99% CBD Oil Wiped Film Short Path Molecular Distillation for non stop working

- Категория: >>>

- Поставщик: Zhengzhou Well-Done Group Co. Ltd

Сохранить в закладки 1100014970511:

Описание и отзывы

Характеристики

99% CBD Oil Wiped Film Short Path Molecular Distillation for non-stop working

Introduction:

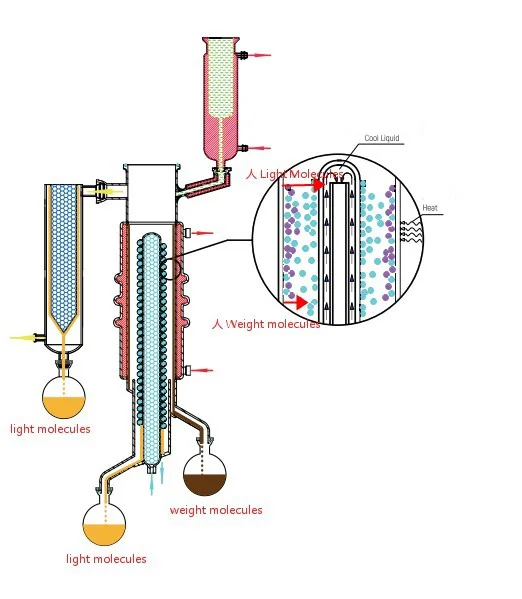

Molecular distillation is a special liquid-liquid separation technology. It is different from traditional distillation by the principle of boiling point difference separation, but by the difference of the average free path of the molecular motion of different substances to achieve separation. When the liquid mixture flows along with the heating plate and is heated, light and heavy molecules will escape the liquid surface and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances will move at different distances after they escape from the liquid surface. After passing through the condensation tube in the main evaporator, light molecules reach the condensation tube and are discharged, while heavy molecules cannot reach the condensation tube and are discharged along with the mixed liquid. In this way, the purpose of material separation is achieved.

Features

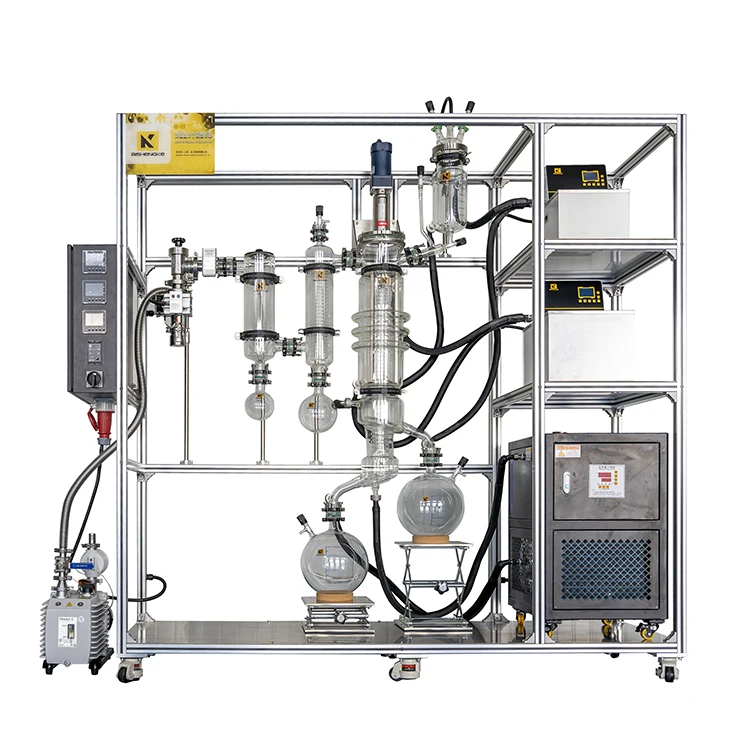

Feeding method: Gear pump for automatic and continuous feeding, speed adjustable Discharging

method: Gear pumps for automatic and continuous discharging, speed adjustable

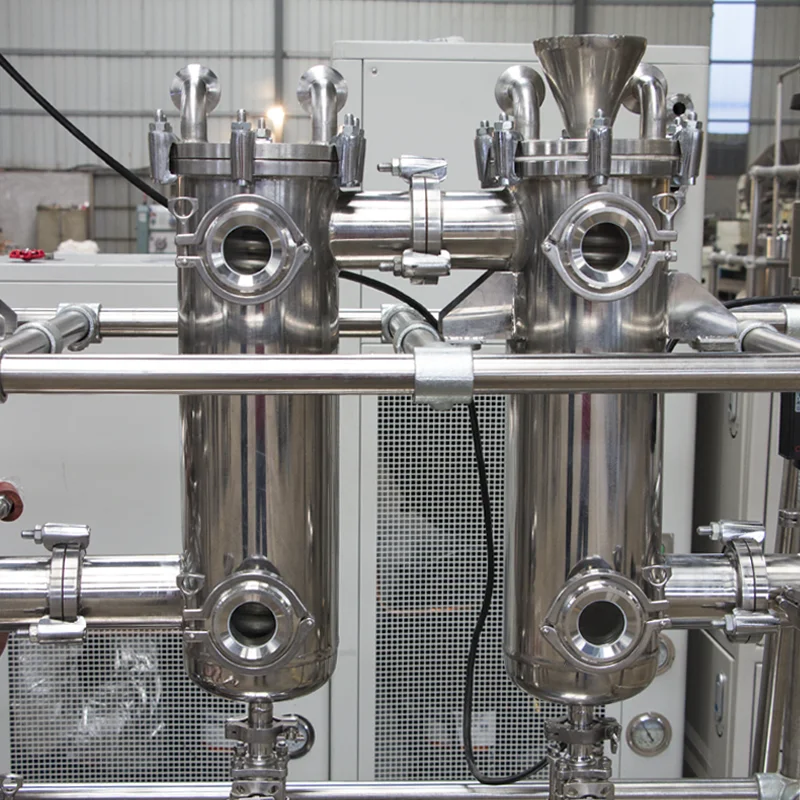

material: Food grade SUS316L (for a section in contact with oil) and Food grade SUS304 (for supporting frame)

Design

Different from the traditional wiped film evaporator design, the condenser is located inside the short path evaporator body.

| Model | LMD-01 | LMD-03 | LMD-05 | |

| Material Tank | Feeding rates(kg/h) | 1to10 | 5to25 | 10to50 |

| CBD throughput(kg/h) | ≈3 | ≈7.5 | ≈15 | |

| Volume(L) | 10L | 30L | 50L | |

| Gear Pump Material Charging | Flow | 1to10 | 5to25 | 10to50 |

| Electronic governor power | 200W | |||

| Evaporator | Evaporation Area | 0.1 | 0.3 | 0.5 |

| Diameter | 125mm(4.9") | 210mm(8.3") | 300mm(11.8") | |

| Height | 1100mm(43.3") | 1750mm(68.9") | 2100mm(82.7") | |

| Film-forming way | Scaper/Roller | |||

| Material | SS316L&PTFE | |||

| Vacuum Seal | Magnetic Seal/Mechanical seal | |||

| Motor(W) | 370 | 750 | 1500 | |

| Speed Regulation Mode(rpm) | Variable Frequency Drive(0-450RPM) | |||

| Max.temperature(℃) | 250℃ | |||

| Dual Cold Trap | Dewar style cold trap and cooling coil cold trap | |||

| Pressure | ≤0.001mbar | |||

| Receiving Flask(L) | heavier component | 2 | 2 | 5 |

| Lighter component | 2 | 2 | 5 | |

| Power | 220V-Single Phase OR Customizable | |||

| Heat Preservation Method | Jacketed Insulation | |||

| Frame Material | SS304 | |||

The material is transported from the feed tank to the jacketed main evaporator. The main evaporator is continuously heated. The built-in scraper scrapes the material evenly into a stream of the liquid film and evaporates instantly. The low-boiling substances begin to gasify and adsorb Above the built-in condensation coil, it flows into the light component receiving a bottle along the outer wall of the condensation tube, and the high boiling point material flows into the heavy component receiving bottle along the inner wall of the main evaporator.

The complete hemp extraction process

Centrifugal extraction- Falling film evaporation- Molecular distillation

Q: Can the mixing motor be replaced with a low-power geared motor?

A: Yes.

Q: What materials can be used in the reactor?

A: The material can be made of carbon steel, 304, 316, etc.

Q: What anti-corrosion treatment can be done inside the reactor?

A: Spray anti-rust paint or spray PTFE layer or lining enamel.

Q: What are the payment methods?

A: Usually we accept wire transfer, Paypal, Western Union, Alibaba International Edition Alipay and so on. The specific payment method can be discussed in the transaction process.

Q: How to transport goods?

A: It depends on the quantity and value of the goods. Usually, we use international express, air and sea.

Похожие товары

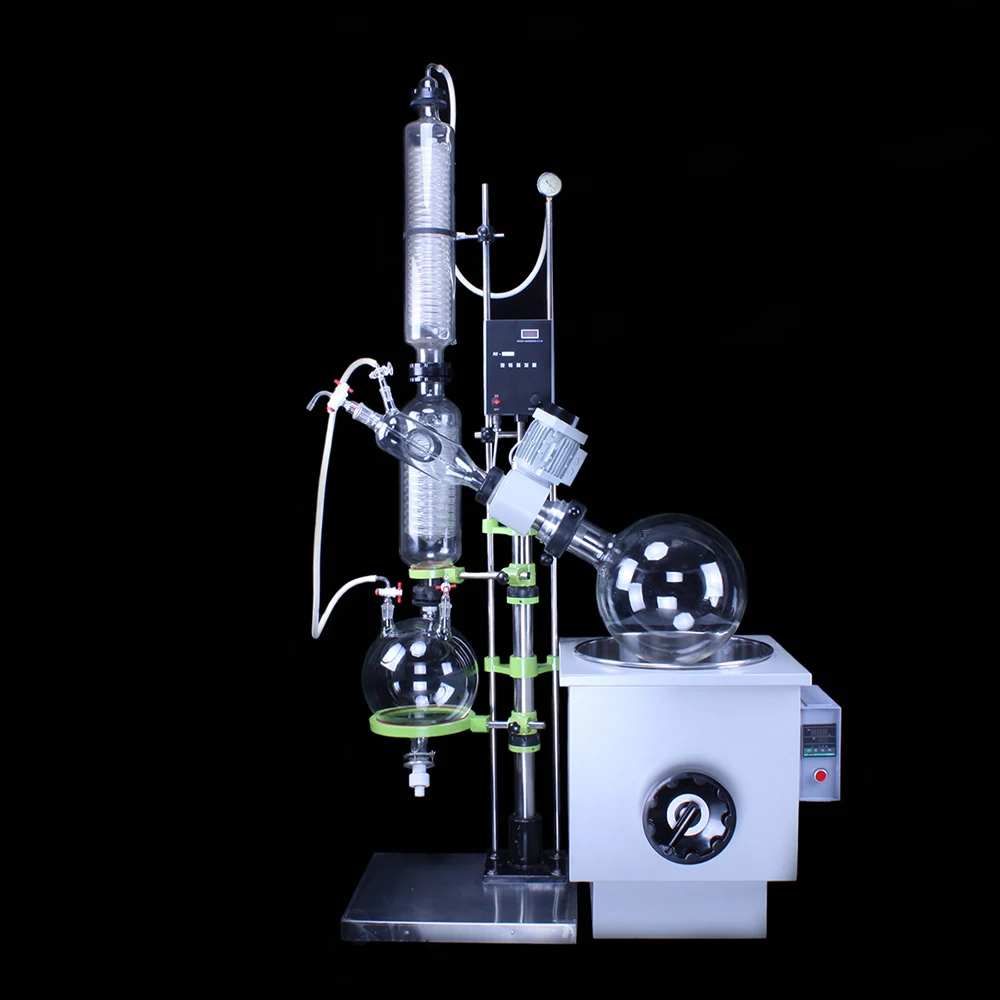

Lab RE-501 роторный цифровой испаритель rotavap 5L

Labrotary использование оптовая Цифровой Роторном Испарителе

Лаборатория дистилляции цифровой дисплей поворотный Vacume Evoparator

Лабораторный цифровой дисплей Rotovapor для паровой дистилляции

5l Мульти-эффект роторный испаритель с цифровым дисплеем

2Л лабораторный цифровой дисплей Мини Вакуумный Ротационный испаритель

Лабораторные весы спиртовой дистилляции цифровой роторный испаритель 10л

Новые поступления

Новинки товаров от производителей по оптовым ценам