Высококачественные масляные уплотнения DLSEAL Заводские гидравлическое оборудование плавающие

- Категория: >>>

- Поставщик: GUANGDONG DLSEALS TECHNOLOGY CO. LTD.

Сохранить в закладки 11000000988855:

Описание и отзывы

Характеристики

Oil seal

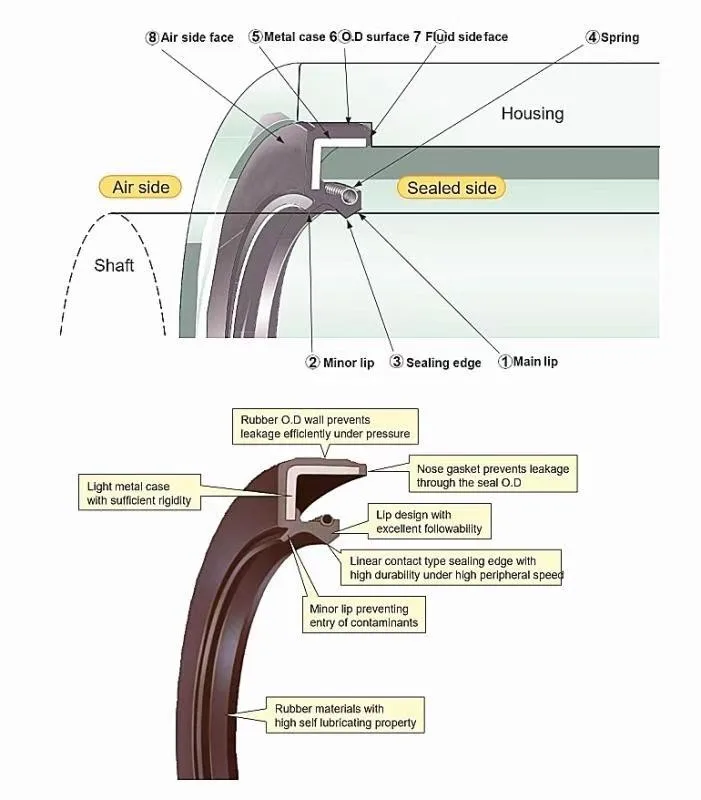

The function of the skeleton oil seal is to isolate the parts that need lubrication from the output parts in the transmission parts, so as not to let the lubricating oil leak. It is usually used in the transmission parts.

The rotary shaft is a rotary shaft lip seal. The skeleton acts as a reinforcing steel bar in concrete members and keeps the shape and tension of the oil seal. According to the skeleton type, it can be divided into internal skeleton oil seal, external skeleton oil seal, and internal and external skeleton oil seal. The skeleton oil seal is made of high-quality nitrile rubber and steel plate, with stable quality and long service life. Widely used in automobile, motorcycle crankshaft, camshaft, differential, shock absorber, engine, axle, front and rear wheels, and other parts.

SIZE | SIZE | SIZE | SIZE | SIZE |

35*54*7 | 44*57*9 | 53*70*9 | 63*92*10 | 72*95*10 |

36*56*7 | 45*56*7 | 54*72*8 | 64*93.3*9 | 73*98*12 |

37*50*6 | 46*58*5 | 55*70*8 | 65*81*7 | 74*96*7 |

38*50*12 | 47*58*7 | 56*76*6 | 66*86*9 | 75*90*13 |

38*50*12 | 48*63*10 | 57*71*7 | 67*88*9 | 76*93*10 |

40*50*6 | 49*63*9 | 58*72*8 | 68*82*10 | 76*93*10 |

41*54*8 | 50*62*12 | 59*72*12 | 69*92*14 | 80*95*8 |

42*52*4 | 51*70*9.5 | 60*72*9 | 70*87*7 | 80*95*8 |

43*55*6 | 52*67*6.7 | 62*75*7 | 71*88*8 | 90*105*12 |

And we can also custom the size of your requirements.

Please contact us to tell me your request.

Other material of oil seal: Silicone, NBR, Metal & Stainless Steel, PTFE, etc.

Production equipment: includes vacuum vulcanizing machines, large-scale flat vacuum vulcanizing machines,

rubber machines, CNC machine tools, temperature-controlled ovens, and detectors.

Application\tHigh-pressure hydraulic seal auto rubber oil seal:

1. Fluid system (static & dynamic)

2. Hydraulic system (dynamic)

3. Pneumatic system (dynamic)

4. Oil or grease media sealing

5. Water media sealing

6. automobile, motorcycle, industry, agricultural machinery, truck, buses, trailers,

exercise equipment.

DLseals standard sizes of Galvanized Copper Washers metal gaskets Dowty seals Bonded Seals

TC NBR Oil seal

It has good heat resistance, wear resistance, resistance to various lubricating oils, greases, oil and gas mixtures, etc., suitable for temperatures of -30 ~ 120 degrees Celsius, but can not be phosphate ester hydraulic oil and gear oil containing extreme pressure additives Used in the performance of gasoline and low aniline point mineral oil.

DLSEALS Different Type Oil Seal | ||||||||

Type | Material | Lip | Spring | Feature | ||||

TC | NBR & FKM | Double Lips | Single | Metal Coverd Rubber | ||||

TB | NBR | Double Lips | Single | Metal Case | ||||

TA | NBR | Double Lips | Single | Metal Case | ||||

SC | NBR & FKM | Single | Single | Double Metal Shell | ||||

SB | NBR | Single | Single | Metal Case | ||||

SA | NBR | Single | Single | Double Metal Shell | ||||

DC | NBR | Double Lips | Double | Double Springs | ||||

VC | NBR & FKM | Single | Without | Metal Coverd Rubber | ||||

VB | NBR | Single | Without | Metal Case | ||||

TCV | NBR | Double Lips | Single | High Pressure | ||||

TCN | NBR | Double Lips | Single | High Pressure | ||||

PTFE | PTFE | Single & Double Lips | Without | Stainless steel | ||||

HTCL | NBR & FKM | Double Lips | Single | Inside thread L | ||||

HTCR | NBR & FKM | Double Lips | Single | Inside thread R | ||||

DLSEALS provides various types of oil seals for industrial, automotive, motorcycle and other machinery, OEM and custom are available! | ||||||||

MATERIAL | TEMP | ADANTAGES | LIMITATION | |||||

Nitrile Rubbrt (NBR) | -40~125℃ | Good oil and fuel resistance High tensile strength Low swelling in water | Poor weather and ozine resistance Poor resistance against polar lkuids Poor resistance against clhydrocarbon Poor resistance against aromatic fluids | |||||

Fluorinated Rubber (FKM) | -20~250℃ | The resistance against oil and fuels is better than other types The only highly elastic rubber whice is resistance to aromatci and chlornated hydrocarbons Exccllcent hcat resistance Exccllcent weather and ozonc resistance Exccllcent acid resistance Low swelling in water | Limited tensile and tear strength Limited wear resistance High compression set in hot water Poor resistance to polaric solvents | |||||

Polyacrylate Rubber (ACM) | -25~150℃ | Good oil and fuels resistance Good weater and ozone resistance | Not usable in contact with water and water solutions Limited cold flexibility Limited tensile strength and tear resistance Poor wear reisistance Poor resistance against polar and aromatic and chlorinared hydrocarhons | |||||

Silicone Rubber (VQM) | -60~225℃ | Best heat resistance of all rubber types Excellent low temp resistance of all rubber types Excellent weather and ozone resistance | Poor tensile and tear strength Poor wear resistance Sensitive to hydrolysis Poor resistance against aromatic oils and oxidized mineral oils Poor diffusion resistance | |||||

DLSEALS OIL SEAL More materials, EPDM, SBR, SR, CR, HNBR, etc. Please contact us. | ||||||||

We are manufacturer.We are based in Guangdong, China, start from 2010,sell to Domestic Market(33.00%),North America(15.00%),South America(10.00%),Western Europe(8.00%),Eastern Europe(6.00%),Southern Europe(6.00%),Southeast Asia(5.00%),Mid East(5.00%),Northern Europe(5.00%),Oceania(2.00%),South Asia(2.00%)

2. how can we guarantee quality?

Always a pre-production sample before mass production;

PTFE Seals/Oil Seals/O Rings/Rubber Seals/Plastic Seals

stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

6.Do you provide samples ? is it free or extra ?

Похожие товары

Китайский поставщик, производитель автозапчастей, двигатель NBR, уплотнение штока клапана, сальник клапана, сальник, резиновый поставщик на заказ

32500 сальник колеса Ступицы CR для 30009,30008 колес грузовика

TB масляное уплотнение резиновый каркас масляное уплотнение от производителя прямо под заказ Китай

Китайский комплект, Уплотнители для цилиндров, механические резиновые масляные уплотнения, гидравлические уплотнения для тягачей

SNAK Factory TC 360*400*20 вал сальник Tc резиновая покрытая двойная губа Nbr Fkm промышленное уплотнение Китай сальник производитель

Масляное Уплотнение TC 32*52*8 под заказ, высокое качество, заводской поставщик, китайский производитель, резиновое уплотнение вала

Китайский производитель, высокопроизводительный каркасный резиновый сальник 28*47*10 мм, сальник TC

Новые поступления

Новинки товаров от производителей по оптовым ценам