QIPANG медная трубка выпрямление и автомат для резки трубы чистого реза с управлением PLC

- Категория: >>>

- Поставщик: Shanghai Qipang Industrial Co. Ltd.

Сохранить в закладки 1100014804693:

Описание и отзывы

Характеристики

Product Description

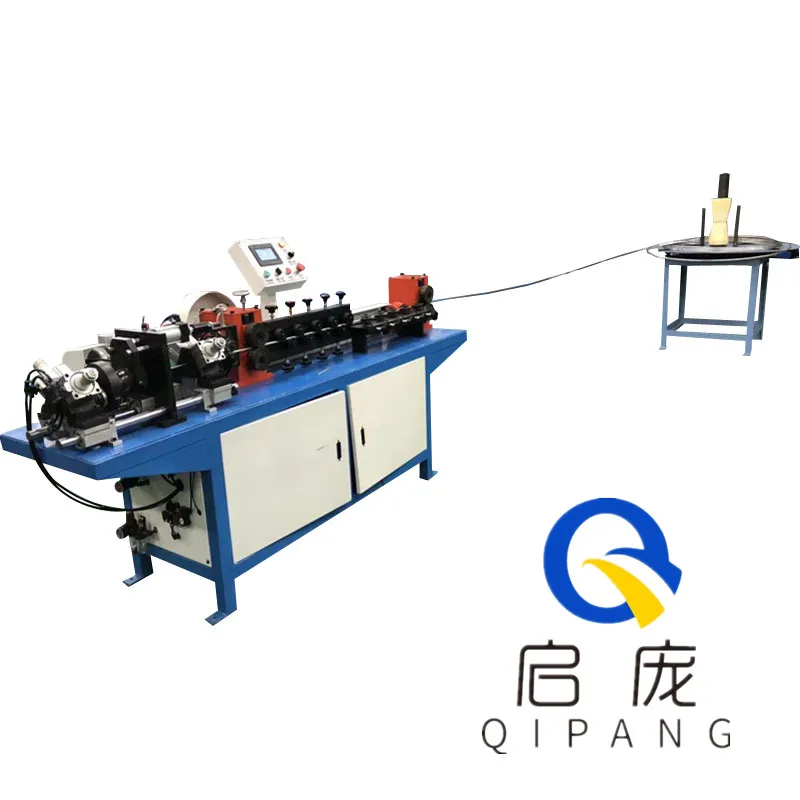

QIPANG Copper tube straightening and cutting machine for pipe clean cut with PLC control

Product Application:

The chipless tube straightening and cutting machine is special designed for copper and aluminum tube process, which is mainly used for tube blanking before tube bending or welding process of condenser and evaporator. Compare to normal design with two-half clamping die, we design the clamping die in three parts according to lathe chuck structure, which can minimize the tube distortion during cutting, and the clamping die changing / adjustment will be more easier.

The chipless tube straightening and cutting machine is special designed for copper and aluminum tube process, which is mainly used for tube blanking before tube bending or welding process of condenser and evaporator. Compare to normal design with two-half clamping die, we design the clamping die in three parts according to lathe chuck structure, which can minimize the tube distortion during cutting, and the clamping die changing / adjustment will be more easier.

Main Features:

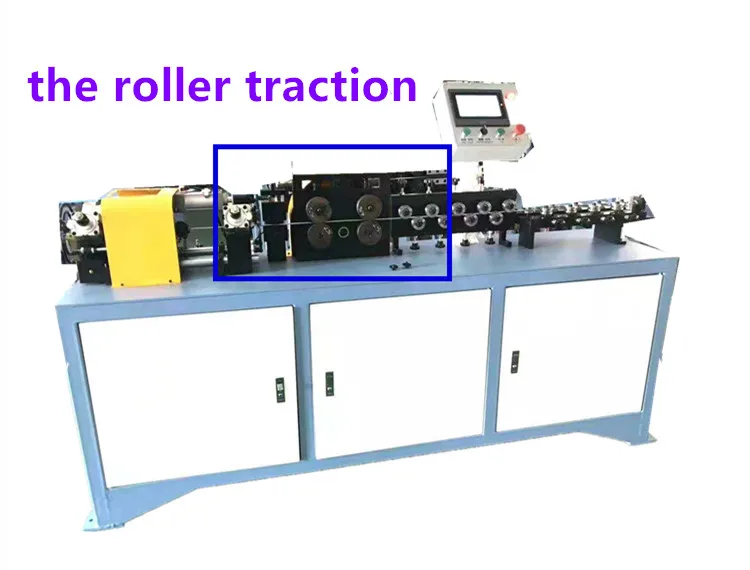

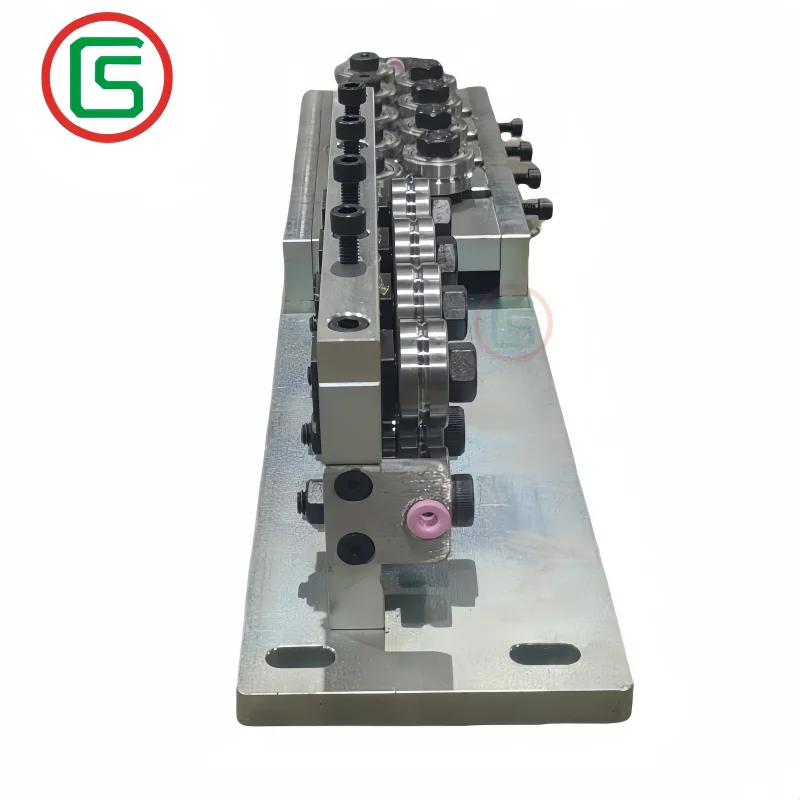

◆Three-part clamping die to minimize tube distortion, get smooth cutting end surface.

◆High accuracy concentricity ensures to get good welding quality in following process.

◆Chipless cutting with 360° rotary cutting and stretching with two points clamping.

◆ Straightening wheel Nylon and “U” shape rubber belt to avoid scratch on tube surface

◆Three-part clamping die to minimize tube distortion, get smooth cutting end surface.

◆High accuracy concentricity ensures to get good welding quality in following process.

◆Chipless cutting with 360° rotary cutting and stretching with two points clamping.

◆ Straightening wheel Nylon and “U” shape rubber belt to avoid scratch on tube surface

Specification

Parameter | Data |

Tube Material | Copper / Aluminum / Bundy tube |

Tube Diameter | 4-20mm |

Cutting Length | >50mm |

Work Speed | 0~60m/min, adjustable by Inverter |

Cutting Tolerance | 0.5mm/1m |

Control System | PLC control / HMI |

Motor Power | 1.12KW |

Electric System | 380V, 50Hz, 3Phae (Customized) |

Dimension | 2300 x 650 x 1300 mm |

Weight | 460 KG |

Detailed image:

Packing & Delivery

QIPANG Copper tube straightening and cutting machine for pipe clean cut with PLC control

Size: 2300 x 650 x 1300 mmWeight: 460kg

Packaging Details:The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

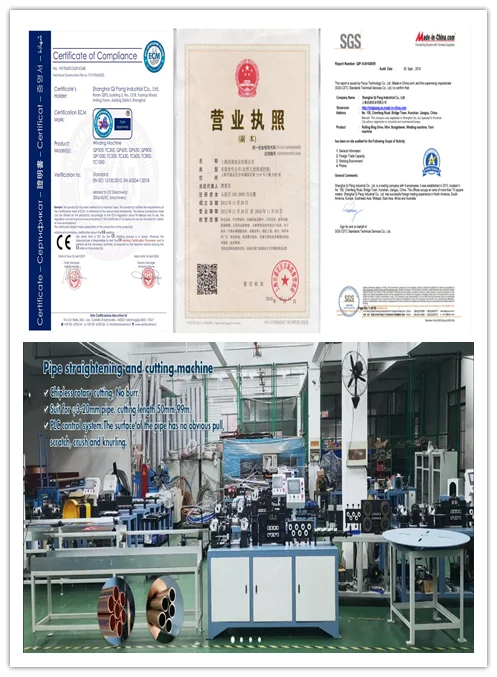

Company Profie

Related products :

Title goes here.

QIPANG Copper tube straightening and cutting machine for pipe clean cut with PLC control

FAQ

Q1: Are you a factory or trading company?

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

Q2: How does the factory ensure products quality?

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

Q3:How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone,webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q4: What are your payment terms?

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading department.

Q2: How does the factory ensure products quality?

With Nearly 16 years experience in manufacturing winding machine, we have our own technology develop department and testing department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers to assemble and test machine.

Q3:How about your after-sale service?

We have a professional technology supporting team for your timely services. You can get the help you need in time by telephone,webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be offered.

Q4: What are your payment terms?

100%TT or prepaid 50% , balance 50% before shipping.

Q5: How can I get my order? How can I know you sent the goods?

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

Q6 : Will you send the installed machine or machine parts?

We will install the machine and test the machine before delivery. And the machine can be used directly after receiving the machine.

Q7: Will you provide operation guidance for us?

We will send the instruction book with the machine and send you a video about how to operate the machine.

Q8 : How long is the warranty period?

12 months warranty, we will send you free spare parts by air within one week if there are any quality problems.

Q5: How can I get my order? How can I know you sent the goods?

We will send the goods by UPS, DHL, FedEx or sea shipment. After we sent the goods, we will give you the tracking number or other relative files for checking.

Q6 : Will you send the installed machine or machine parts?

We will install the machine and test the machine before delivery. And the machine can be used directly after receiving the machine.

Q7: Will you provide operation guidance for us?

We will send the instruction book with the machine and send you a video about how to operate the machine.

Q8 : How long is the warranty period?

12 months warranty, we will send you free spare parts by air within one week if there are any quality problems.

QIPANG Copper tube straightening and cutting machine for pipe clean cut with PLC control

Aimee

phone/whatsapp/ skype: +86 18913219907

Похожие товары

Гидравлический инструмент для выпрямления проволоки

Оборудование для металлических стальных стержней, ручная машина для резки арматуры, машина для выпрямления стержней из чистой медной проволоки

89 645,15 ₽ - 97 205,58 ₽

1-6 мм стальная проволока выпрямление и резка машины управление с помощью ПЛК система резки длина

1-6 мм стальная проволока выпрямление и резка машины управление с помощью ПЛК система резки длина

Оборудование для выпрямления металла, подходящее для выравнивания металлических деталей вала и стержня

1 706 537,04 ₽ - 1 717 476,38 ₽

Завод по производству Алюминиевой Проволоки Волочильный станок для выпрямления твердой проволоки

30 630,16 ₽ - 31 724,09 ₽

Китай Тайваньская технология прецизионная правильная машина с десятью роликами и для стальных или алюминиевых труб

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $