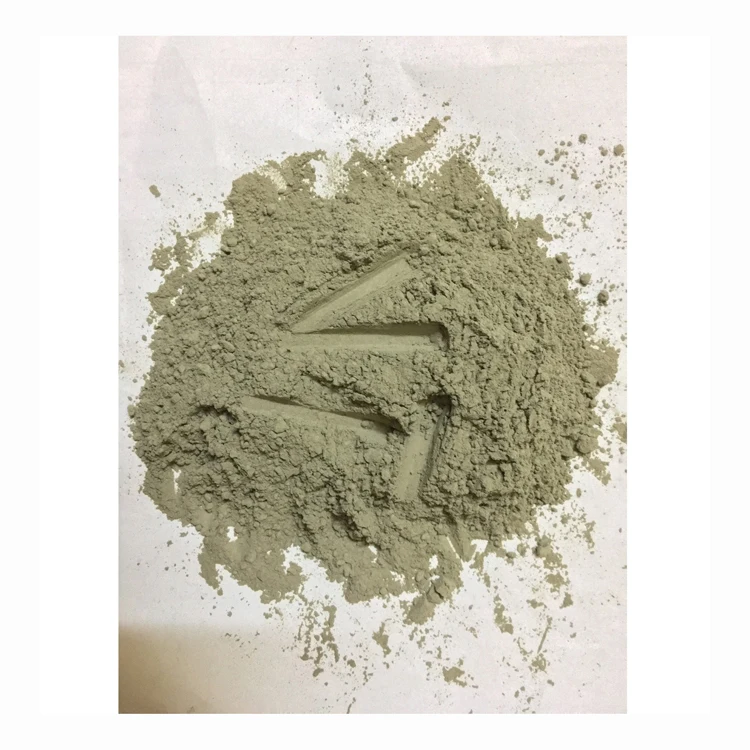

Высокое качество #52 5 белый Портленд цемент силикат в терраццо каменный материал украшения

- Категория: >>>

- Поставщик: Plug In ApsPlug Aps

Сохранить в закладки 11000014333610:

Описание и отзывы

Характеристики

Products Description

Portland cement is the most commonly used type of cement in construction. It's a fine powder, primarily made of limestone, clay, and other materials such as iron ore or shale. Here are some key points about Portland cement and its applications:

1. Basic Composition: Portland cement is composed of calcium silicates, aluminates, and ferrites. The main components are calcium oxide (CaO), silicon dioxide (SiO2), aluminum oxide (Al2O3), and iron oxide (Fe2O3). These compounds are combined through a process called calcination, where raw materials are heated to high temperatures in a kiln.

2. Manufacturing Process: The manufacturing process of Portland cement involves quarrying raw materials such as limestone, clay, and shale. These materials are crushed, ground into a fine powder, and then heated in a rotating kiln at temperatures around1450°C (2640°F). The resulting clinker is then ground into a fine powder to produce Portland cement.

3. Types of Portland Cement: There are several types of Portland cement, each with specific properties suited for different

applications. These include Type I (general-purpose cement), Type II (moderate sulfate resistance), Type III (high early

strength), Type IV (low heat of hydration), and Type V (high sulfate resistance).

4. Applications in Construction: Portland cement is a key ingredient in concrete, mortar, and grout, which are widely used in construction. Concrete, a mixture of Portland cement, aggregates (such as sand and gravel), and water, is the most common building material used for foundations, walls, floors, pavements, and infrastructure projects.

Product Name: | Portland cement | |||

Place Of Origin: | Denmark | |||

Grade: | A | |||

Why Choose Us? | High Quality Best Price Fast Delivery 24/7 Available |

Our Advantages

In modern day markets, quality has become a major economic factor. Customers not only require a fast and efficient delivery of data, but also 100% accuracy of the data provided. Moreover, professional services and an excellent customer support are the basis of any customer relationship. To verify our commitment to consistently meeting and exceeding customers' expectations, we submit ourselves to critical external audits for review and certification of our services.

Product packaging

Product Shipping

FAQ

Похожие товары

Supply of White Cement Portland Construction for Exterior Wall Decoration Quick Drying Repair

Натуральный биоэкологичный продукт осушитель на основе известкового гипса для внутреннего и наружного использования сохранения наследия

4,39 $

Производство и обработка белого цемента Портленд белый цемент здания наружная стена быстросохнущая промышленного класса

Обычный Портленд Cemento (OPC TYPE I)

Производитель Китай алюминат кальция цементный CA-70 CA-80 для литейного цемента с высоким содержанием глинозема огнеупорного

0,35-0,45 $

Производитель Китай алюминат кальция цементный CA-70 CA-80 для литейного цемента с высоким содержанием глинозема огнеупорного

0,70-0,78 $

Обычный портланд цемент серый цементный 32 5 42 52 цена

200,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $