100 Вт Mopa JPT цветная 3d Динамическая волоконно лазерная маркировочная машина

- Категория: Industry Laser Equipment >>>

- Поставщик: Jinan Hitec Machinery Co. Ltd.

Сохранить в закладки 11000001295971:

Описание и отзывы

Характеристики

Fiber laser marking machine applied Industries

Curved surface marking:

In the traditional 2D marking machine, the workpiece must be placed on the same plane, and the processing surface must also be on the same plane, in order to achieve the marking once formed, and the surface marking cannot be completed. The 3D laser marking machine can quickly change the laser focal length and laser beam orientation, and can achieve curved surface marking that cannot be done in 2D.

Deep carving:

The traditional 2D marking has inherent defects when deep carving the object surface. As the laser focus moves upward during the engraving process, the laser energy acting on the actual surface of the object will drop sharply, which seriously affects the effect and efficiency of deep engraving. Therefore, it is necessary to move the lifting table at a specific height every specific time during the engraving process to ensure the laser surface gathering effect.

The 3D laser marking machine has greatly reduced the surface flatness requirements of the processed objects. In the process of deep carving, it not only ensures the effect, but also improves the efficiency, and the processable effect is more abundant.

The 3D laser marking machine adopts the front focusing optical form and uses larger X and Y axis deflection lenses, so it can allow a larger transmitted laser spot, better focusing accuracy and better energy effect; 3D laser marking machine compared with the 2d laser marking machine, the marking scale can be larger when gathering precision operations. The 3D laser marking machine can achieve one-time marking on the cylinder within a specific arc, which greatly improves the processing power.

In the industrial production process, the appearance of many parts is irregular, and the height of some parts is quite different. 2D marking processing is difficult to meet the needs. The advantages of 3D laser marking will gradually become more prominent.

Marking Materials

Fiber lasers can be used for a wide variety of applications, from industrial traceability to branding, on materials such as steel, copper, aluminum, plastic, ceramic, and brass..

Fiber laser marking machine parameter | ||||||

Item | Core parameters | Configurable parameters | ||||

Power | Engraving area | Applicable material | laser source power | |||

1 | 200x200mm | Metal/ plastic/ Crystal | 50w 60w 80w 100w | |||

2 | 600x600mm | |||||

Related keywords | fiber laser marking machine, laser marking machine, metal laser marking machine, cnc fiber laser marking machine, laser marker | |||||

Laser Wavelength | 1064nm | 1064nm | ||||

Minimum Line Width | 0.015mm | 0.015mm | ||||

Minimum Character | 0.2mm | 0.2mm | ||||

Repeated Precision | ±0.003mm | 0.2mm | ||||

Software | 3D lenmark | 3D lenmark | ||||

Life-span of Fiber Laser Module | Beam Quality | 3D lenmark | ||||

Beam Quality | M2 <1.6 | M2 <1.6 | ||||

Focus Spot Diameter | <0.01mm | <0.01mm | ||||

System Operation Environment | Windows XP / Windows 7 / Windows 8 | XP/ Win7/Win8 etc | ||||

Cooling Mode | Air cooling--Built-in | Air cooling--Built-in | ||||

Temperature of Operation Environment | 15℃~35℃ | 15℃~35℃ | ||||

Power Stability (8h) | <±1.5%rms<±1.5%rms | <±1.5%rms | ||||

Voltage | 220V / 50HZ / 1-PH or 110V / 60HZ / 1-PH | |||||

Power Requirement | <500W | |||||

Computer Requested | There will be one PC with the machine | There will be one PC with the machine | ||||

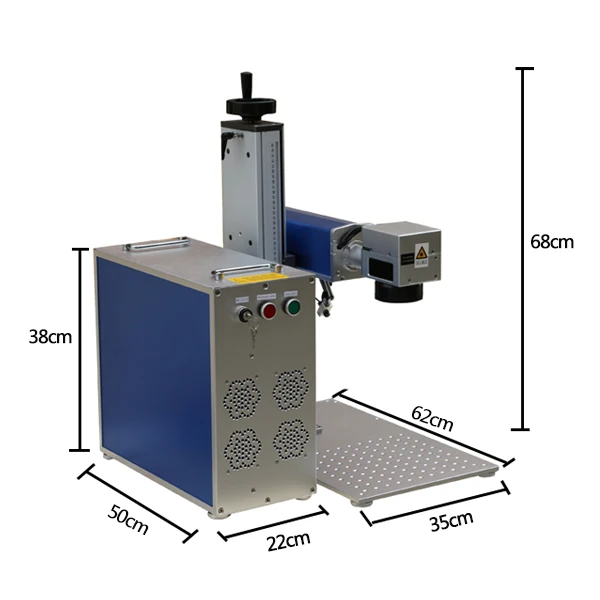

Dimension (L*W*H) | 900mm*880mm*1560mm | |||||

Package Size | 980mm*950mm*1650mm | |||||

Gross Weight | 50KG | 70KG | ||||

Net Weight | 60KG | |||||

Optional (Not free of charge) | Rotary Device, Moving Table, other customized Automatic Matching System | |||||

3D Fiber laser marking machine advantage than 2D

1. Variable focal length to realize three-dimensional marking

Because 3D marking can quickly change the laser focal length and laser beam position, it becomes possible to mark curved surfaces that cannot be achieved in 2D.

2. More suitable for deep carving

Traditional 2D marking has inherent defects in deep engraving of the object surface. As the laser focus moves up during the engraving process, the laser energy acting on the actual surface of the object will drop sharply, which seriously affects the effect and efficiency of deep engraving.

3D marking for deep engraving processing does not have the above problems.

3. Larger range and finer light effects

3D marking can be divided into front focus and back focus. When the front focus mode is used, the main purpose is to achieve a larger marking range.

4. In the same plane, black and white marking can be realized, and even multi-color marking can be achieved, with richer effects

Surface blackening, such as anodized aluminum, usually uses higher-frequency pulses at appropriate energy to mark with a certain defocus. The defocus distance significantly affects the energy distribution and color effect of the laser on the surface of the material.

Company Information

Established in the year 2002,An ISO 9001 Firm.We are manufacturer and deverlops of the high technology machines.Hitec products are used in a wide variety of industries,markets and applications thoughout all over the world.Hitec is highly committed to offering the most advanced,capable and efficient manufacturing technology backed by unsurpassed service and support.

We offer cnc wood router,cnc laser,cnc plasma,cnc parts.

Cnc Laser Engraving and cutting

Inclued :co2 laser cutting machine,metal laser cutting machine,fiber laser cutting machine,metal&nometal laser cutting machine

Cnc Wood Router

Inclued :2&3D cnc router,3axis atc cnc router,4axis cnc router,5axis cnc router also the hot sale advertising cnc router.

Cnc Marking Machine

Included: fiber laser marking machine,co2 laser marking machine ect.

our products can meet the needs of users to the greatest extent, and at the same time make the customer's investment play the

largest comprehensive economic benefit.

user's reasonable temporary needs;

3. Collaborate friendly with users to deliver qualified products.

Except the damage is artificial, we are responsible for offering the fittings free of charge during the guarantee period, but you

need to send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. Out of

the guaranteed period, should the parts required to be repaired or replaced, if any, the parts will be charged.

Q1: I need a laser machine, can you give me some suggestions?

Sure, please send us inquiry and tell us your processing materials,size and thickness, we will recommend you suitable model.

Q2: which kind of materials can be processed on this machine?

Plastic and Metal materials, such as ss, cs, aluminum, copper and so on.

Q3: Are you a factory or trading company?

We are the manufacturer and we have over ten years factory experience .And we welcome you to visit us.

Q4: How long is the delivery time for this laser machine?

For standard machines, it would be 5-7 days; For non-standard machines and customized machines according to client s specific requirements, it would be 7 to 10 days.

Q5: How should I pay for my order ?

You can do 30% prepayment at first, then we will start to make production. After finish production,shipping,then you can pay that 70% balance.

Похожие товары

Держатель сопла керамический волоконный лазер 0936678/0260432/1755673/1906032 подходит для лазерной режущей машины Trumpf импортирован из

Оптоволоконный диодный лазер 940nm 10 Вт для волоконного лазера

Лидер продаж, лазерная трубка RECI CO2 W серии 75 Вт 90 Вт 100 Вт 130 Вт 160 Вт 180 Вт для лазерной резки, гравировального станка

HS LASER 2023 новый дизайн ручной лазерный сварочный аппарат с проволочной

JNKEVO портативный лазерный гравер JPT Raycus CNC Волоконно-Лазерная глубокая гравировка машины SS CS Металл 20 Вт 30 Вт 50 Вт стол 3D

20 Вт 30 50 60 Mopa Jpt волоконно-лазерная маркировочная машина для продажи из нержавеющей стали ручная лазерная RAYCUS лазерный

JQ-HW1500 волоконный лазерный сварочный аппарат автоматический пистолет ручной сварочный аппарат для нержавеющая сталь полировки металла

Новые поступления

Новинки товаров от производителей по оптовым ценам