Сделано в Италии ручной цифровой контроллер с быстрым сканером 90 углов автоматизация SAI трековая температура

- Категория: >>>

- Поставщик: S.A.I. SOCIETA AUTOMAZIONE INDUSTRIALE S.R.L.

Сохранить в закладки 11000000542329:

Описание и отзывы

Характеристики

Product Description

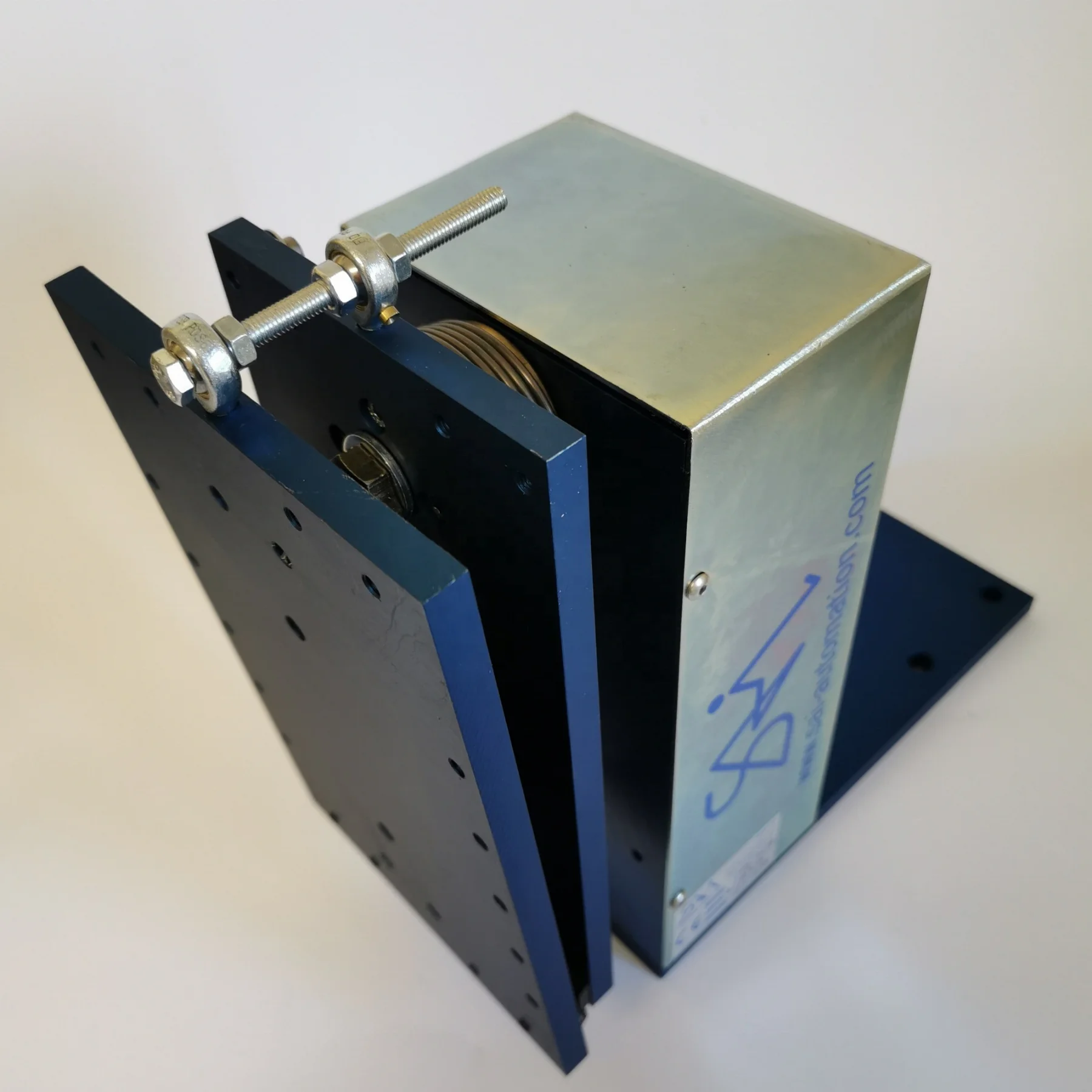

Manual control of scanner positioning

The supply includes a small box (7x7x12cm) suitable for integration into a control desk, equipped with a 110V / 220V power supply.

The potentiometer, with scale set as a percentage (0-100%), allows you to move the scanner along the entire scanning range, whether 30 °, 50 ° or 90 °

The blue led shows the volts corresponding to the position: a self-diagnostic system to verify the correct functioning of the

system.

The potentiometer, with scale set as a percentage (0-100%), allows you to move the scanner along the entire scanning range, whether 30 °, 50 ° or 90 °

The blue led shows the volts corresponding to the position: a self-diagnostic system to verify the correct functioning of the

system.

The FAST version of the automatic positioning scans an area of 90° wide and it lasts 6 seconds.

The wide range of versions available supports a different uses: the scan covers an area of 30 °, 50 ° or 90 ° in 6 or 30

seconds.

For aluminum extrusion applications, the assembly is perpendicular to the press, possibly right on the output plate of the profile exit, at about one meter in height. The sensor, moved by the scanner automatically, reads the entire surface of the profile right next to the press exit and it captures the most accurate data possible.

The scanner can be managed independently by the IES Isothermal Extrusion system, or managed separately automatically or manually with a dedicated kit, purchased separately.

A correct reading of the profile temperature is important for controlling the extrusion process. For dies already in use, when changing the die, the scanner automatically moves the sensor to the position saved during the last extrusion of that specific die, using the parameters saved in the recipes in the IES Isothermal Extrusion system.

With a new die, the scanner positions itself at 45 degrees and evaluates the temperature and emissivity read. If the signal does not fall within the reading parameters accepted by the system, or if for any reason the signal is interrupted, the scanner automatically starts the search for a new position satisfying the necessary requirements (temperature and emissivity). At the end of the extrusion the value of the position is saved, with all the other parameters, in the die recipe and made available for subsequent reuse of the die.

Included in delivery:

1 Scanner

1 Manual Positioning Tool (MPBN)

1 4-pin connectors with 30 meters of cable for MPBN-Scanner connection

1 110V / 220V power supply

Drawings and User Manual

SENSOR NOT INCLUDED

The wide range of versions available supports a different uses: the scan covers an area of 30 °, 50 ° or 90 ° in 6 or 30

seconds.

For aluminum extrusion applications, the assembly is perpendicular to the press, possibly right on the output plate of the profile exit, at about one meter in height. The sensor, moved by the scanner automatically, reads the entire surface of the profile right next to the press exit and it captures the most accurate data possible.

The scanner can be managed independently by the IES Isothermal Extrusion system, or managed separately automatically or manually with a dedicated kit, purchased separately.

A correct reading of the profile temperature is important for controlling the extrusion process. For dies already in use, when changing the die, the scanner automatically moves the sensor to the position saved during the last extrusion of that specific die, using the parameters saved in the recipes in the IES Isothermal Extrusion system.

With a new die, the scanner positions itself at 45 degrees and evaluates the temperature and emissivity read. If the signal does not fall within the reading parameters accepted by the system, or if for any reason the signal is interrupted, the scanner automatically starts the search for a new position satisfying the necessary requirements (temperature and emissivity). At the end of the extrusion the value of the position is saved, with all the other parameters, in the die recipe and made available for subsequent reuse of the die.

Included in delivery:

1 Scanner

1 Manual Positioning Tool (MPBN)

1 4-pin connectors with 30 meters of cable for MPBN-Scanner connection

1 110V / 220V power supply

Drawings and User Manual

SENSOR NOT INCLUDED

Specification

item | value |

Warranty | 2 years |

Customized support | OEM |

Place of Origin | Italy |

Brand Name | S.A.I. SRL |

Model Number | MPBN-06-90 |

Packing & Delivery

Product is wrapped in bubble wrap, placed in a cardboard box and protected from impacts with packaging material

The box has the appropriate size and shape to protect from damage during transportation

Every box is checked before leaving our company

The box has the appropriate size and shape to protect from damage during transportation

Every box is checked before leaving our company

Recommend Products

New fully integrated solution for even more practical use.

The choice of advanced and decidedly performing components integrate in a small die-cast aluminum box all the technology necessary

to detect the sound of metal impacts and send a signal via the connected 5m cable.

The choice of advanced and decidedly performing components integrate in a small die-cast aluminum box all the technology necessary

to detect the sound of metal impacts and send a signal via the connected 5m cable.

Ref. AIO

The management of the liquid nitrogen flow involves the use of a cryogenic valve that can withstand the low temperatures of the

liquid state of nitrogen (-196 °).

Controlling the proportional opening of the valve, the waste of liquid nitrogen is considerably reduced, using

only the quantity necessary for the production in progress.

The excellent results of this system are also evident in the gloss of the surface thanks to the inertization properties of the nitrogen which, in contact with the hot profile, changes from liquid to gaseous, protecting it from oxidation.

Furthermore, even after aging treatments, the hardness of the material benefits from cooling the die with liquid nitrogen.

liquid state of nitrogen (-196 °).

Controlling the proportional opening of the valve, the waste of liquid nitrogen is considerably reduced, using

only the quantity necessary for the production in progress.

The excellent results of this system are also evident in the gloss of the surface thanks to the inertization properties of the nitrogen which, in contact with the hot profile, changes from liquid to gaseous, protecting it from oxidation.

Furthermore, even after aging treatments, the hardness of the material benefits from cooling the die with liquid nitrogen.

Ref APBN_LN_CL

Automatic calculation of the cooling rate.

The supply includes a scanner to be used with sensor for detecting the temperature of the profile immediately at the exit press, a second scanner to be used with sensor with characteristics suitable for detecting the lower temperature after cooling (both with air and water or

even mixed).

The supply includes a scanner to be used with sensor for detecting the temperature of the profile immediately at the exit press, a second scanner to be used with sensor with characteristics suitable for detecting the lower temperature after cooling (both with air and water or

even mixed).

Ref. APBN_QR

Company Profile

With 40 years of expertise to rely upon in automation of aluminium extrusion plants, S.A.I. srl provides highly capable and

reliable controls, programming, software and complete automation solutions for the

aluminium industry.

The company initially operated in the electric industry, with the design, construction and installation of full or partial

systems.

– more than 50 electrical installations completed, including new extrusion presses and revamping operations.

– over 25 installations up and downstream from press. Over the years, we developped a new business brench: special tools for

industries, while the software department grew to achieve superior and reliable performance.

reliable controls, programming, software and complete automation solutions for the

aluminium industry.

The company initially operated in the electric industry, with the design, construction and installation of full or partial

systems.

– more than 50 electrical installations completed, including new extrusion presses and revamping operations.

– over 25 installations up and downstream from press. Over the years, we developped a new business brench: special tools for

industries, while the software department grew to achieve superior and reliable performance.

FAQ

1. who are we?

We are based in Brescia, Italy, start from 1994, sell to North America(40.00%),Northern Europe(20.00%),Eastern Europe(15.00%),South Asia(15.00%),South America(5.00%),Africa(5.00%).

There are total about 1-4 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production; each product is tested and verified.

Always final Inspection before shipment;

3.what can you buy from us?

Special tools for metal industry: scanner for sensor positioning, metal impact detector, rolling mill application, liquid nitrogen die cooling application, quench application for aluminium profile.

4. why should you buy from us not from other suppliers?

We have 40 years experience of automation and tools for production plant. We

are focused on safety and resources optimization. We offer flexibility, short supply chain and customization.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,Credit Card,PayPal;

Language Spoken:English,Portuguese,French,Italian

We are based in Brescia, Italy, start from 1994, sell to North America(40.00%),Northern Europe(20.00%),Eastern Europe(15.00%),South Asia(15.00%),South America(5.00%),Africa(5.00%).

There are total about 1-4 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production; each product is tested and verified.

Always final Inspection before shipment;

3.what can you buy from us?

Special tools for metal industry: scanner for sensor positioning, metal impact detector, rolling mill application, liquid nitrogen die cooling application, quench application for aluminium profile.

4. why should you buy from us not from other suppliers?

We have 40 years experience of automation and tools for production plant. We

are focused on safety and resources optimization. We offer flexibility, short supply chain and customization.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,Credit Card,PayPal;

Language Spoken:English,Portuguese,French,Italian

Похожие товары

1700 мм большой размер Шэньчжэнь 3d принтер УФ смолы с 2 года гарантии

Автоматическая машина для трафаретной печати кофейных чашек

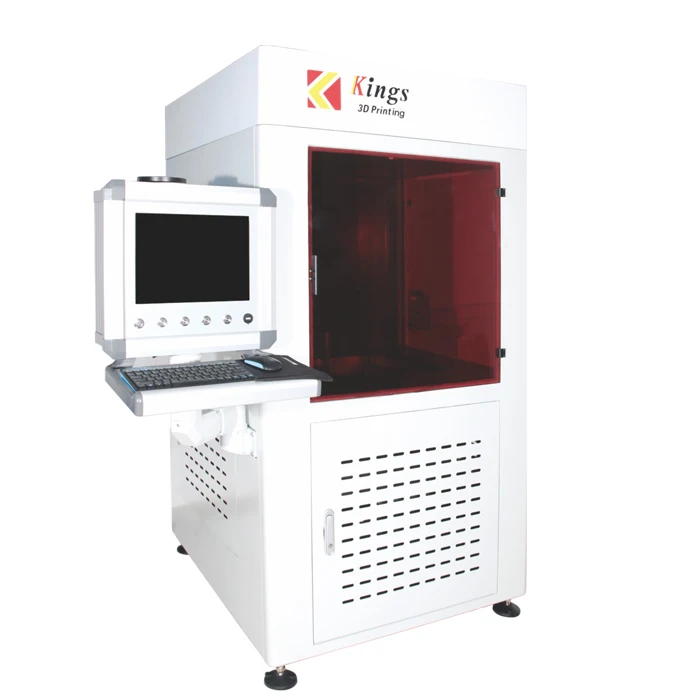

Профессиональный промышленный SLA 3D принтер 300*300*300 мм, размер печати, Высокая точность, Стоматологическая модель, печатная Фотополимерная жидкость

10 000,00 $ - 12 000,00 $

Модель мотоцикла, 3D принтер, самый популярный SLA300 с лазером нм

18 000,00 $ - 23 000,00 $

Литье из фотополимера потерянного воска, смола, другие названия и использование SLA для 3D-принтера, Литейный полимер

Kings650 Pro промышленный SLA 3D принтер для автомобиля

80 000,00 $ - 120 000,00 $

Водонепроницаемый миниатюрный задний медный велосипедный мотоцикл, велосипедный прицеп, автомобиль, прочие лапы, мотоциклетный светодиодный задний фонарь, задний фонарь

20,00 $ - 24,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $