia. This is referred to as ammonia tank purge gas or low-pressure purge gas. Its composition (mol%) is as follows:

N2 | NH3 | N2 | CH4 | Ar |

30 | 40 | 8 | 15 | 7 |

Technical Principle

The system uses hollow fiber membrane technology to efficiently separate hydrogen at low pressure. The system is compact in design and easy to operate, and is suitable for various industrial environments. Material selection of high corrosion resistance polymer material to ensure long-term stable operation. The system size can be customized according to customer needs to meet the needs of different production scales.

Feature | Data |

Membrane material | Polymer corrosion resistant material; High permeability, high selectivity |

Separation rate | 99% |

H2 Recovery Purity | 95-99.999 mol%. |

Max. Capacity | Customization |

Product Feature

Features:

• High efficiency separation: Hollow fiber membrane technology, hydrogen separation efficiency up to 99%.

• Energy saving and environmental protection: low energy consumption design, reduce carbon emissions, and meet environmental standards.

• Easy operation: modular design, easy installation and maintenance, simple operation.

• Strong durability: the use of polymer corrosion resistant materials, long service life.

• Customized services: Provide customized solutions according to customer needs, flexibly adapt to different production environments.

• Energy saving and environmental protection: low energy consumption design, reduce carbon emissions, and meet environmental standards.

• Easy operation: modular design, easy installation and maintenance, simple operation.

• Strong durability: the use of polymer corrosion resistant materials, long service life.

• Customized services: Provide customized solutions according to customer needs, flexibly adapt to different production environments.

Application

The high purity hydrogen gas recovered from synthetic ammonia purge gas is widely used in petroleum refining, ammonia gas and methanol production, metal smelting, hydrogen fuel cell, medical treatment, aerospace chemical industry, metallurgical and chemical industry and so on.

Company Profile

Wobo's products cover the fields of new energy, energy, metallurgy, petrochemical, electronics, food, machinery, building materials, medicine, new materials, petrochemical, chemical fiber, heat treatment, glass, national defense and aerospace, and are sold to more than 100 countries and regions.

We strive to provide products with the highest quality and service, and complete with the highest standards. All our products have undergone rigorous testing, and now we have obtained CE,ISO,ASME . Our goal is 100% customer satisfaction,we will provide high-quality productsand value-added services.

Rating & Reviews

Customer evaluation

After using this hydrogen separation system, our production efficiency has been significantly improved, and energy costs have been significantly reduced. ----- Mr. Denis

Customer evaluation

The system is easy to operate, low maintenance costs, after-sales service is also very in place, worth recommending. ----- Mr. Ruben

FAQ

Warranty Policy

* Warranty Period: All products come with 18 months free warranty from the date of purchase.

* Warranty Coverage: During the warranty period, we will repair or replace parts free of charge for defects related to product quality.

* Out-of-Warranty: Repairs after the warranty period will incur a fee. Please contact customer service for details.

Return and Exchange Policy

* Return/Exchange Conditions: If there is a quality issue or if the product does not match the order, please contact customer service within 7 days of receiving the item to request a return or exchange.

* Return/Exchange Process: Call our customer service hotline or send an email to request a return or exchange. We will provide you with the return address and instructions.

Technical Support

* Support Service: We offer 24/7 technical support via phone, email, and online chat.

* Remote Support: Technical assistance is available through phone, email, and online chat.

* On-Site Support: For issues requiring on-site attention, we will arrange for a technician to visit.

Customer Feedback

* We value your feedback. Please share your experience via our customer service hotline or email. Your input helps us improve our service quality.

Training and Support

* New Customer Training: After purchase, we provide detailed training and user guides for the product.

* Extended Warranty: You can choose to purchase an extended warranty for additional coverage.

* Custom Services: We offer personalized customization services based on your needs. Please consult customer service for details.

* Warranty Period: All products come with 18 months free warranty from the date of purchase.

* Warranty Coverage: During the warranty period, we will repair or replace parts free of charge for defects related to product quality.

* Out-of-Warranty: Repairs after the warranty period will incur a fee. Please contact customer service for details.

Return and Exchange Policy

* Return/Exchange Conditions: If there is a quality issue or if the product does not match the order, please contact customer service within 7 days of receiving the item to request a return or exchange.

* Return/Exchange Process: Call our customer service hotline or send an email to request a return or exchange. We will provide you with the return address and instructions.

Technical Support

* Support Service: We offer 24/7 technical support via phone, email, and online chat.

* Remote Support: Technical assistance is available through phone, email, and online chat.

* On-Site Support: For issues requiring on-site attention, we will arrange for a technician to visit.

Customer Feedback

* We value your feedback. Please share your experience via our customer service hotline or email. Your input helps us improve our service quality.

Training and Support

* New Customer Training: After purchase, we provide detailed training and user guides for the product.

* Extended Warranty: You can choose to purchase an extended warranty for additional coverage.

* Custom Services: We offer personalized customization services based on your needs. Please consult customer service for details.

Похожие товары

99.99% H2 Аммиачная пленка для улавливания выхлопных газов очиститель мембранный водородный Газ производства химических удобрений

41 000,00-59 000,00 $

Газовая хроматография GC-FID высокой чистоты N2 газовый лабораторный генератор азота

630,00-660,00 $

Генератор азота для упаковки пищевых продуктов генератор бесконечности

5 000,00-5 500,00 $

Конкурентоспособная цена PSA генератор водорода для промышленности

16 150,00-19 000,00 $

Настенный озоновый газоанализатор

2024 бестселлер установка Ln2 для производства жидкого азота использования в замороженной сперме

Расширенная мембранная установка для улавливания углерода 1 5 т/ч 99% чистоты Ptfe полая мембрана Co2 генератор небольшой продажи

86 250,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $