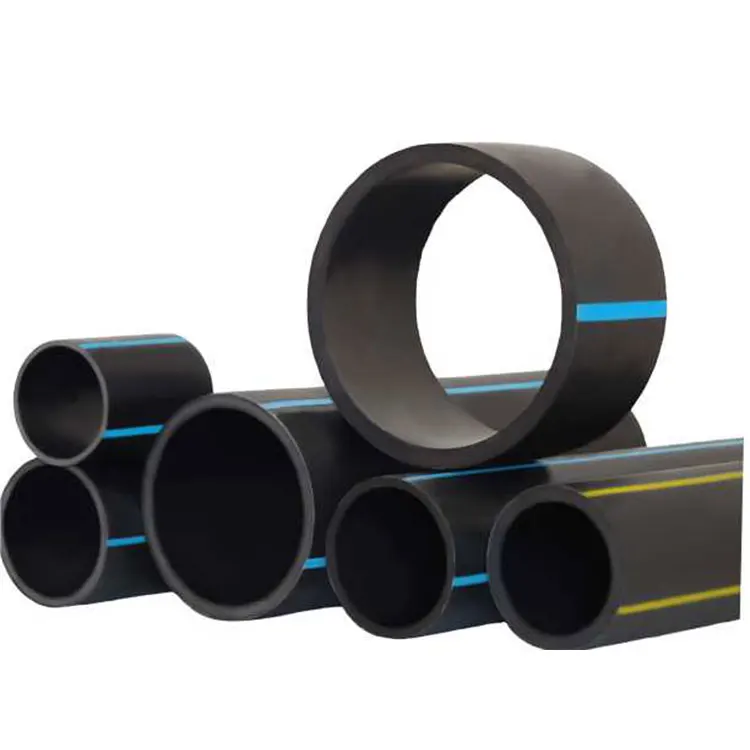

Экструзионная линия большого диаметра пластиковых труб HDPE

- Категория: >>>

- Поставщик: Cissco Machinery Co. Ltd.Cissco Ltd.

Сохранить в закладки 1304807758:

Описание и отзывы

Характеристики

Plastic HDPE Pipe Extrusion Line

PE series plastic pipe extrusion / making / production line is mainly used in the area of agricultural water supply system, architectural water supply system, pavement of cables, etc. This PE PP PPR PE-RT pipe making machine group consists mainly of vacuum calibrating tank, haul-off unit, cutting unit, tilter, etc. single screw extruder and haul-off unit have applied imported A/C inverter, both vacuum pump and driving motor have applied excellent products. The haul-off unit includes two-claw type, three-claw type, four-claw type, six-claw type, eight-claw type, ten-claw type, twelve-claw type, etc. Scraps free cutting, saw cutting or planetary cutting can be applied, the property of machine group is reliable, the production efficiency is high. With special device, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer bulpo pipe, etc, it can also produce PP, PE, ABS, PPR, PEX, silicon core pipe and pipe material of other material. The planetary cutting machine is fully automatic computer digital control, it has such advantages of simple operation, reliable property, etc. It has reached world advanced level.

I. Parameters table of hdpe pipe extrusion machinery

| Pipe diameter | 16-63 | 32-125 | 75-250 | 110-450 | 160-500 | 250-630 | 315-800 | 450-1000 | 630-1200 | 710-1400 | 1000-1600 | 1400-2000 |

| Main extruder | 45/33 | 60/33 | 60/38 | 75/38 | 90/33 | 90/38 | 105/38 | 105/38 | 120/38 | 120/38 | 150/38 | 180/38 |

| Down-stream | LG63 | LG125 | LG250 | LG450 | LG500 | LG630 | LG800 | LG1000 | LG1200 | LG1400 | LG1600 | LG2000 |

| Total power (kw) | 70 | 150 | 230 | 380 | 550 | 550 | 800 | 800 | 1000 | 1100 | 1200 | 1300 |

II. Supply range of hdpe pipe extrusion machinery

| No. | NAME | QTY | REMARK |

| 1 | Single screw extruder | 1 set | Control by PLC |

| 2 | 25/20 single screw co-extruder | 1 set | |

| 3 | Die head and calibrating sleeve | 1 set | |

| 4 | Vacuum sizing tankI | 1 set | |

| 5 | Vacuum sizing tankII | 1 set | |

| 6 | Spray cooling tank | 2 sets | |

| 7 | Haul-off unit | 1 set | |

| 8 | No-scraps Cutting unit | 1 set | |

| 9 | Stacker | 1 set |

III. Pictures of hdpe pipe extrusion machinery

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

CissCo Machinery Co., has been engineering and manufacturing a series of EXTRUSION MACHINERY for more than 30 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

Comparing with the low price low quality machine, please note our strong advantages:

1. 30 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services.

- What's the material of this kind of pipe?

- HDPE;

- Masterbatch;

- What's the pipe diameter range of pipe made by your machine?

- 63-2000mm.

- What's your delivery time of machine?

- 3 months after down payment.

- What's your machine guarantee time?

- 12 months after shipping.

- How many years experiences do you have in this machine manufacturing?

- Around 20 years.

l Contactor: Mr. Louies Liu

l Skype: louies.cissco

l Cellphone/Whatsapp/WeChat: +86 18917527205

l Web: www.cisscomachinery.com

l Add: No. 58, New Jinqiao Road, Pudong, Shanghai, China

Похожие товары

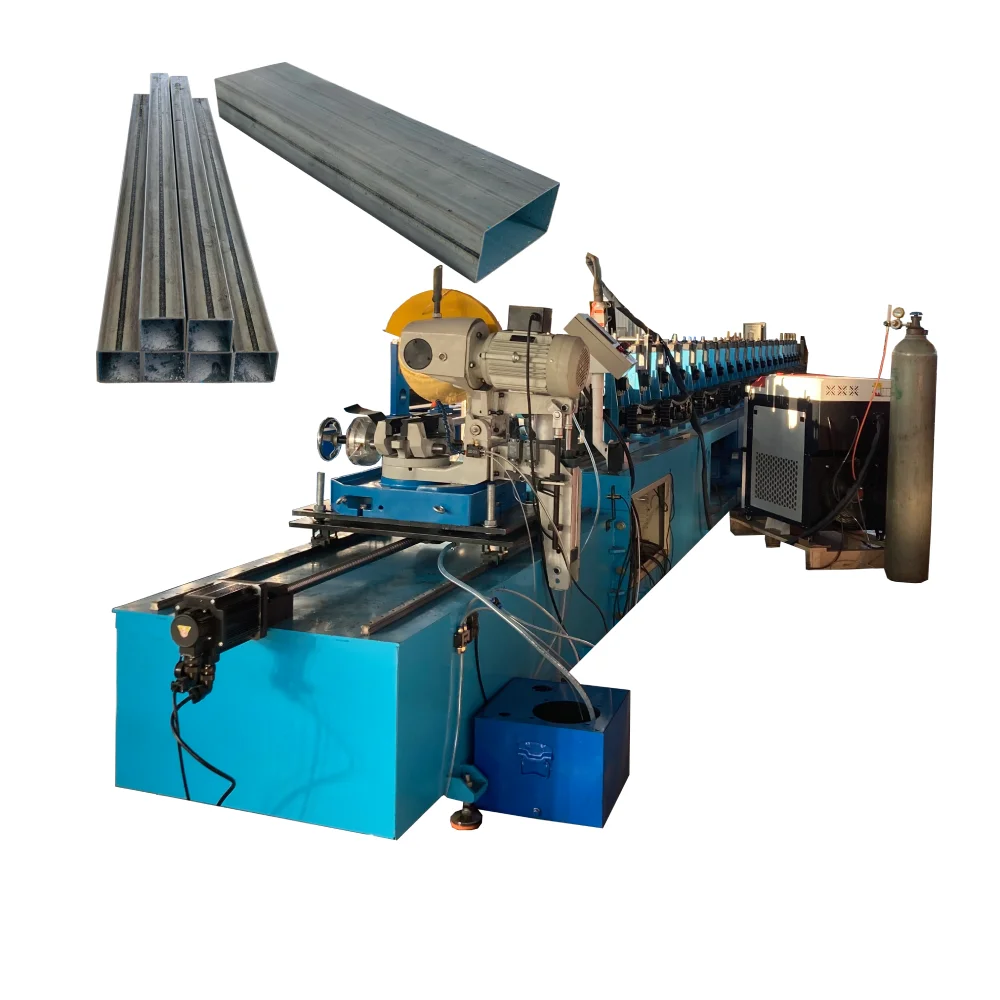

Трубопрокатная мельница большого размера холоднокатаная труба формовочная машина

F150 роликовые долы 1000 кВт HF сварочная труба холодная прокатка для квадратной трубы

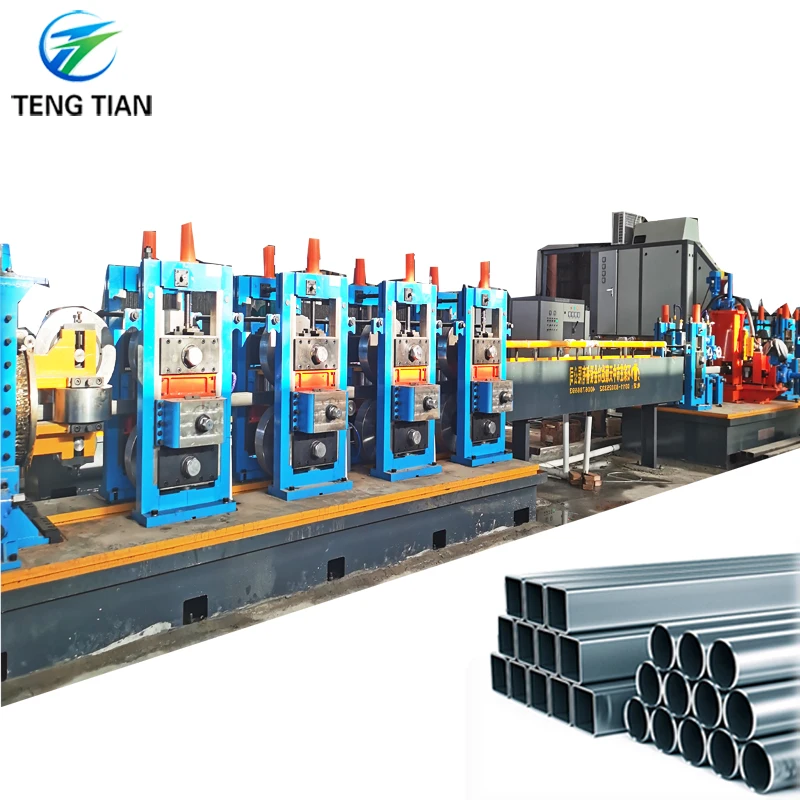

Трубная мельница для эффективного производства труб высококачественное оборудование в промышленности

Высокоточная холодная Летающая пила ms машина для производства стальных труб тиговые трубные мельницы

Автоматическая машина для производства спиральных труб

Оборудование для производства труб завода

Tengtian автоматическое оборудование для производства труб промышленных

Новые поступления

Новинки товаров от производителей по оптовым ценам