Хорошая водонепроницаемость эластомерный лист из вспененного ПВХ для домашней сантехнической системы теплоизоляция

- Категория: >>>

- Поставщик: Tianjin Huayue International Trade Co. Ltd.Tianjin Ltd.

Сохранить в закладки 11000017917008:

Описание и отзывы

Характеристики

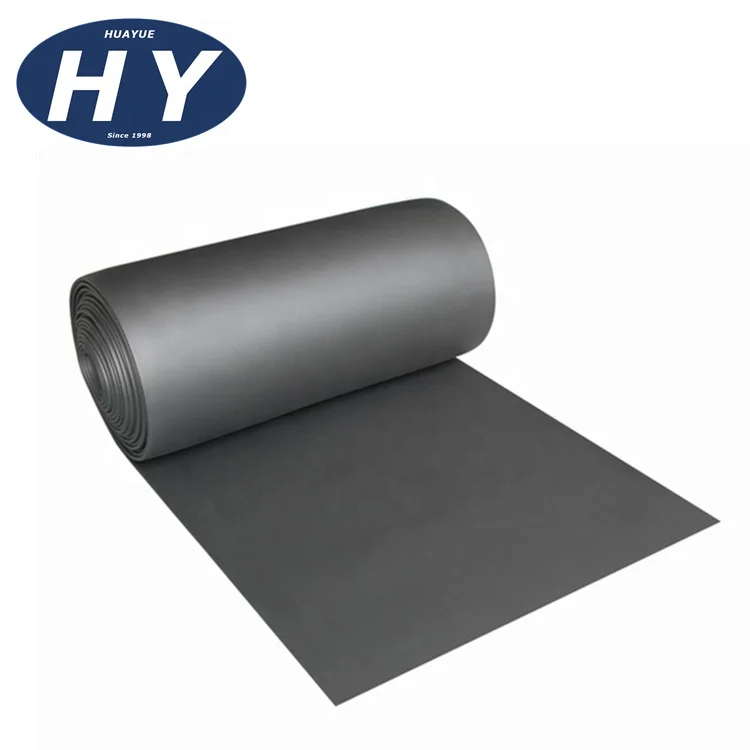

Good Waterproof Property Elastomeric NBR PVC Rubber Foam Sheet For Home Plumbing System Heat Insulation

Product Description

The rubber foam products of our company are produced by imported high-end technology and automatic continuous equipment. We have developed a rubber foam insulation material with excellent performance through in-depth research. The major raw materials we use are NBR/PVC.

The main characteristics are: low density, close and even bubble structure, low thermal conductivity, cold resistance, extremely low water vapor transmissibility, low water absorbtive capacity, great fireproof performance, superior anti-age performance, good flexibility, stronger tear strength, higher elasticity, smooth surface, no formaldehyde, shock absorption, sound absorption, easy to install. The product is suitable for a wide range of temperature from -40℃ to 120℃.

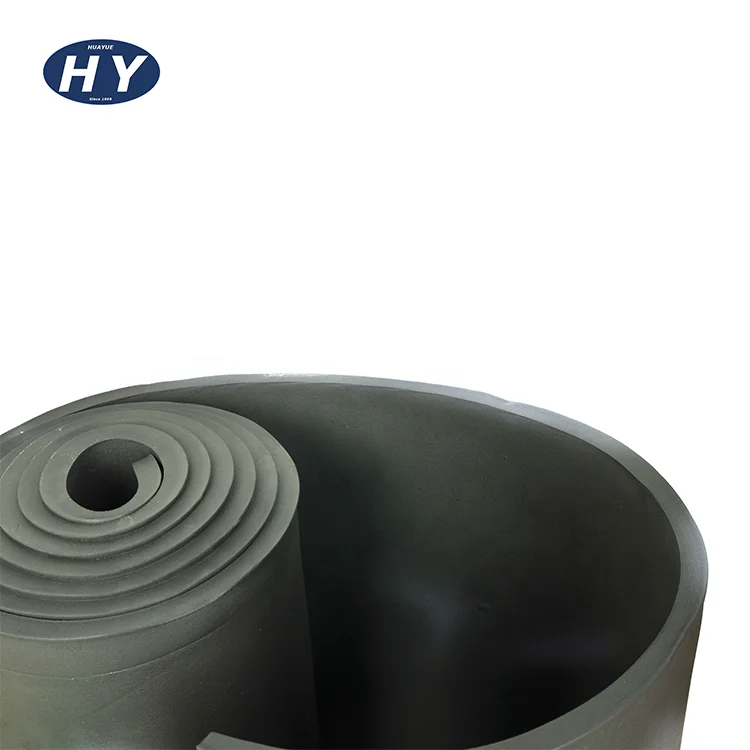

Our Class0/1 insulation is generally black in color, other colors are available upon request. The product comes in tube, roll and sheet form. The extruded flexible tube are specially designed to fit the standard diameters of copper, steel and PVC piping. Sheets are available in standards precut sizes or in rolls.

Specification of Rubber Foam

Technical Data | ||||||||

Item | Unit | Specification | Standard | |||||

Density range | Kg/m3 | 40-85 | GB/T 6343 ASTM D1667 | |||||

Flammability | Oxygen index | % | ≥32 | GB/T 2406 | ||||

SDR | —— | ≤75 | GB/T 8627 | |||||

Fire Rating | —— | Class 0 & Class 1 | BS 476 Part 6 & Part 7 | |||||

Conductivity factor -Average temperature | -20℃ | W/(M·K) | ≤0.030 | GB/T 10294 ASTM C518 | ||||

0℃ | ≤0.032 | |||||||

40℃ | ≤0.036 | |||||||

Water vapor Permeability | Coefficient | g/(m·s·pa) | ≤2.8 X 10-11 | GB/T 17146 | ||||

Factor | —— | ≥10000 | ||||||

Water adsorption ratio in vacuum | % | ≤4 | GB/T 17794 | |||||

Dimension stability (105℃±3℃, 7d) | % | ≤5 | GB/T 8811 ASTM C534 | |||||

Crack resistance | N/cm | ≥3.0 | GB/T 10808 | |||||

Comperssion resilience ratio (Comperssion ratio 50%, Comperssion time 72h) | % | ≥70 | GB/T 6669 | |||||

Anti-ozone (Ozone pressure 202mpa 200h) | —— | Not cracking | GB/T 7762 | |||||

Aging resistance (150h) | —— | Slightly crumpling, no cracks, no pin holes, not eforming | GB/T 16259 | |||||

Flexibility | —— | Excellent | ASTM D1056 | |||||

Temperature | ℃ | -50 — 120 | GB/T 17794 | |||||

Products type | Pipe & sheet | |||||||

Color | Black, gray and other colors | |||||||

Regular size | Pipe: inner diameter 6-108mm Sheet: thickness 10-30mm | |||||||

Packing | PE plastic bags / exported standard carton Diversified packaging to meet your needs | |||||||

Range of specifications of rubber foam sheet insulation

Thickness | 6mm | 10mm | 15mm | 20mm | 25mm | 30mm | 32mm | 40mm | |||||||

Length | 30m | 20m | 10m/16m | 8m/10m | 8m/10m | 8m/10m | 6m | 5m | |||||||

Width | 1m, 1.2m, 1.5m | ||||||||||||||

Note:

1.The above specifications are commonly used specifications. Special specifications are available according to request of customer.

2. Rubber foam sheet and pipe are normally in black. Other colors are available according to requirements of customer.

3. It is recommended to use sheet when outer diameter of pipe exceeds 89mm.

4. Multiple layers packing is recommended where the thickness of heat insulation materials which you need are greater than 25mm.

5. The width of the sheet can be customized to 1-2 meters according to customer's requirements.

1.The above specifications are commonly used specifications. Special specifications are available according to request of customer.

2. Rubber foam sheet and pipe are normally in black. Other colors are available according to requirements of customer.

3. It is recommended to use sheet when outer diameter of pipe exceeds 89mm.

4. Multiple layers packing is recommended where the thickness of heat insulation materials which you need are greater than 25mm.

5. The width of the sheet can be customized to 1-2 meters according to customer's requirements.

Table of required thickness comparison for installation

(Due to the different environmental conditions in each region, the following data is for reference only.)

Environmental conditions | Dimension of heat-preservation pipe | Suitable thickness at temperature of piping(mm) | ||||||||||

Temperature | Relative Humidity | Inch | Millimeter | 13℃ | 7℃ | 3℃ | -15℃ | |||||

26.5℃ | 50% | 3/8-3 | 10-76 | 10 | 10 | 10 | 15 | |||||

3-5 | 76-127 | 15 | 15 | 15 | 15 | |||||||

5-10 | 127-254 | 15 | 15 | 15 | 20 | |||||||

29℃ | 70% | 3/8-3 | 10-76 | 10 | 15 | 15 | 20 | |||||

3-5 | 76-127 | 15 | 15 | 15 | 20 | |||||||

32℃ | 80% | 5-10 | 127-254 | 15 | 15 | 15 | 25 | |||||

3/8-5 | 10-127 | 15 | 15 | 20 | 20 | |||||||

5-10 | 127-254 | 20 | 25 | 25 | 35 | |||||||

32℃ | 85% | 3/8-1.5 | 10-38 | 20 | 25 | 30 | 45 | |||||

1.5-3 | 38-76 | 20 | 30 | 30 | 50 | |||||||

3-5 | 76-127 | 20 | 30 | 35 | 60 | |||||||

5-10 | 127-254 | 25 | 30 | 40 | 60 | |||||||

>10 | >254 | 30 | 40 | 45 | 70 | |||||||

32℃ | 90% | 1/8-0.5 | 3-13 | 25 | 32 | 35 | 45 | |||||

0.5-2.5 | 13-64 | 30 | 35 | 45 | 60 | |||||||

2.5-5 | 64-127 | 30 | 35 | 45 | 65 | |||||||

5-10 | 127-254 | 35 | 45 | 50 | 75 | |||||||

>10 | >254 | 35 | 50 | 60 | 75 | |||||||

Note: Factors need to considered when choosing the thickness of insulation material

1. The higher the environmental temperature is, the thicker the material is.

2. The higher the relative humidity is, the thicker the material is.

3. The lower the temperature of the medium is, the thicker the material is.

4. The larger the daimeter of the pipe, the thicker the material is.

1. The higher the environmental temperature is, the thicker the material is.

2. The higher the relative humidity is, the thicker the material is.

3. The lower the temperature of the medium is, the thicker the material is.

4. The larger the daimeter of the pipe, the thicker the material is.

Application of Rubber Foam Sheet/Pipe

Rubber Foam insulation materials are widely in multiple scenes for thermal insulation and noise reduction, which are used in various pipes and equipment, such as central air conditioning, air conditioning units, construction, chemical, medicine, electrical appliances, aerospace, auto industry, thermal power etc.

Company Profile

Why Choose Us

1.Better Product Performance

Our products have high oxygen index content, good fireproof performance;

Using fine control micro-foaming technology, makes the rubber foam products have the excellent sound absorption and noise reduction, good anti-shock effect;:

Our products were called "Non-cracking rubber", the unique process and technology make the product flexible and easy to construct.

2.Long Service Life

The products' service life can reach more than 25 years, far better than other suppliers.

3.Safety and Environmentally Friendly

No fiber dust, no formaldehyde, no odor, more healthy and environmentally friendly, more safe to use.

2.Long Service Life

The products' service life can reach more than 25 years, far better than other suppliers.

3.Safety and Environmentally Friendly

No fiber dust, no formaldehyde, no odor, more healthy and environmentally friendly, more safe to use.

Certifications

Rubber foam heat insulation material of our company has obtained FM and ASTM certification of the US, BS476 part 6 & part 7, and ISO14001, ISO9001, OHSAS18001 certificate etc.

Quality Control

Huayue maintains a stringent system of QC, in all its operation by its professional QC staff. We have 6 quality control engineers and test chemists.

We have our own test laboratory. HUAYUE rubber foam heat insulation has been inspected by HUAYUE's Professional Quality Inspectors.

From each batch of raw materials, mid-products to end insulation materials, whole process would be validated by Huayue's Quality Assurance system. This will assure our customers that all materials have been tested and meet our high standards of quality assurance.

Packaging and Shipping

All products will have been strictly quality checked in house before packing. All products will be well packed before shipping. We accept OEM.

FAQ

Q: Are you manufacturer or trade company?

A: We are professional manufacturer of thermal insulation material, more than 22 Years.

A: We are professional manufacturer of thermal insulation material, more than 22 Years.

Q: Do you accept sample order?

A: Sample order is acceptable. We can offer free sample, sample can be sent within 1~3 days after freight payment confirmed.

A: Sample order is acceptable. We can offer free sample, sample can be sent within 1~3 days after freight payment confirmed.

A: We are in compliance with ISO14001, ISO9001, OHSAS18001 certificate etc. Our products have excellent chemical, physical features and stability.

Q: What services can Huayue provide?

A: * Any inquires will be replied within 0-1 hours.

* We are professional manufacturer and trade company. Welcome to visit our company and factories at any time!

* Any your idea on the packing we can help you to design and put into production. Customized product is available.

* High quality, reasonable and competitive price, fast lead time.

* All products will have been strictly quality checked in house before packing.

* All products will be well packed before shipping. Sample order prepared, about 3-10 days for delivery productions.

* Any your idea on the packing we can help you to design and put into production. Customized product is available.

* High quality, reasonable and competitive price, fast lead time.

* All products will have been strictly quality checked in house before packing.

* All products will be well packed before shipping. Sample order prepared, about 3-10 days for delivery productions.

Q: What is Huayue's inspection process for Rubber Foam?

A: Raw Material Inspection - Production Process Inspection - Factory Inspection - Parallel Sample Tracking System.

Q: What’s the delivery time of 1x40HQ container loading order?

A: Within 3-20 days after receipt of prepayment.

We'll give you prompt reply within 0-1 hours!

Похожие товары

Металлизированная полиэфирная пленка/алюминиевая катушка теплоизоляция

Многофункциональный звукоизоляционный изоляционный лист с клеем

Изоляция из микрофибры стекловолокна 25 мм промышленный современный дизайн полиэтиленовый материал

0,48-0,56 $

Алюминиевый теплоотражательный кровельный изоляционный xpe пеноматериал

Влагостойкий огнестойкий класс A1 CE сертификация рулон из крафт-бумаги стекловолокна для потолочной теплоизоляции

0,60-1,00 $

70% Visible Light Transmission Heat Insulation Function Film and Reflective Solar Films

5,00-6,00 $

Xps пенопластовые панели для крыши защищенные от шума 50 мм панель из высокоплотной стекловаты изоляции воздуховодов

0,35-0,37 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

OEM пользовательские пружинные зажимы из нержавеющей стали сверхмощный кронштейн для монтажа батареи 9 В прецизионное изготовление листового металла на заказ штамповка

Оптовая продажа двусторонняя велюровая хлопковая Панама для рыбаков взрослых Детская вышивка с логотипом на заказ весенне-летние Мультяшные банты

3-3,95 $

Лучшее качество низкая цена без ГМО шелухи белые семена

Полезные Порошковые напитки подходящие для

7,52-13,23 $

Многофункциональный портативный мини-ридер для нарезки рыбы швейная машина игольчатый ридер набор иголок

Фингель цветок лотоса плавающий свет со светодиодной подсветкой

Квадратная бумажная коробка для попкорна

0,04-0,06 $